Batch type edible oil refinery plant

Batch type edible oil refinery plant usually refers to 1-20tpd edible oil refinery plant, with lower cost, and easy to operation. Henan Doing Company is manufacturer and exporter of edible oil refinery plants in the China. All the batch type edible oil refinery plants are designed and supplied by us, so they have factory price and mature refining technology.

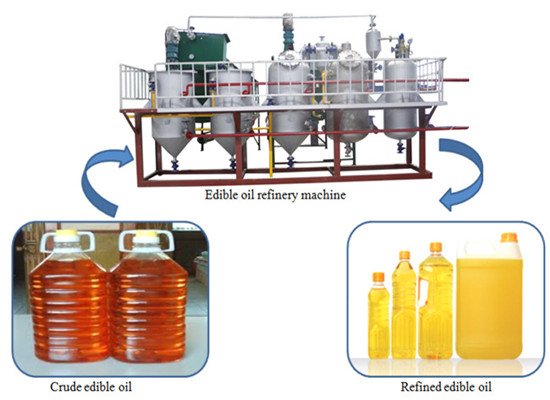

Edible oil refinery plant can make crude edible oil into refined edible oil

Edible oil refinery plant can make crude edible oil into refined edible oil

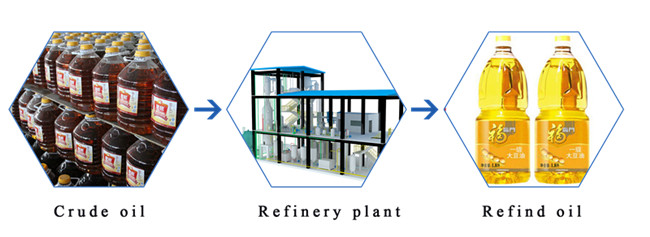

Batch type edible oil refinery plant is the most widely used in different kinds of small scale edible oil refinery factory. Such as soybean oil refinery plant, sunflower oil refinery plant, even palm oil refinery plant. Every year, there are lots of customers coming to buy the batch type edible oil refinery plant. Our engineers can design for you according to your demands. It can be designed into 1-20 tons per day, or up to 30 tons per day.

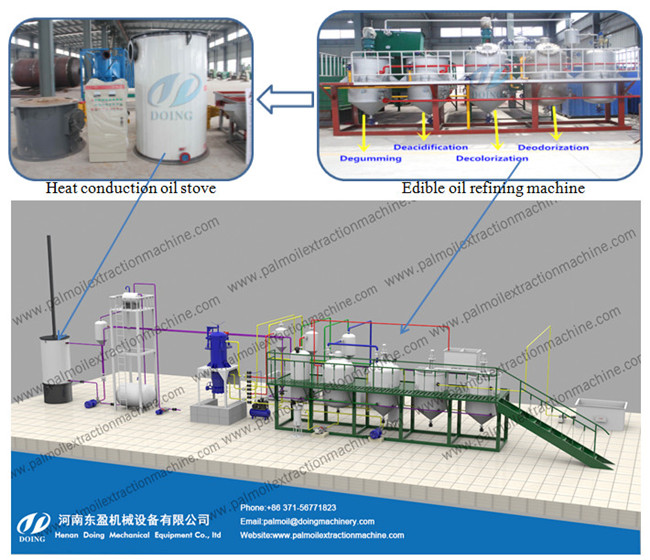

Batch type edible oil refinery plant designed by Henan Doing Company

Batch type edible oil refinery plant designed by Henan Doing Company

Batch type edible oil refinery plant uses chemical refining method, including degumming, neutralization, bleaching and deodorization process. But some oil need dewaxing or fractionation process, like sunflower oil, rice bran oil, palm oil. Generally speaking, edible oil refining is a process to remove unwanted and undesirable substances from the crude oil, including the Free Fatty Acid, Phospholipids, Gums, Odor, Pigments, Wax etc. It can make the vegetable oil clean and pure and improves the product oil quality.

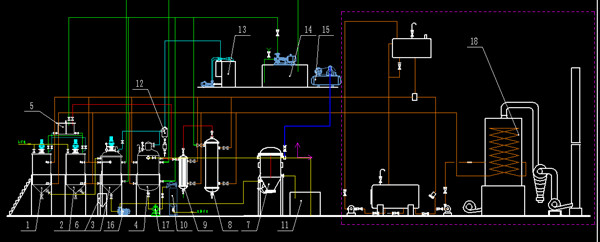

Batch type edible oil refinery plant flow chart designed by our engineers

Batch type edible oil refinery plant flow chart designed by our engineers

This is our engineers design a batch type edible oil refinery plant flow chart. Next, I will introduce the edible oil refinery process in details based on this flow chart.

Degumming and Neutralization Process of Batch Type Edible Oil Refinery Plant:

The crude oil is pumped to Neutralizer from oil mill or storage tank. Firstly, it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gum. And then, remove the Free Fatty Acids (FFA) by adding caustic soda. Thirdly, oil is heated up to about 60°C by heating coils and oil is stirred by the stirrer.

The chemical reaction between free fatty acid and caustic soda forms the soap stock. The soap stock can be separated from oil, and be used for making soap.

Bleaching Process of Batch Type Edible Oil Refinery Plant:

In the bleaching process, some pigments in the oil will be removed. Neutralized oil is heated in the bleacher vessel to remove excess moisture. And after it is treated with a measured quantity of bleaching earth and activated carbon. Next, oil passes through a filter to separate bleach earth and bleached oil. Oil obtained after bleaching process is light in color and has good golden type appearance.

Deodorization Process of Batch Type Edible Oil Refinery Plant:

The deodorization process removes odor from the oil to improve the quality and self-life of the oil. The clean bleached oil is heated in the deodorizer to remove all the bad smells, such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated in the deodorizer above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process is done under high vacuum.

Cooling Process of Batch Type Edible Oil Refinery Plant:

The deodorized oil needs to be cooled at the atmospheric temperature to avoid oxidation. The deodorized oil is cooled in the cooler vessel. The water circulating coils take away the heat and the oil is cooled.

Once the process cycle is complete the oil obtained will be RBD oil which is light in color. After cooling it will pass through polishing filter to obtain sparkling light color & odorless oil for packing, which will be used as final edible oil for cooking.

The dewaxing and fractionation process are mainly for some kind of oils. If your crude oil is sunflower oil, rice bran oil or palm oil, our sales and engineers will tell you the process you need.

All in all, batch type edible oil refinery plant is the best choice for customers who want to set up a small scale edible oil refinery plant. Leave the message, and we will provide the information you need.

Leave a message

If you wanna to get more details about Batch type edible oil refinery plant, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

-

Overview of soybean oil refining process and characteristics of refined soybean oil

Overview of soybean oil refining process and characteristics of refined soybean oil