A:

If your goal is to improve efficiency, consistency and scalability of cooking oil refining while reducing labor costs, investing a fully automated cooking oil refining system may bring you significant long-term benefits.

A:

Edible oil decolorization units play a critical role in edible oil refining processes by significantly improving oil purity and extending shelf life through targeted removal of impurities and enhancement of oxidative stability.

A:

Activated clay is crucial in edible oil decolorization process because it has superior adsorption capacity for pigment removal, can remove oxidation products and impurities and enhance edible oil safety and compliance, etc.

A:

The step-by-step maintenance plan for prolonging edible oil refinery system lifespan includes regular inspection and monitoring, system cleaning and filtration equipment maintenance, lubrication of the moving parts of the oil refinery system, etc.

A:

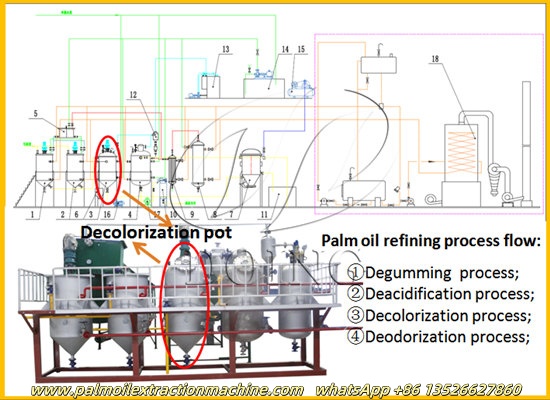

Edible oil refining is a process of deep processing crude oil by using edible oil refining equipment through steps such as degumming, deacidification, decolorization, and deodorization. It can remove impurities in crude oil.

A:

Efficient operation of agricultural edible oil degumming and deacidification equipment is crucial to ensure high quality oil and maximize production yield. With this troubleshooting guide, you can maximize the efficiency of your equipment.

A:

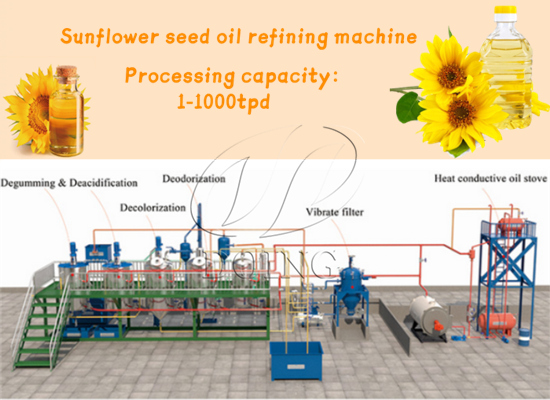

The sunflower oil refining process technologies mainly include several stages: degumming, deacidification, decolorization, deodorization, and dewaxing.

A:

Decolorization is one of the important steps of edible oil refining. Too long or too short decolorization time will affect the effect of refined oil refining. Therefore, it needs to be a balance between time and effect.

A:

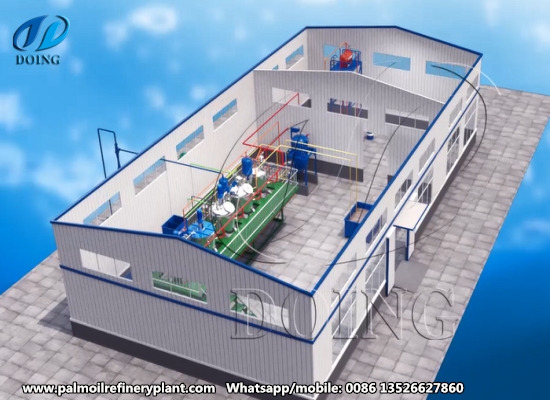

Tips for setting up a vegetable oil refining production line include assess market and oil type, choose the right vegetable oil refining equipment, establish energy efficiency and waste management systems, establish a quality control system, etc.

A:

The key considerations for setting up a vegetable oil refinery plant includes: market demand and research, choosing the right location, plant capacity and machinery requirements, raw material sourcing and storage, compliance and certification etc.

A:

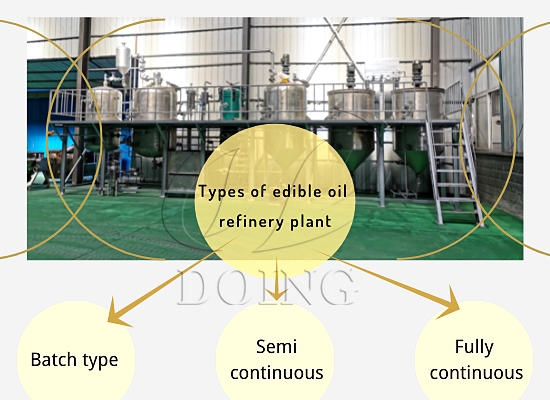

The difference among three types of cooking oil refining machines is mainly reflected in the following aspects: processing capacity, degrees of automation, investment cost, product quality stability and degrees of energy loss.

A:

Environmental issues should be paid attention to during edible oil refining including wastewater treatment and recycling, waste gas emission and odor control, and treatment and utilization of solid waste, etc.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.