A:

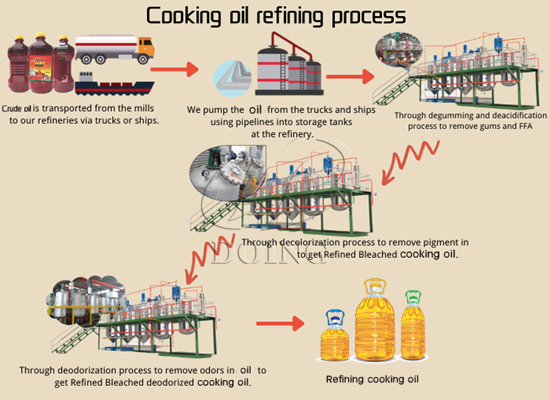

We usually use cooking oil refining equipment to refine and purify crude cooking oil to obtain higher quality cooking oil. How is cooking oil refined and purified? Let's take a look.

A:

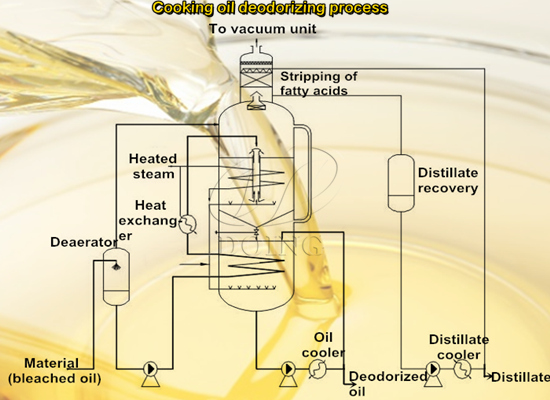

In order to improve the flavor of cooking oil, cooking oil refineries are generally equipped with deodorization tanks to remove the "odor" in cooking oil.

A:

The equipment needed for small scale palm kernel oil refining plant had better be low investment, easy to operate and have cost-effective. So small scale batch type palm kernel oil refining equipment is your best choice.

A:

How to build a small scale cooking oil refinery in India?

1. Determine the raw materials

2. Determine the processing capacity

3. Determine the manufacturer of cooking oil refining machine

A:

The cost of small scale palm oil refining and fractionation machinery is different based on different capacity, configuration, etc. The cost of Glory 2tpd small scale palm oil refining and fractionation machinery is about 60000USD to 100000USD.

A:

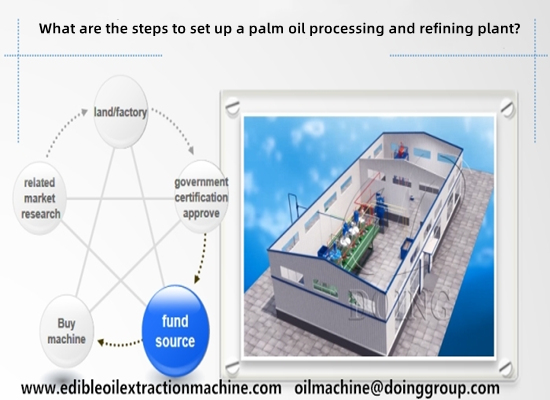

So how to build a palm oil processing and refining plant? Generally speaking, some small scale palm oil production only has the oil extraction section, and some will be equipped with palm oil refineries. It's all based on investment costs and final cr

A:

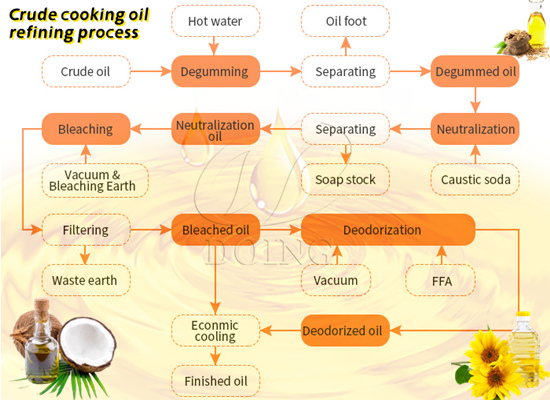

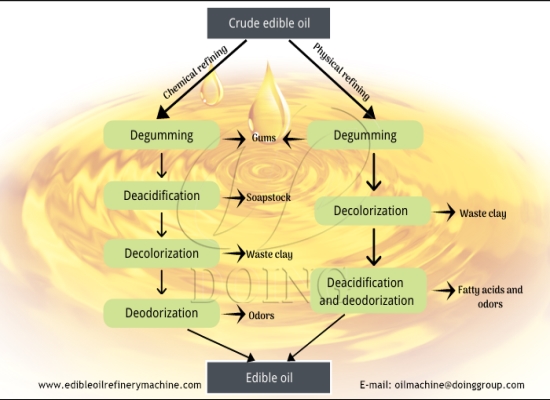

The main purposes of cooking oil refining process is to remove harmful impurities, undesirable odor, flavor, and color in crude cooking oil through degumming, deacidification, decolorization and deodorization process, so that we can obtain pure and re

A:

Red palm oil generally refers to crude palm oil, and the conversion of crude palm oil into refined palm oil requires the participation of palm oi refining equipment. The steps of the palm oil refining process are as follows.

A:

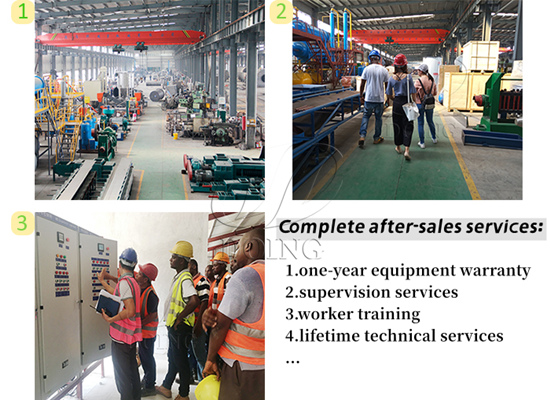

After customers purchase cooking oil refining machine from Henan Glory Company, the services they can obtain mainly include: one-year equipment warranty, equipment installation and commissioning, worker training, and lifetime technical services.

A:

The cost of batch type edible oil refining machine depends on how the machine is heated and how much it can process. The heating methods can be mainly divided into electric heating refining and heat transfer oil refining. The processing capacity varie

A:

The basic steps of cooking oil refining includes four steps of degumming, deacidification, decolorization and deodorization.Henan Glory Company can provide high quality and high efficiency cooking oil refining machine.

A:

More and more people want to start palm oil refining business in Nigeria. So how many budget is needed to start a palm oil refining business in Nigeria?

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.