A:

The cost of the sunflower oil refinery plant is closely related to the sunflower oil refining machine, and the cost of the sunflower oil refining machine is determined by the processing capacity and the technology used.

A:

During the refining process of edible oil, crude oil will be lost. Oil loss is about 2-8%. But we can reduce the loss of edible oil through the following steps.

A:

For customers who want to start edible oil refining business, edible oil refining machines account for a large proportion of investment costs, so how to purchase edible oil refining machine to save costs?

A:

The red palm oil refining equipment can turn red palm oil into vegetable oil. To turn red palm oil into vegetable oil, there are 3 types of equipment to choose: batch refining equipment, semi-continuous refining equipment, full continuous refining equipme

A:

There are many advantage in investing in edible oil refinery plant, and investors can choose different refining types and equipment according to the conditions and refining capacity in different regions.

A:

The palm oil refining process has many advantages, such as extending the storage time of palm oil, benefiting health, earning more profits, etc.

A:

Henan Glory Company has do edible oil refining machine more than 12 years, let introduce the price to you according to the different type edible oil refining machine.

A:

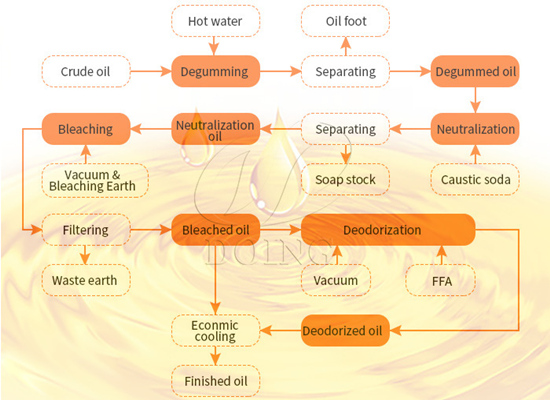

We usually remove impurities in crude oil through refining to obtain refined oil,1. Hydration degumming,2. Alkali refining deacidification,3. Adsorption decolorization,4. High temperature deodorization.

A:

Many friends from Tanzania plan to invest in small edible oil refinery plant. In order to pursue high-quality and cost-effective equipment, they choose to import from China.

A:

The small scale edible oil refinery plant usually use batch type edible oil refinery plant, including degumming and deacidification tanks and decolorization tank and deodorization tank.

A:

Edible oil refining is an important part of edible oil processing, but the following factors need to be considered when building an edible oil refinery plant to gain more profits.

A:

Both semi-continuous cooking oil refining machine and full continuous cooking oil refining machine can complete cooking oil refining process. Which type of cooking oil refining machine to choose specifically depends on the quality and production capacity

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.