What are the components of sunflower oil refinery plant?

If you're looking to produce high-quality, edible-grade sunflower oil, investing in a professional sunflower oil refinery plant is the key to unlocking maximum value from your crude oil. A complete sunflower oil refinery plant is a sophisticated system designed to remove impurities, enhance oil stability and meet food safety standards. But what exactly makes up a sunflower oil refinery plant? Let’s take a closer look.

1. Sunflower Oil Degumming Section

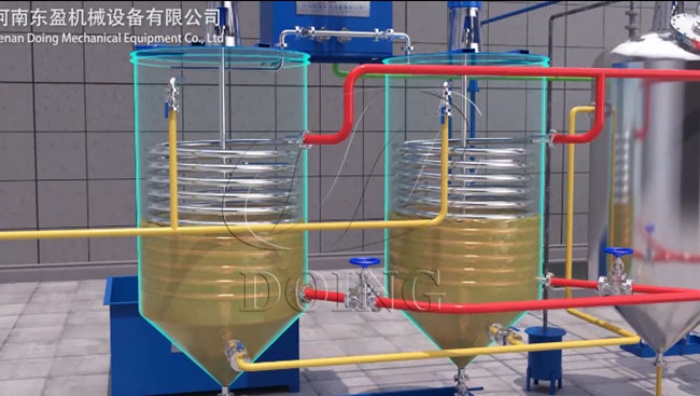

The sunflower oil refinery journey starts with degumming, where phospholipids and other colloidal impurities are removed. This step is crucial for ensuring sunflower oil clarity and extending shelf life. You can choose to use water degumming or acid degumming, depending on the properties of your sunflower oil.

Sunflower oil degumming and deacidification (neutralization) machine

Sunflower oil degumming and deacidification (neutralization) machine

2. Sunflower Oil Deacidification (Neutralization) Section

Because free fatty acids (FFAs) can quickly deteriorate, resulting in off-flavors and rancidity, degummed sunflower oil requires further deacidification. This process typically uses an alkaline solution to neutralize the FFAs and inhibit their increase. This effectively reduces the sunflower oil's acidity, improving flavor, stability, and safety.

3. Sunflower Oil Decolorization (Bleaching) Section

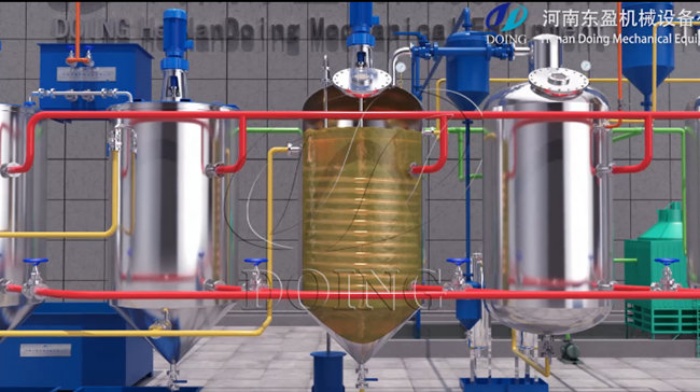

If you're looking for sunflower oil with a brilliant golden luster, you'll need to add a sunflower oil decolorization section. Here, you can choose to use a natural adsorbent, such as activated clay or activated carbon, to remove pigments and any remaining impurities. The bleached sunflower oil exhibits a clean, light and attractive golden appearance—a key factor in attracting consumers at the point of sale.

Sunflower oil decolorization (bleaching) machine

Sunflower oil decolorization (bleaching) machine

4. Sunflower Oil Deodorization Section

Deodorization, the final step in the sunflower oil refinery process, is central to controlling the sunflower oil's flavor and odor. Deodorization can remove odors and volatile compounds under high-temperature, vacuum conditions. The resulting sunflower oil has a mild, pure flavor and a high smoke point, making it ideal for a variety of culinary applications.

Sunflower oil deodorization machine

Sunflower oil deodorization machine

5. Sunflower Oil Dewaxing Section (Optional)

If you plan to bottle your sunflower oil or sell in cooler climates, this step is essential. Dewaxing removes natural waxes that can cause clouding or sedimentation when chilled. It guarantees your sunflower oil remains brilliantly clear, meeting the highest standards for premium bottled products.

Sunflower oil dewaxing machine

Sunflower oil dewaxing machine

6. Sunflower Oil Filtration & Packaging Line

Finally, the refined sunflower oil is filtered for polish and clarity, then transferred to the packaging line for bottling or bulk dispatch.

In conclusion, a modern sunflower oil refinery plant is highly automated, energy-efficient, and customizable to meet specific capacity and quality requirements. Ready to build or upgrade your sunflower oil refinery plant? Contact Henan Glory Company today. With a branch office and local warehouse in Nigeria, we can provide the expert support and parts supply you need.

PREV:Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

NEXT:What machines does a 10tpd crude cooking oil refining line include and how much is the price?

Leave a message

If you wanna to get more details about What are the components of sunflower oil refinery plant?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company