What machines does a 10tpd crude cooking oil refining line include and how much is the price?

In the edible oil processing industry, setting up a 10tpd (tons per day) crude cooking oil refining line requires a comprehensive understanding of the necessary machines and their prices. Using Henan Glory Company as an example, this article will guide you through the essential crude cooking oil refining machines of a 10tpd crude cooking oil refining line and provide insights into the price range, helping you make informed decisions for your business.

Machines Included in a 10TPD Crude Cooking Oil Refining Line

1. Cooking Oil Degumming Machine

(1) Function: Degumming machine can remove gums and phospholipids from the crude cooking oil. Gums can cause problems such as foaming during frying and reduced cooking oil stability. By removing these impurities, the cooking oil's quality and shelf - life are improved.

(2) Common Types: The most commonly used degumming method is acid refining. Generally, for a 10tpd crude cooking oil refining line, a separate degumming section is not set up. Instead, the degumming and deacidification purposes are completed in the same equipment as the alkali refining section.

Cooking oil degumming machine and deacidification machine

Cooking oil degumming machine and deacidification machine

2. Cooking Oil Deacidification Machine

(1) Function: Deacidification machine can reduce the free fatty acid content in the crude cooking oil. High levels of free fatty acids can lead to an unpleasant taste and odor in the cooking oil. Deacidification is crucial for producing high - quality edible oil.

(2) Common Types: The most common method is alkali refining, which uses caustic soda (NaOH) to react with free fatty acids, forming soapstock that can be separated from the cooking oil. The cooking oil deacidification equipment for this process usually includes a reaction tank, settlers and separation equipment.

3. Cooking Oil Decolorization Machine

(1) Function: Decolorization machine can remove pigments from the cooking oil, enhancing its visual appeal. Pigments can make the cooking oil look unappealing and may also indicate the presence of other impurities.

(2) Common Types: Activated clay or activated carbon is commonly used in the crude cooking oil decolorization process. The crude cooking oil decolorization equipment typically consists of a decolorization tank, where the cooking oil is mixed with the adsorbent material, and then a cooking oil filtration system to separate the oil from the used adsorbent.

Cooking oil decolorization machine

Cooking oil decolorization machine

4. Cooking Oil Deodorization Machine

(1) Function: Deodorization machine can eliminate volatile compounds, including unpleasant odors and flavors, from the cooking oil. This step is essential for producing edible oil that meets consumer expectations in terms of taste and smell.

(2) Common Types: Deodorization process is usually carried out under high - temperature and high - vacuum conditions. The crude cooking oil equipment includes a deodorization tower, heat exchangers and vacuum systems to ensure efficient removal of unwanted compounds.

Cooking oil deodorization tower

Cooking oil deodorization tower

5. Cooking Oil Filtration Machine

(1) Function: Filtration machine can remove solid particles and any remaining impurities from the cooking oil after each cooking oil refining step. Filtration process ensures that the final product is clear and free from contaminants.

(2) Common Types: Common Types: Vertical leaf filters play a key role in the crude oil refining process, particularly in the separation of adsorbents (clay/activated carbon) after decolorization. The three major advantages of efficient adsorbent interception, closed automatic slag discharge and significantly reduced residual oil rate directly guarantee the quality and economic benefits of refined oil.

Vertical leaf filter

Vertical leaf filter

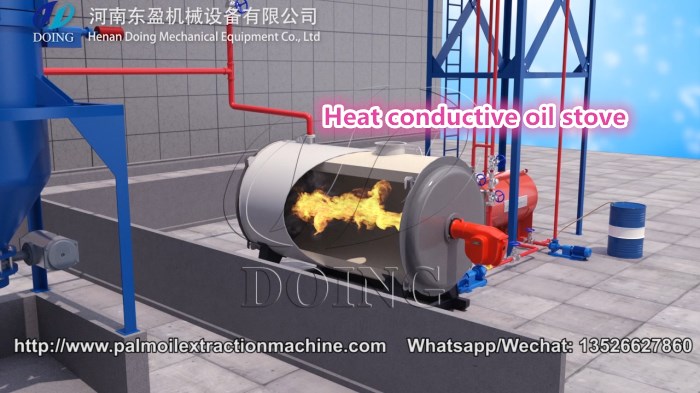

6. Heat Conducting Oil Furnace

(1) Function: Heat conducting oil furnace can supply heat for the 10tpd crude cooking oil refining line. Many of the refining steps, such as decolorization and deodorization, require specific temperatures to be maintained for efficient operation.

(2) Characteristics: A heat conducting oil furnace should be able to provide stable and adjustable heat output. It needs to be energy - efficient to reduce operating costs and comply with safety standards.

Heat Conducting Oil Furnace

Heat Conducting Oil Furnace

7. Steam Generator

(1) Function: Steam generator can produce steam, which is used in the cooking oil deodorization process. Steam helps to strip away volatile compounds from the oil under high - vacuum conditions.

(2) Characteristics: It should be able to generate high - quality steam with the appropriate pressure and flow rate to meet the demands of the cooking oil deodorization machine.

Price of a 10TPD Crude Cooking Oil Refining Line

The price of a 10tpd crude cooking oil refining line varies greatly, depending on the types of crude cooking oil refining machine.

1. Batch Type Crude Cooking Oil Refining Machine:

Generally, batch type crude cooking oil refining machine is the most affordable option. For a 10tpd crude cooking oil refining line, the price can range from $30,000 - $60,000. This type is suitable for small - scale producers with lower production requirements and limited budgets. However, it requires more manual labor as operations are carried out in batches.

Batch type crude cooking oil refining machine

Batch type crude cooking oil refining machine

2. Semi-Continuous Crude Cooking Oil Refining Machine:

Semi-continuous crude cooking oil refining machine is more expensive than batch type ones. The price for a 10tpd crude cooking oil refining line can be in the range of $60,000 - $120,000. They offer a balance between cost and production efficiency, with some automated processes in later refining stages like decolorization and deodorization.

Semi-continuous crude cooking oil refining machine

Semi-continuous crude cooking oil refining machine

In summary, investing in a 10tpd crude cooking oil refining line is a significant and potentially highly profitable investment. While the core crude cooking oil refining machines include degumming, deacidification, decolorization and deodorization machines, the final price is not predetermined. You should pay attention not only to the overall price, but also to the manufacturer's reputation, material quality, automation level and services such as installation, commissioning and training. If you have any needs in this regard, please contact Henan Glory Company (A manufacturer with more than ten years of experience in the production of crude cooking oil refining machines).

PREV:What are the components of sunflower oil refinery plant?

NEXT:Overview of soybean oil refining process and characteristics of refined soybean oil

Leave a message

If you wanna to get more details about What machines does a 10tpd crude cooking oil refining line include and how much is the price?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company