Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Many groundnut oil producers face a common issue: crude pressed groundnut oil either turns turbid with precipitation or develops an off-odor after two months. In fact, the root of this problem lies in whether you use groundnut oil refining machine and your refined groundnut oil whether is qualified.

Next, Henan Glory will explain why refining machine is essential for oil quality, and in each refining step, what impurities are removed to make sure the quality of groundnut oil.

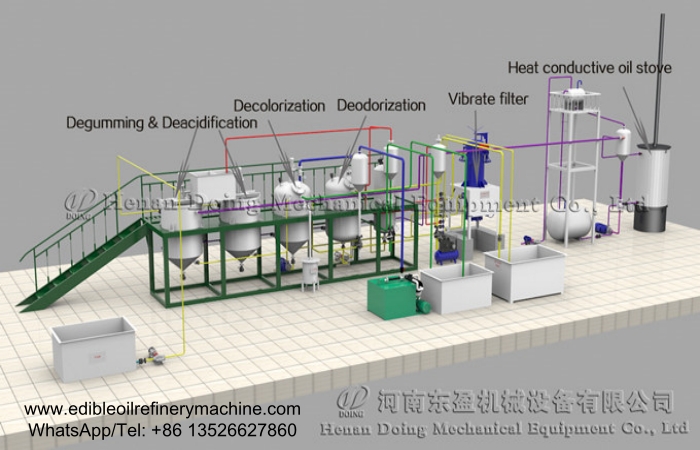

Batch groundnut oil refining machine

Batch groundnut oil refining machine

1. Degumming

Phospholipids in crude oil are the main cause of turbidity in groundnut oil. When crude pressed groundnut oil is stored for a while, precipitation forms—and customers are unwilling to buy such turbid oil.

Our degumming pot solves this problem as follows: Under stirring and heating, the crude oil is first heated to a specific temperature. A phosphoric acid solution is then sprayed into it to trigger a reaction, causing phospholipids and other colloids to coagulate completely. Once heating and stirring are stopped, the oil is left to settle for approximately 8 hours, allowing colloids to be discharged smoothly from the tank bottom. This process effectively removes the phospholipids that cause turbidity in the oil, improving its clarity.

2. Deacidification

Free fatty acids (FFA) impart an off-flavor to the oil and shorten its shelf life. This is why unrefined groundnut oil spoils quickly—cutting into your profits.

Our deacidification pot facilitates this process: After degumming, the oil is continuously stirred and heated until it reaches approximately 80°C. An alkaline solution (e.g., NaOH) is then sprayed into it to neutralize the oil. Once white flocs form, stirring is stopped and the oil is left to stand for separation. This separation allows soap stock to be removed, effectively eliminating FFA.

3. Decolorization

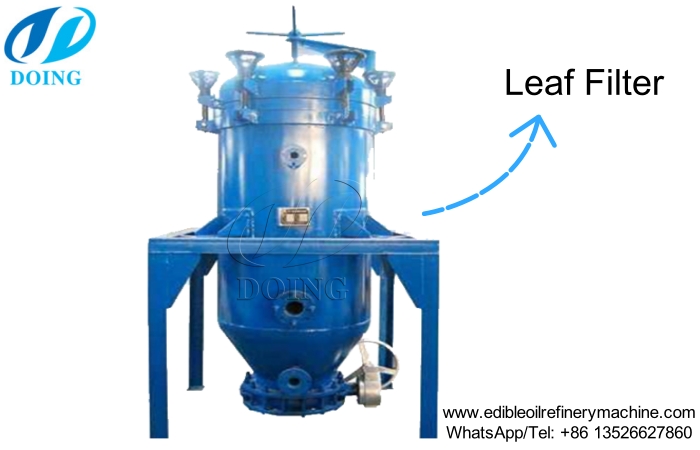

Crude pressed groundnut oil is often dark-colored, due to its natural carotenoid content and oxidized pigments generated during processing. However, the popular golden-yellow groundnut oil sold in supermarkets owes its color to decolorization machine. Our decolorization pot is fitted with a heating coil, which heats the deacidified oil while the oil is being stirred. It also automatically injects a fixed amount of activated clay, ensuring full contact between the oil and clay to effectively adsorb pigments. Once the decolorization reaction completes, the oil is pumped into a leaf filter.

Leaf filter

Leaf filter

4. Deodorization

Crude pressed groundnut oil may have a raw or burnt groundnut smell (caused by poor temperature control during pressing), but consumers prefer edible oil with no off-odors.

Our deodorization pot uses a water-jet vacuum pump to evacuate the pot in advance—before oil is introduced—to prevent the peanut oil from oxidizing at high temperatures. Once decolorized groundnut oil enters the pot, it is heated to a boil in a high-temperature vacuum environment, and volatile odor-causing compounds in the oil are extracted along with the steam.

The above-described batch refining machine from Henan Glory is suitable for groundnut oil refining plant with a daily processing capacity of under 20 tons. As your production grows, the machine can be upgraded to a semi-continuous system—for example, by adopting a continuous deodorization tower—increasing capacity to 30 tons per day with greater efficiency and cost-effectiveness. For large-scale groundnut oil refining plant exceeding 30 tons, we offer a fully continuous refining solution, featuring automated, continuous operation across all stages to maximize throughput and consistency.

Full-continuous groundnut oil refining machine

Full-continuous groundnut oil refining machine

If you are experiencing problems with turbid groundnut oil, short shelf life, poor appearance, or if you want to plan a new edible oil refining line, please contact Henan Glory.

PREV:Full Analysis of Batch Type Sunflower Oil Refining Equipment

NEXT:Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Leave a message

If you wanna to get more details about Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company