1-10TPD small scale edible oil refining plant

In recent years, 1-10TPD small scale edible oil refining plant became more and more popular with investors. Almost every month there are customer come to visit our small scale edible oil refining plant model machine.

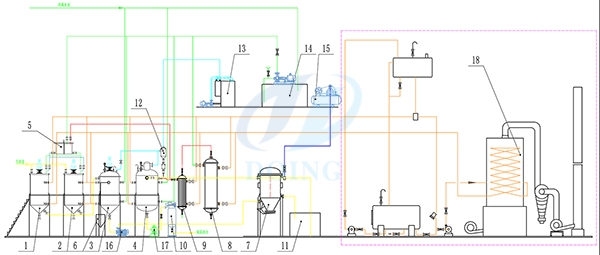

The main equipment in 1-10TPD small scale edible oil refining plant:

The flowchart of 1-10TPD small scale edible oil refining plant

The flowchart of 1-10TPD small scale edible oil refining plant

| 1 | Refining reactor A | 2 | Refining reactorB | 3 | Decolorization reactor |

| 4 | Deodorization reactor | 5 | Alkali liquor tank | 6 | White clay tank |

| 7 | Vibrate filter | 8 | Steam generator | 9 | Steam superheater |

| 10 | Precision filter | 11 | Decolorized oil tank | 12 | Oil foam catcher |

| 13 | Vacuum system | 14 | Water system | 15 | Air compressor |

| 16 | Decolorized oil pump | 17 | Product oil pump | 18 | Heat conductive oil system |

Note:

Heat conduction furnace: 1 set Offer enough thermo for the refining sections.

Steam generator: 1 set Produce steam for the workshop

Refining Pot: 2 sets Remove the gum, phosphoric acid etc

Decolorization Pot: 1 set Remove the color from neutralized oil

Deodorization Pot: 1 set Remove the solvent, smell, water from decolorized oil

Other Auxiliary Equipments: Alkali liquor tank, White clay tank, Air compressor, pumps, filters, Valves, Electricity Control Cabinet, etc.

1-10TPD small scale edible oil refining plant 3D model picture 1-10 TPD small scale edible oil refining process:

1-10TPD small scale edible oil refining plant 3D model picture 1-10 TPD small scale edible oil refining process:

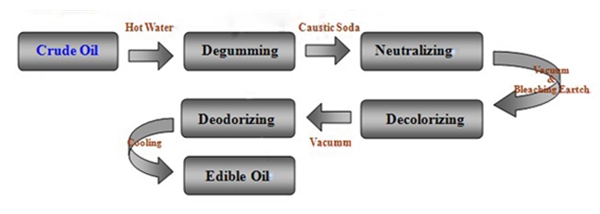

Small scale edible oil refining process flow chart

Small scale edible oil refining process flow chart

Note: welcome to watch cooking oil refining line process 3D video.

1. Degumming and deacidification:

The gumming is removed by phosphoric acid and hot water.

There are two ways to remove the acid in crude oil. One is chemical way, the other one is physical way. In 1-10TPD small scale edible oil refining plant, the chemical way is used. It mainly use NaOH to react with acid.

2.Decolorization:

The purpose of decolorization step in small scale edible oil refining plant is to remove color pigments contained in oils. It mainly use white soil adsorption decolorization methord.

3.Deodorization:

The function of this step is to remove disagreeable flavor and odors that are naturally present or created during processing under high temperature. Deodorization tank is a stainless steel sealed container, including heating coil and central steam jet circulating pipe.

1TPD small scale edible oil refining plant

1TPD small scale edible oil refining plant

The advantages of 1-10TPD small scale edible oil refining plant:

1. 1-10TPD small scale edible oil refining plant manufactured by Henan Doing company has won the national patent.

2. This small scale edible oil refining plant belongs to intermittent refining, low cost ,easy to transport, less operating personnel and energy conservation.

3. This small scale edible oil refining plant can be used to refine different kinds of crude cooking oil, such as soybean oil, groundnut oil, sunflower oil, cottonseed oil, plam oil, etc.

4. This small scale edible oil refining plant canproduce first-class refined edible oil to reach sanitation standard.

This is the whole introduction about 1-10TPD small scale edible oil refining plant. If you still have any questions, please contact us. Our engineer will explain to you in details.

PREV:Batch type edible oil refinery plant

NEXT:Nothing

Leave a message

If you wanna to get more details about 1-10TPD small scale edible oil refining plant, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Why Invest in Fully Automated Cooking Oil Refining Systems? Pros and Cons

Why Invest in Fully Automated Cooking Oil Refining Systems? Pros and Cons

-

How edible oil decolorization units enhance oil purity and shelf life?

How edible oil decolorization units enhance oil purity and shelf life?

-

Why activated clay is critical in edible oil decolorization process?

Why activated clay is critical in edible oil decolorization process?

-

Step-by-step maintenance plan for prolonging edible oil refinery system lifespan

Step-by-step maintenance plan for prolonging edible oil refinery system lifespan

-

Small edible oil refining equipment and principle

Small edible oil refining equipment and principle

-

Troubleshooting guide for agricultural edible oil degumming and deacidification equipment

Troubleshooting guide for agricultural edible oil degumming and deacidification equipment