A:

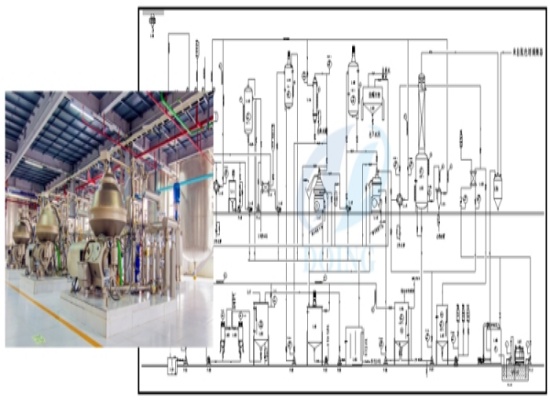

The refining units play a crucial role in the edible oil extraction process. Its main function is to deeply process the crude or semi-refined oil to remove impurities, undesirable pigments, and odor substances,improving the purity, taste, and quality of t

A:

The edible oil refining is often considered a low-margin business because of edible oils' commodity nature, high competition, price volatility of raw materials, high operating costs and low value-added differentiation, etc.

A:

Crude oil refining work involves four steps: degumming, deacidifying, decolorizing, and deodorizing, aiming at removing impurities, enhancing taste, and improving the stability of cooking oil.

A:

The importance of edible oil refining is mainly reflected in the following aspects: Improving safety and quality of edible oil, enhancing nutritional value of edible oil, extending shelf life of edible oil and meeting consumer preferences.

A:

Oil dewaxing treatment process is mainly for those oils that are easy to precipitate wax at low temperature, such as sunflower oil, rice bran oil, corn embryo oil, cottonseed oil, tea seed oil, etc.

A:

By removing phospholipids and other impurities, the edible oil degumming process provides purer raw materials for subsequent refining steps, ensuring that the final edible oil can meet consumer demand in terms of taste, appearance, nutrition and safety.

A:

The cost and timeline to build an oil refinery are closely related to varies, such as the refining capacity, machine, technological complexity, and the type of products to be produced.

A:

Soybean oil refinery plant designed to remove impurities, and improve the stability of soybean oil. The components of a soybean oil refinery plant include degumming, deacidification, decolorization , deodorization.

A:

Starting a sunflower oil refining business requires five parts, namely conducting market research and analysis, purchasing high-quality crude sunflower oil, establishing sunflower oil refining production processes and marketing your sunflower oil, etc.

A:

There are several common misunderstandings when choosing edible oil refining equipment that people often encounter, such as the prioritizing low price exclusively, neglecting energy consumption, underestimating maintenance requirements, etc.

A:

Crude cooking oil needs refining because in its unrefined state, it contains impurities such as free fatty acids, phospholipids, pigments, and odors that can affect the quality, flavor, and shelf life of the final product.

A:

Choosing the right palm oil refining machine requires considering the following factors: refining capacity, refining process type, equipment automation and control functions, equipment energy efficiency, etc.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.