Affecting factors of cooking oil alkali refining

The deacidification method of cooking oil alkali refining is to neutralize the free fatty acids in the oil with alkali, and then generate saponins. In order to achieve better results, the following factors need to be paid attention to in the process of cooking oil alkali refining:

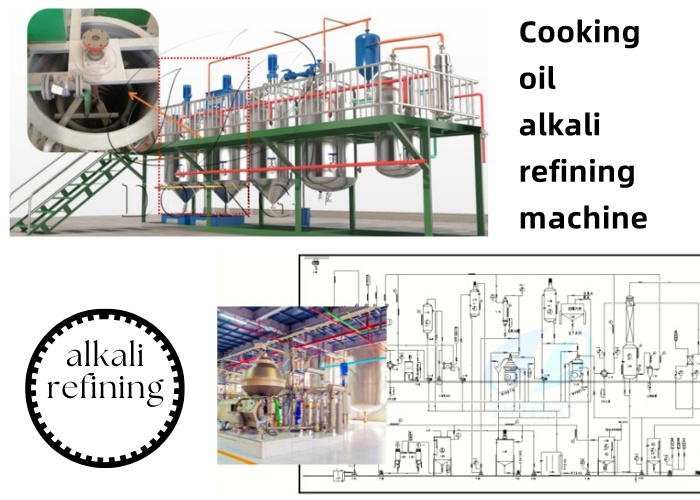

Cooking oil alkali refining process

Cooking oil alkali refining process

1. Types of bases used

The alkalis used to neutralize free fatty acids include sodium hydroxide, sodium carbonate and calcium hydroxide. Various alkalis have different technological effects in cooking oil alkali refining. Sodium hydroxide and sodium carbonate are generally used in the production of oil industry, because of their strong alkalinity, the saponin generated by the reaction can be separated from the oil well, the deacidification effect is good, and the oil has a high decolorization ability.

2. Dosage of alkali

The amount of alkali directly affects the effect of cooking oil alkali refining. The amount of alkali is insufficient, the neutralization of free fatty acids is incomplete, some impurities in the cooking oil cannot be fully adsorbed, and the soap particles cannot be flocculated well, resulting in difficult separation, poor quality of alkali refining refined oil, and low oil yield. With too much alkali, the neutral oil is saponified and the refining loss increases. Therefore, it is very important to correctly grasp the amount of alkali used.

3. Lye concentration

Appropriate lye concentration is one of the important factors to obtain better results in caustic refining of cooking oil. Therefore, Henan Glory Company recommends that you should conduct a comparative experiment with different concentrations of lye before caustic refining, so as to choose the most suitable lye concentration.

4. Operating temperature

The influence of the operating temperature of cooking oil alkali refining on alkali refining is mainly reflected in the initial temperature, final temperature and heating rate of alkali refining. It is a factor related to the quality of crude cooking oil, alkali refining process and alkali concentration. Taking the batch caustic refining process as an example, when the crude cooking oil quality is good, a higher operating temperature can be used when using low-concentration lye caustic refining; otherwise, the operating temperature should be lower.

Henan Glory Company can provide you with professional cooking oil alkali refining process and equipment. If you have any questions or needs, please feel free to contact us!

PREV:Electric heating cooking oil refining machine VS conduction oil heating cooking oil refining machine

Leave a message

If you wanna to get more details about Affecting factors of cooking oil alkali refining, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company