A:

It is well known that the edible oil refining process causes loss of refined edible oil. This article will explain what factors are responsible for the loss of refined edible oil and how the loss of refined edible oil in each part is calculated.

A:

The cleaning of cooking oil refining equipment are an essential step in the entire operation of the cooking oil refining equipment. Regular cleaning and maintenance can extend the service life of the cooking oil refining equipment.

A:

Crude vegetable oil usually contains pigment,which leads to crude vegetable oil color too dark,do not meet the standard.Thus,in vegetable oil refining process,it has one step to removethe pigments in the crude vegetable,which we also called bleaching.

A:

The current palm oil fractionation technology can be divided into: dry fractionation of palm oil, solvent fractionation of palm oil and surfactant fractionation of palm oil. This paper focus on palm oil dry fractionation technology and process.

A:

You must heard that chemical refining technology is used for in small scale batch type edible oil refinery plant. Then, do you know whether there is physical refining type mini edible oil refinery equipment?

A:

RBD palm oil can still be further processed into palm olein and palm stearin. If you want to get these two products, that means you need learn about palm oil fractionation process.

A:

If you want to refine crude soybean oil, you need a set of soybean oil refinery machine. As the professional edible oil refinery machine manufacturer, Henan Glory Company can design different kinds of soybean oil refinery machine for you.

A:

Palm oil refining is adopted to deep process crude palm oil by removing impurities like gum, acid, pigment and bad smell. Palm oil refining can be divided into chemical refining and physical refining.

A:

If you want to set up a refined groundnut oil plant, then you need to have sufficient groundnut crude oil, and need to be equipped with deacidification, degumming, decolorization, deodorization and filter machines.

A:

Generally speaking, bleaching is a part of palm oil refining. Only after refining, we will get odourless, yellow and easy to preserve palm oil. Refining including degumming, deacidification, bleaching, deodorization.

A:

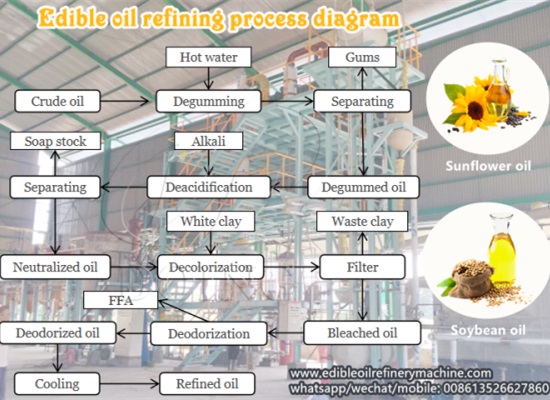

Vegetable oil refining, bleaching and deodorizing process are a complete process for removing different kinds of impurities from crude oil so as to make the crude oil become refined edible oil.

A:

To improve the crude palm oil refining to edible oil conversion rate, you can improve from three points: the quality of crude red palm oil, the process technology of palm oil refining and the capacity of workers' operation.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.