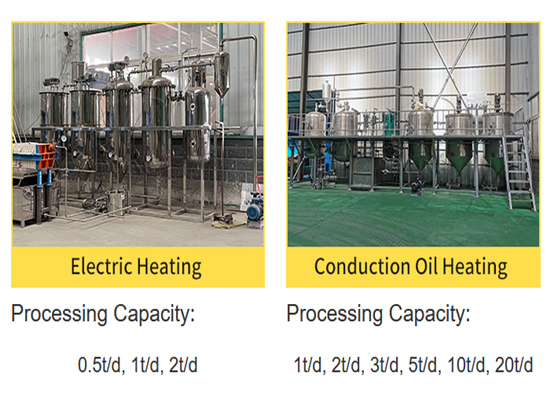

Q:Electric heating cooking oil refining machine VS conduction oil heating cooking oil refining machine

A:

About cooking oil refining machine, we have electric heating cooking oil refining machine and conduction oil heating cooking oil refining machine. two different heating refining machine, what is the difference between them?

A:

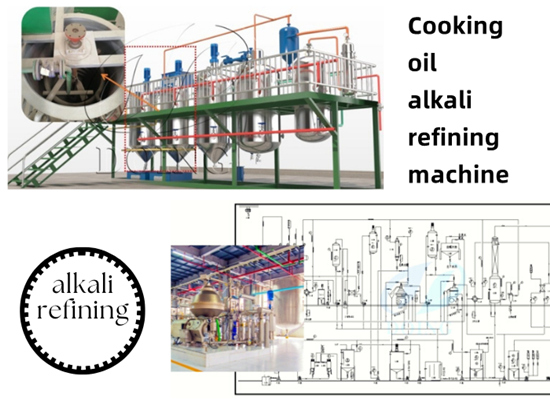

The deacidification method of cooking oil alkali refining is to neutralize the free fatty acids in the oil with alkali, and then generate saponins.

A:

Palm oil refining process include degumming, deacidification, decolorization and deodorization. Refined palm oil can be gotten after that. In addition, according to the needs of different customers, palm oil can be further extracted into palm olein an

A:

Usually, we choose to add sodium hydroxide for alkali refining and deacidification, so how much caustic soda is needed to refine 1 liter of cottonseed oil?

A:

Which cooking oil refining machine is suitable for small workshops? It mainly depends on your daily processing capacity. Glory Company can design and produce three kinds of cooking oil refining machine: batch type, semi-continuous type and full contin

A:

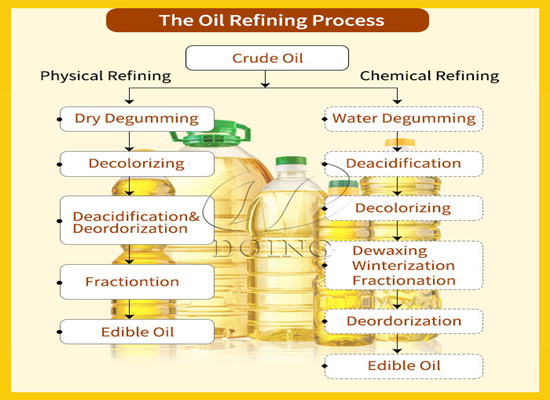

There are also great differences between the two refining methods. Next, we mainly introduce the differences between the two refining methods from two aspects: the applicable types of crude oil and the processing technology.

A:

In order to produce well refined sunflower oil, we need to know what are the factors that affect the production of refined sunflower oil. The first is the quality of crude sunflower oil, and the second is the quality of sunflower oil refining machine.

A:

This video shows us different types of cooking oil refining machine as well as cooking oil fractionation machine.

A:

Therefore, in order to remove these impurities, the refining of crude oil will be divided into four sections: degumming, deacidification, decolorization and deodorization.

A:

After the palm fruit is pressed, the crude red palm oil is obtained, but to obtain edible palm oil, it needs to be refined to meet the edible standard.So how to build a batch type palm oil refinery with a fractionation plant?

A:

Opening an cooking oil refining plant has become a dazzling entrepreneurial and profitable project among many entrepreneurial projects. So, what is the easiest way to start an cooking oil refining plant?

A:

As we all know, more refined palm oil is now on the market, which is generally welcomed by everyone.If you are just starting out in the palm oil refining industry, where can you learn the specifics of palm oil refining?

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.