A:

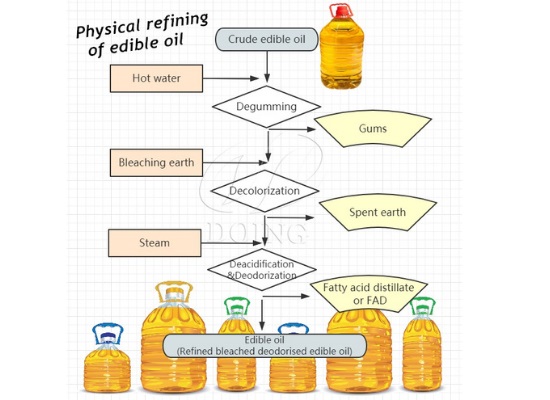

Edible oil refining machine can be used to purify crude edible oil, and the crude edible oil purification process mainly includes six stages: degumming, deacidification, decolorization, deodorization, dewaxing, fractionation.

A:

The selection of edible oil refinery machine needs to be based on the daily processing capacity and economic benefits to choose suitable refinery machine. The price of refinery machine is determined by processing capacity, configuration and the materi

A:

Three tips you must know before selecting cooking oil refining machine, that is the daily processing capacity of your plant, investment budgets and level of machine configuration. Knowing three tips you will be able to choose the most suitable refinin

A:

Edible oil purification process is a procedure of removing the harmful impurities in crude oil and to process crude oil into edible oil. Edible oil purification process contains: degumming, deacidification, decolorization and decolorization and deodor

A:

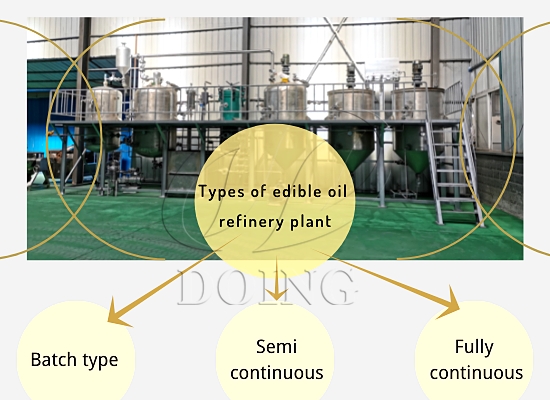

Typically, according to the production scale, investment cost, the purpose of final refined edible oil and detailed refining process, the edible oil refinery plant can be divided into three main types: batch type, semi-continuous type and continuous t

A:

Edible oil refining processes in edible oil refinery plant are to refine the crude cooking oil, get rid of impurities. And then get the high quality edible oil. The common refining processes are degumming, deacidification, decolorization and deodoriza

A:

Nowadays, small scale edible oil refinery plant is becoming more and more popular. It is mainly because of the rapid development of the edible oil refining industry and the unique advantages of small edible oil refinery plants.

A:

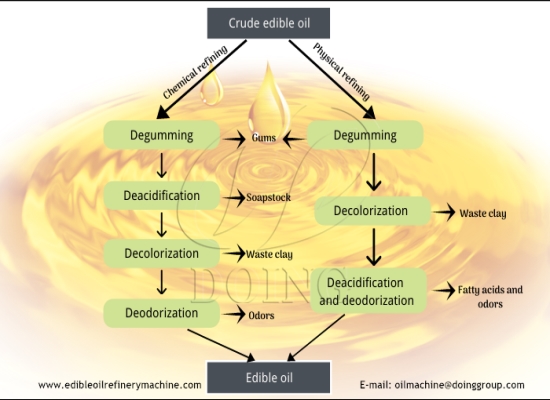

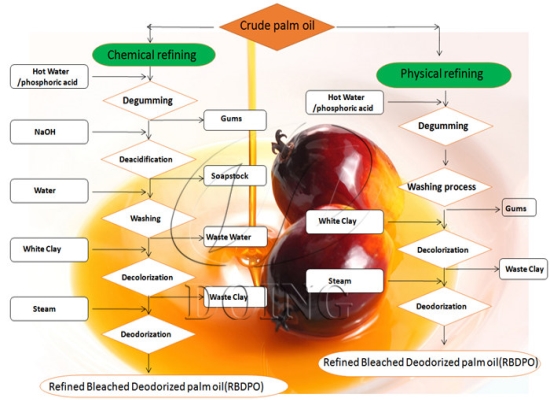

The main difference between the two types of refining method lies in how the FFA are removed. Chemical refining removes the FFA in the neutralizing process while physical refining removes the FFA in the deodorizing process.

A:

From crude cooking oil to edible oil usually need to go through four basic processes, they are: degumming process, deacidification process, decolorization process and deodorization process. Next I will introduce you how to refine crude cooking oil to

A:

Edible oil refining is a relatively complex and flexible process. According to the characteristics of crude edible oil and different uses, edible oil refining methods can be divided into physical refining method and chemical refining method.

A:

Our palm oil refinery palnt can turn the crude palm oil into RBD palm oil through the following process: degumming, neutralization, bleaching, deodorization.

A:

The final vegetable oil specifications are as follows:The Moisture & Volatile matter/ % of 1st grade vegetable oil ≤0.05;The Moisture & Volatile matter/ % of 2nd grade

vegetable oil ≤0.05;

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.