What's the difference among three types of cooking oil refining machines?

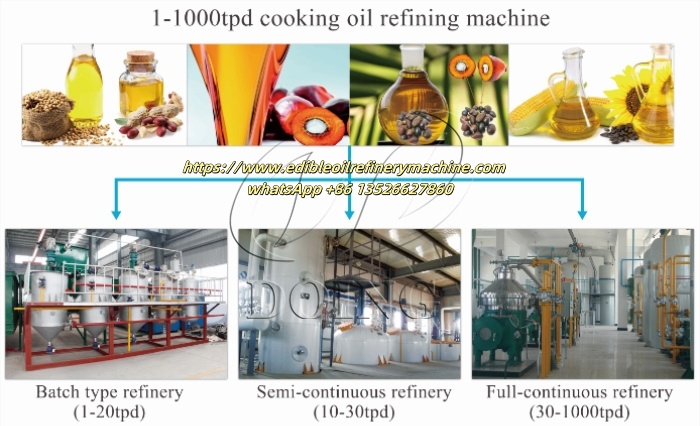

There are three common types of cooking oil refining machines, namely batch type cooking oil refining machine, semi-continuous cooking oil refining machine and fully-continuous cooking oil refining machine. Their differences are mainly reflected in the following aspects:

1. Different Processing Capacity:

(1) Batch type cooking oil refining machine: suitable for small scale cooking oil refineries with a capacity of 0.5-20t/d;

(2) Semi-continuous cooking oil refining machine: suitable for medium scale cooking oil refineries with a capacity of 20-50t/d;

(3) Fully-continuous cooking oil refining machine: suitable for large scale cooking oil refineries with a capacity of more than 50t/d or even 100t/d;

Three types of cooking oil refining machines with different processing capacities

Three types of cooking oil refining machines with different processing capacities

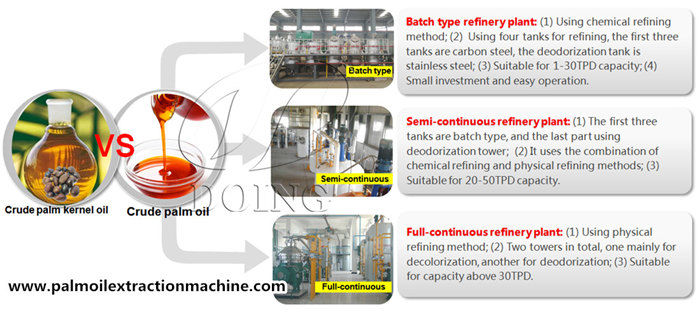

2. Different Degrees of Automation:

(1) Batch type cooking oil refining machine: low degree of automation and high labor intensity.

(2) Semi-continuous cooking oil refining machine: The degumming and decolorization sections are batch production, and the deacidification and deodorization sections are continuously produced using the deodorization tower process;

(3) Fully-continuous cooking oil refining machine: Continuous production, high degree of automation and low labor intensity.

Characteristics of three types of palm oil refining machines

Characteristics of three types of palm oil refining machines

3. Different Investment Costs:

(1) Batch type cooking oil refining machine: Simple structure and low investment cost;

(2) Semi-continuous cooking oil refining machine: Add other auxiliary machines, and the investment cost is higher than that of batch type cooking oil refining machine.

(3) Fully-continuous cooking oil refining machine: The requirements and configuration of the machine are relatively high, so the investment cost is high.

4. Different Product Quality Stability:

(1) Batch type cooking oil refining machine: Affected by the operating technology level and the changes in various raw materials, the quality of the obtained products is unstable;

(2) Semi-continuous cooking oil refining machine: Through partial automation and continuous production, the stability of product quality is improved to a certain extent.

(3) Fully-continuous cooking oil refining machine: The production process is continuous and stable, which effectively ensures the stability of product quality.

Various refined cooking oils

Various refined cooking oils

5. Different Degrees of Energy Loss:

(1) Batch type cooking oil refining machine: Each section needs to be restarted, so the energy loss is relatively large;

(2) Semi-continuous cooking oil refining machine: The cooking oil deodorization section can reduce some losses.

(3) Fully-continuous cooking oil refining machine: High production efficiency and relatively low energy loss.

Above is the difference among three types of cooking oil refining machines. As a company specializing in cooking oil refining machines, and our engineers can help you design the entire cooking oil refining process according to your capacity and requirements. We can provide you cooking oil refining machines, cooking oil refining process flow diagram, cooking oil refining layout design and cooking oil refining project installation training guide, etc. If you are interested in cooking oil refining business, please contact us.

PREV:Key considerations for setting up a vegetable oil refinery plant

NEXT:What environmental issues should be paid attention to during edible oil refining?

Leave a message

If you wanna to get more details about What's the difference among three types of cooking oil refining machines?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

-

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company

-

What is a comprehensive guide to setting up the best cpo refinery plant?

What is a comprehensive guide to setting up the best cpo refinery plant?

-

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

-

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria