A:

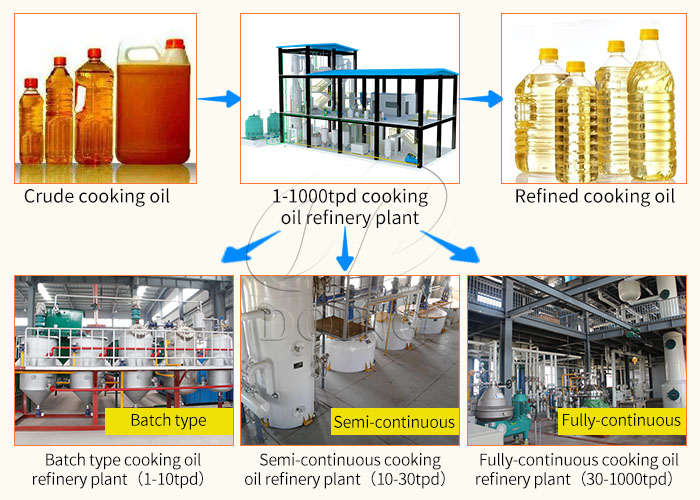

A complete edible oil refinery plant can be divided into pretreatment part, degumming part, deacidification part, decolorization part, decolorization filtration part, deodorization part, heat conductive oil system, outdoor tanks area, etc.

A:

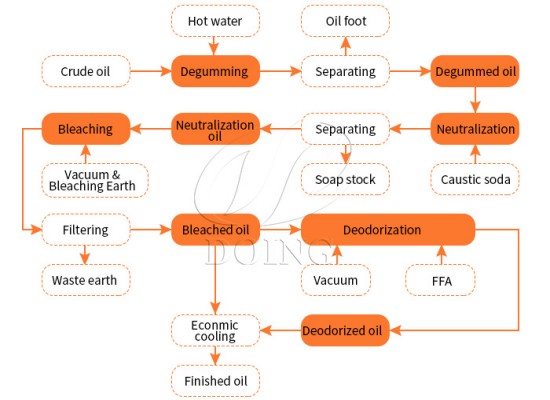

Cooking oil chemical refining is a common method used in the industry. The main purpose of chemical refining is to remove the FFA by an alkaline solution and remove other impurities at the same time.

A:

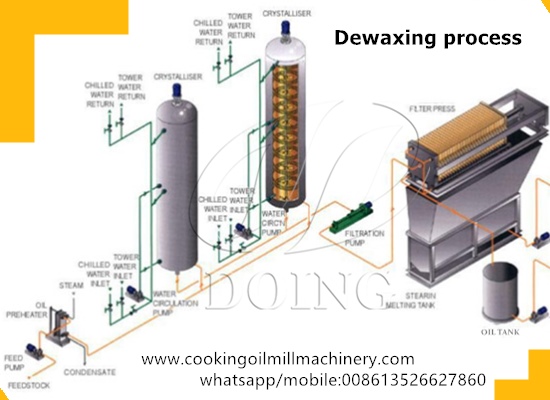

Sunflower oil dewaxing is to remove the wax content in crude sunflower oil. The process of sunflower oil dewaxing is divided into four steps: heating, cooling, crystallization, filtration.

A:

The process of producing refined edible oil involves four steps: degumming, deacidifying, decolorizing, and deodorizing, aiming at removing impurities, enhancing taste, and improving the stability of edible oil.

A:

First of all, you need to have enough funds. Secondly, you need to choose a professional manufacturer to provide you with cooking oil refining machines. Finally, you need a customs declaration department to help you import the cooking oil refining machine

A:

Do you know why do edible oils need the refining process? The edible oil refining process has many advantages, such as improving its appearance and taste, removing its harmful substances, and meeting food safety standards.

A:

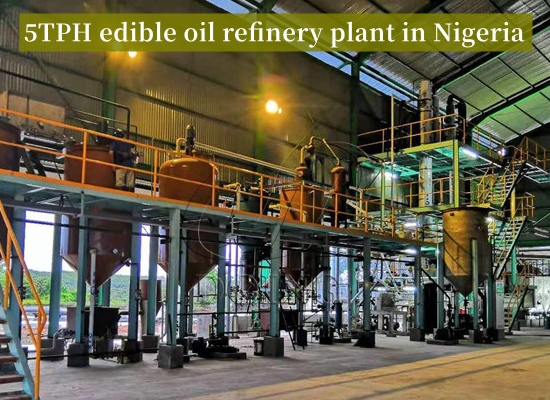

The edible oil refining business has high profits and low risks.This article will analyze for you whether it is profitable to invest in an edible oil refinery plant in Nigeria from both raw materials and equipment.

A:

How to start an edible oil refining business? 1. Determine your processing capacity; 2. Understand the market; 3. Establish edible oil refining area;4. Obtain the necessary permissions and licenses.

A:

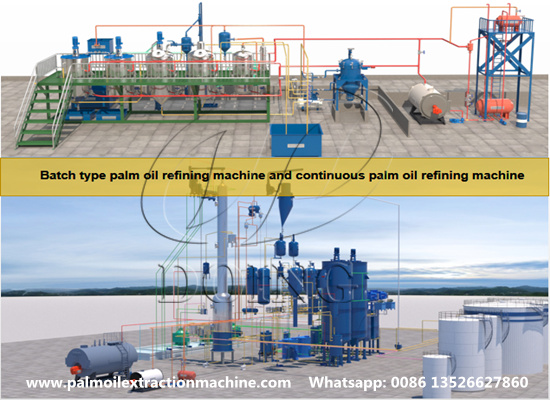

Doing Holdings-Henan Glory's palm oil refining machine includes batch type edible oil refining machine, semi-continuous edible oil refining machine and fully continuous edible oil refining machine.

A:

The edible oil refined by 2 ton per day edible oil refining machine can meet the national standards for edible oil.The price of 2 tons per day edible oil refining machine is about US$13,000-50,000.

A:

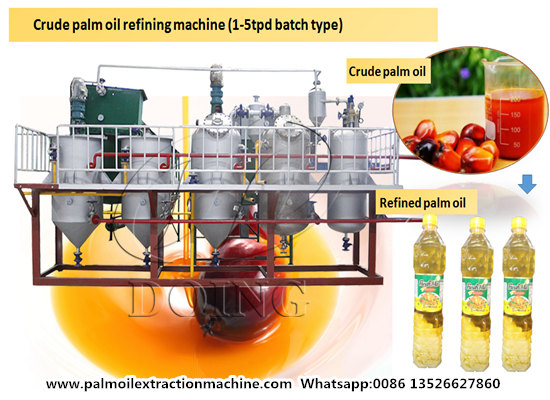

The production capacity of batch type palm oil refining machine is 1-20TPD; semi-automatic palm oil refining machine is 20-50TPD; the continuous palm oil refining machine is used for production capacity above 50TPD.

A:

The most suitable palm oil refining equipment for a 20tpd palm oil refinery plant is batch palm oil refining equipment. But if you want to pursue long-term comprehensive benefits in the future, semi-continuous palm oil refining equipment and continuous p

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.