A:

The main impurities removed during the processing of edible oil refinery machine include solid impurities & suspended particles, phospholipids (gums), free fatty acids (FFA), coloring pigments, off-flavors and odors, waxes and sterols, etc.

A:

Batch type sunflower oil refining equipment, Henan Glory’s offering for small-medium edible oil producers with ≤20TPD capacity, has low investment and flexible operation—ideal for multiple crude oil varieties.

A:

To ensure groundnut oil quality, groundnut oil refining machine is key—it solves common issues of crude groundnut oil (turbidity, off-odor, short shelf life). We also provides tailored machines for groundnut oil plants with different daily capacities.

A:

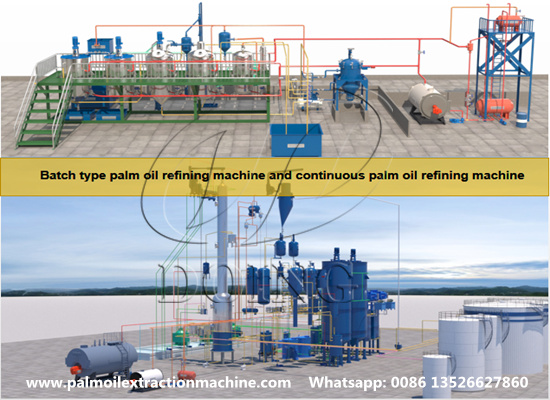

Whether you’re expanding your current operation or building a new production line, having the right machine for refining palm oil is crucial to delivering clean, stable, and market-ready palm oil.

A:

The components of sunflower oil refinery plant include sunflower oil degumming, deacidification (neutralization), decolorization (bleaching), deodorization, dewaxing section and sunflower oil filtration & packaging Line.

A:

A 10tpd crude cooking oil refining line includes degumming equipment, deacidification equipment, decolorization machine, deodorization machine, filtration machine, heat conducting oil furnace and steam generator.

A:

The soybean oil refining process transforms crude oil through distinct stages of degumming, deacidification, decolorization and deodorization into a versatile, stable, nearly flavorless, light-colored oil meeting stringent food quality standards.

A:

The main purposes of palm oil refining process is to obtain pure and relatively non-impurities of high-quality edible oil. The palm oil refining equipment includes degumming equipment, deacidification equipment, decolorization equipment and deodorization

A:

Whether you are a small palm oil producer or a large industrial palm oil refining plant, Henan Glory's advanced palm oil refining system can help convert your crude oil into high-quality palm oil.

A:

The poor edible oil deodorization design not only affects the quality of oil products and brand image, but may also lead to increased costs, reduced production efficiency and loss of market opportunities.

A:

Crude palm oil contains impurities that affect taste, shelf life, and safety. The importance of palm oil refining is as follows, extending the storage time of palm oil, good for health, increasing profits, etc.

A:

Many factors should be paid attention to when purchasing edible oil refining equipment: production capacity, processing technology, and equipment supplier etc, which will help customers find suitable edible oil refining equipment.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.