A:

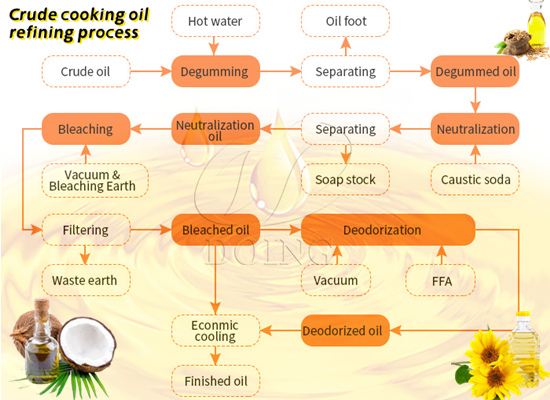

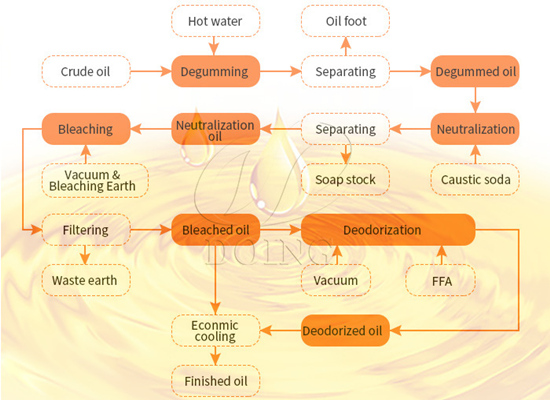

Cooking oil refining includes the steps of degumming, deacidification, decolorization and deodorization, which can remove the impurities, gums, soapstock, odor and pigment in the cooking oil, make the oil clear and translucent, and improve the taste o

A:

An aspiring entrepreneur must be able to look wide and deep when investing in a business. This article covers everything you need to know about why so many people choose to set up palm oil refinery plant in Nigeria? and how to set up a palm oil refine

A:

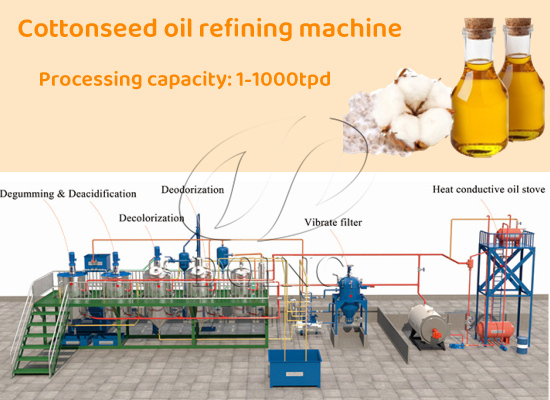

Cottonseed oil is one of the most common edible oils in the world. We all know that crude cottonseed oil needs refining before it can be eaten. Then what is the refining process and what is the purpose of refining? Let’s have a look.

A:

Refined sunflower oil is clear and free of impurities, has high nutritional value, and has a broad market. However, how to choose sunflower oil refining equipment? Henan Glory Company gives you the answer!

A:

The answer is yes, a cooking oil refining plant can handle all kinds of crude oils, because the purpose and process of cooking oil refining are the same.

A:

The price of cooking oil refining machine will be affected by the following four aspects: crude oil, processing capacity, equipment materials, degree of automation and so on.

A:

How much does it real cost to build an edible oil refining plant? Whether you are a beginner looking to invest in a edible oil refining plant or a veteran looking to expand your edible oil refinery business, you will find the answer you are looking fo

A:

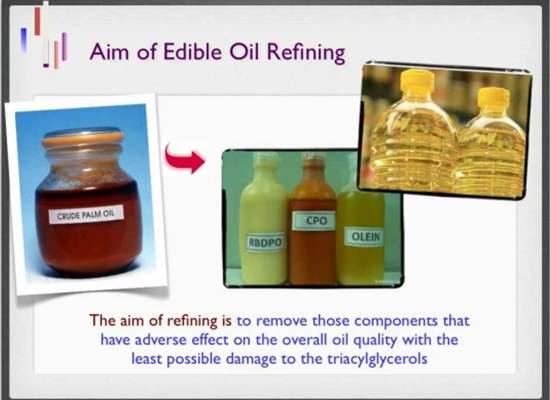

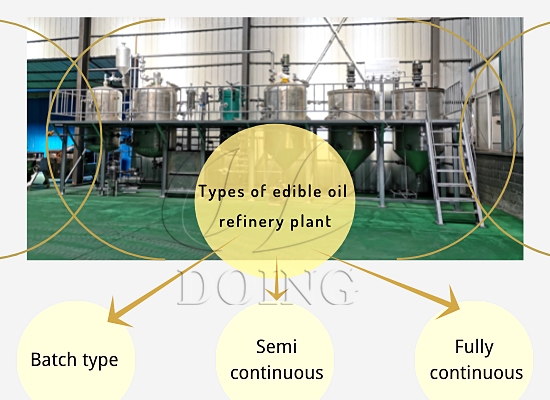

The purpose of edible oil refining is to remove impurities unwanted and harmful impurities from crude oil to obtain refined oil that meets certain quality standards.

A:

Nowadays due to the international situation, the edible oil price has risen sharply, bringing huge business opportunities to the edible oil production industry, many people want to seize this opportunity to engage in the edible oil production industry

A:

Refining crude cooking oil into edible oil is inseparable from cooking oil refining equipment and cooking oil refining process. And the whole cooking oil refining process mainly contains four steps, respectively degumming, deacidification, decolorizat

A:

The crude peanut oil purification process includes four steps: degumming, deacidification, decolorization and deodorization. The peanut oil purified by Henan Glory's peanut oil purification machine has high quality and bright color.

A:

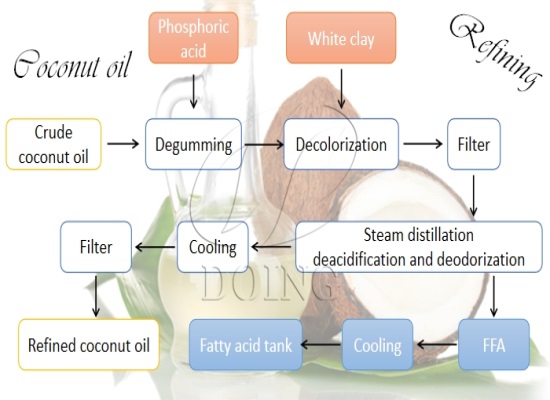

There are mainly four steps involved in coconut oil refining process: degumming, deacidification, decolorization and deodorization. For different coconut oil refining capacity, we may adopt different kinds of coconut oil refining equipment.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.