Continuous groundnut oil refining plant

Continuous groundnut oil refining plant utilizes physical oil refining method to make extracted crude groundnut oil into first grade groundnut oil. The advanced equipped continuous groundnut oil refining plant is low refining loss rate, and high oil yield rate.

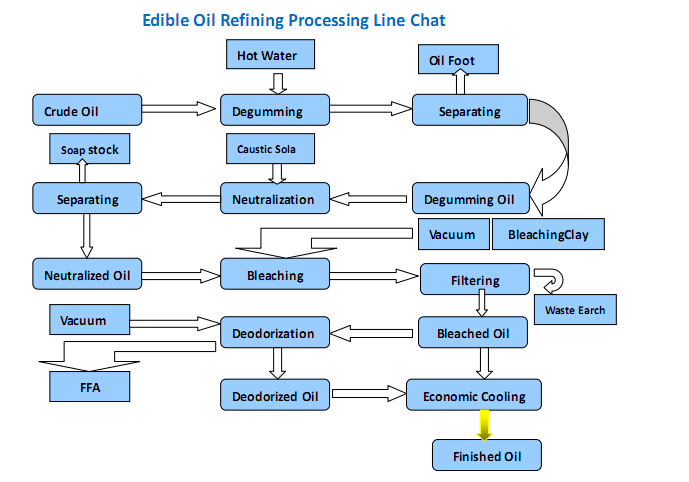

Process flow chart of groundnut oil refining plant:

Groundnut oil refining process flow chart

Groundnut oil refining process flow chart

Groundnut oil refining process is to remove some substances that do harm to humanbeings or effect the soybean oil quality. Continuous groundnut oil refining plant can reduce refining losses and increase refined groundnut oil production quantity.

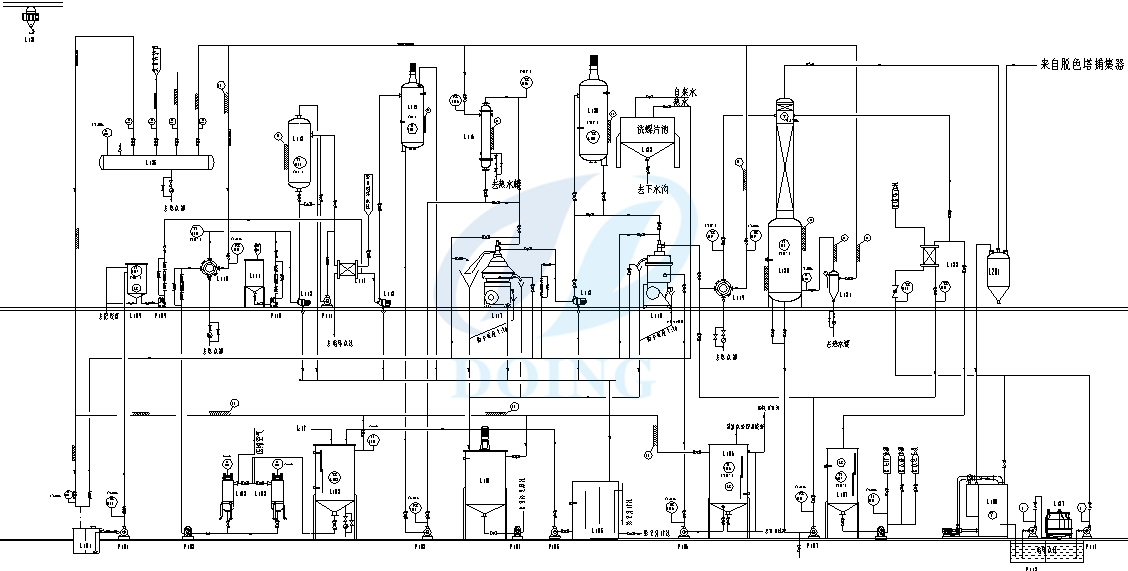

Degumming:

Degumming and deacidification process flow chart of groundnut oil refining plant

Degumming and deacidification process flow chart of groundnut oil refining plant

Intermittent process preheats groundnut crude oil to 80 ~ 85 ℃. The amount of water in crude oil bases on colloid content, and generally 3-5 times of the gum content, water temperature at 85 ~ 90 ℃ (5 ℃ higher than oil temperature). Finish water adding in 40-60min, along with 60-70r/min stirring, continue stirring 3-5min after adding water, and stand for precipitation 2-4h.

Vacuum drying:

Heat degummed vegetable peanut oil to 25 ~ 135 ℃, dehydrated into a vacuum dryer 20 ~ 30 min. Moisture of dehydrated oil is less than 0.1% (after degumming of crude oil via the oil contained in the 0.3% to 0.5 % of the water will affect the adsorption capacity of bleaching clay section).

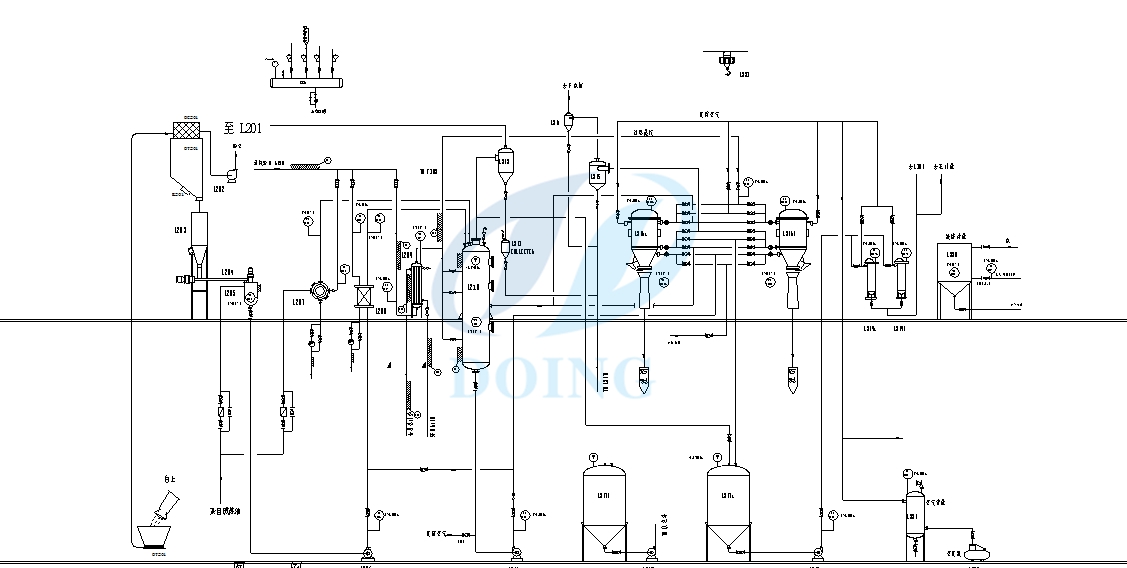

Decolorization:

Decolorization process flow chart of groundnut oil refining plant

Decolorization process flow chart of groundnut oil refining plant

Degumming of groundnut oil can remove grease in oil pigment to improve oil color, adsorption of aflatoxin and trace metals, phospholipids, other gum and other impurities. It ensures high quality of groundnut oil and improves oil stability.

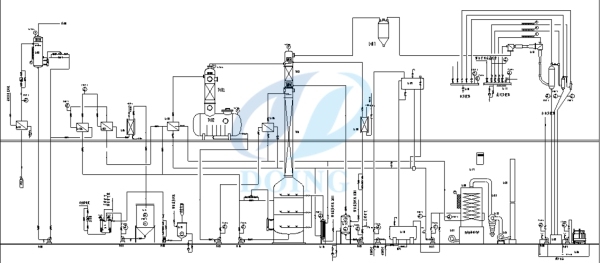

Deodorization:

Deodorization process flow chart of groundnut oil refining plant

Deodorization process flow chart of groundnut oil refining plant

Control oil temperature to 250 ~ 270 ℃ when decolorized peanut oil enters into deodorizer, in direct steam injection, the free fatty acids, ketones, aldehydes and other impurities are removed from the oil, the thermal decolorized action also occurs, and the pigment composition is cleaved distilled from the oil. Deodorized vacuum (absolute pressure) controlled at 266 Pa, the deodorization time is about 2h.

Our continuous edible oil refinery plant project in Kenya, used for refining palm oil

Our continuous edible oil refinery plant project in Kenya, used for refining palm oil

This is one of our edible oil refinery plant project cases. Henan Doing Company is a professional manufacturer who has very rich experience in manufacturing edible oil refinery machine. The groundnut oil refining plant is just one of our products. Our engineers can design for you and help you to install your soybean oil refinery plant. Leave your requirement, and we can operate with you to set up your soybean oil refinery plant.

Leave a message

If you wanna to get more details about Continuous groundnut oil refining plant, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?