Overview of soybean oil refining process and characteristics of refined soybean oil

The soybean oil refining process involves several stages designed to remove impurities from crude soybean oil, improving its color, flavor, shelf life and suitability for consumption. Below is an overview of soybean oil refining process, followed by the characteristics of refined soybean oil.

Ⅰ. Overview of Soybean Oil Refining Process

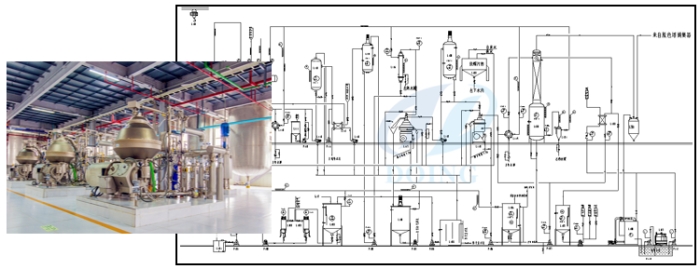

1. Degumming:

(1) Purpose: The primary goal is to remove phospholipids (gums) present in crude soybean oil. These gums can negatively affect the stability and quality of the soybean oil.

(2) Process: The crude soybean oil is treated with hot water or a dilute acid solution (such as phosphoric acid). The water helps hydrate the gums, which are then separated by centrifugation.

(3) Byproduct: The separated gums are collected and can be used for animal feed or further processed into lecithin, a food and industrial product.

Soybean oil degumming and deacidification equipment

Soybean oil degumming and deacidification equipment

2. Deacidification:

(1) Purpose: The main purpose of this stage is to inhibit the increase of free fatty acid (FFA) content in soybean oil. High levels of FFAs can lead to undesirable odors, lower the oil's stability, and reduce its culinary and industrial quality.

(2) Process: The soybean oil is treated with a dilute solution of caustic soda (sodium hydroxide). This reaction forms soapstock, which is then separated from the soybean oil.

(3) Byproduct: The soapstock, which contains fatty acids and other impurities, can be used in soap production or as an animal feed ingredient.

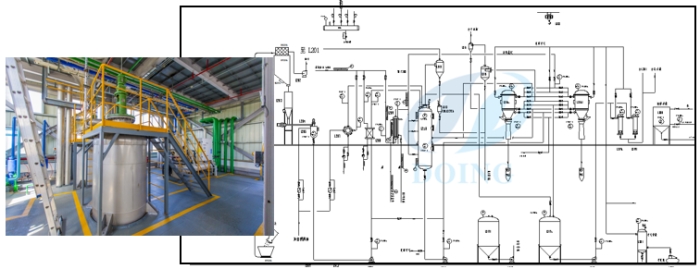

3. Decolorization:

(1) Purpose: The soybean oil decolorization process removes pigments (such as carotenoids and chlorophyll), oxidation products and trace contaminants, resulting in a lighter-colored soybean oil.

(2) Process: The soybean oil is mixed with adsorbents like bleaching earth or activated carbon, which absorb the pigments and impurities. After mixing, the adsorbents are filtered out, and the soybean oil becomes lighter in color.

(3) Byproduct: The bleaching earth is a byproduct that is usually discarded or recycled, but it can also be reused for various industrial applications.

Soybean oil decolorization equipment

Soybean oil decolorization equipment

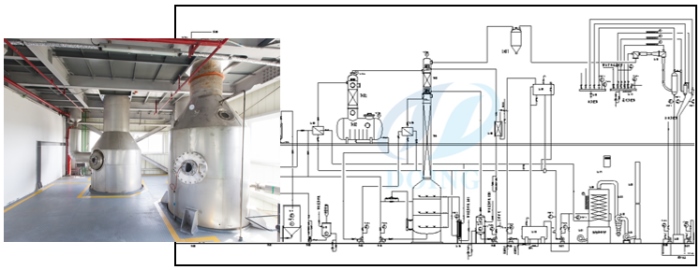

4. Deodorization:

(1) Purpose: This process removes volatile compounds that contribute to undesirable odors and tastes in the soybean oil, leaving a neutral oil with little to no smell or flavor.

(2) Process: The soybean oil is heated to high temperatures under a vacuum, and steam is introduced to remove the odor-causing compounds. This process also helps stabilize the soybean oil.

(3) Byproduct: The volatile compounds that are removed are collected and usually discarded or further processed.

Soybean oil deodorization equipment

Soybean oil deodorization equipment

Ⅱ. Characteristics of Refined Soybean Oil

After the soybean oil refining process, soybean oil becomes a high-quality product that is stable, neutral in flavor and versatile for cooking and industrial uses. Here are the key characteristics of refined soybean oil:

1. Color:

Appearance: Refined soybean oil has a pale yellow to light golden color. The soybean oil decolorization process removes dark pigments such as chlorophyll and carotenoids, resulting in a clear, attractive soybean oil.

Refined soybean oil

Refined soybean oil

2. Flavor and Odor:

Neutral Flavor: Refined soybean oil is neutral in flavor and odor after the soybean oil deodorization process. This makes it ideal for a wide range of culinary applications, as it does not interfere with the taste of the food being prepared.

3. Free Fatty Acids (FFA):

Low FFA Content: The soybean oil deacidification process reduces the level of free fatty acids to less than 0.05%, which helps improve the soybean oil’s quality, stability and shelf life.

4. Nutritional Composition:

(1) Polyunsaturated Fats: Refined soybean oil is rich in polyunsaturated fats, particularly omega-6 fatty acids (linoleic acid), which are essential for human health.

(2) Monounsaturated Fats: It also contains a moderate amount of monounsaturated fats, such as oleic acid.

(3) Saturated Fats: The oil contains a small amount of saturated fats (around 15-16%).

(4) Vitamins and Antioxidants: Refined soybean oil is a good source of vitamin E, a natural antioxidant that helps protect the oil from oxidation.

The above is a detailed description of the soybean oil refining process and the characteristics of refined soybean oil. Henan Glory Oils&Fats Engineering Co., Ltd. has been engaged in the edible oil processing industry for over ten years. If you are interested in developing soybean oil refining business, please contact Henan Glory. We can provide integrated equipment customized services based on your needs.

PREV:What machines does a 10tpd crude cooking oil refining line include and how much is the price?

NEXT:Why does crude palm oil need to be refined and what equipment is used in the refining process?

Leave a message

If you wanna to get more details about Overview of soybean oil refining process and characteristics of refined soybean oil, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company