What's the difference between sem-continuous cooking oil refining machine and fully continuous cooking oil refining machine?

About cooking oil refining machine We have semi-continuous cooking oil refining machine and full continuous cooking oil refining machine, both types of cooking oil refining machine can remove impurities contained in crude cooking oil obtained from presses or solvent extraction plants, and improve oil functions. So, what is the difference between sem-continuous cooking oil refining machine and fully continuous cooking oil refining machine? Henan Glory Company will answer for you.

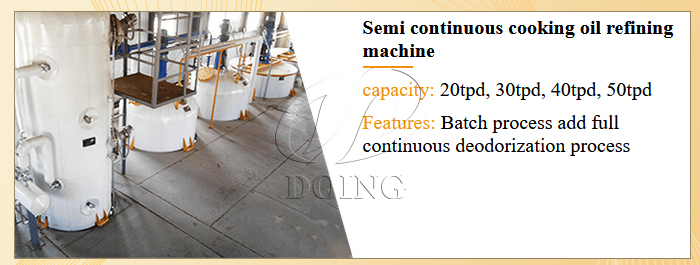

Actually, semi-continuous cooking oil refining machine is usually used in medium scale edible oil refinery plant(10-50tpd). In semi-continuous edible oil refinery plant, the deodorization pot is replaced by the deodorization tower. So the acid refining, alkali refining, bleaching process are all still batch type, but the deodorization process is automatic. If F.F.A. content of crude cooking oil more than 5%, and you don’t want to get large quantities of soapstock, semi-continuous cooking oil refining machine is the best choice.

Semi-continuous cooking oil refining machine picture

Semi-continuous cooking oil refining machine picture

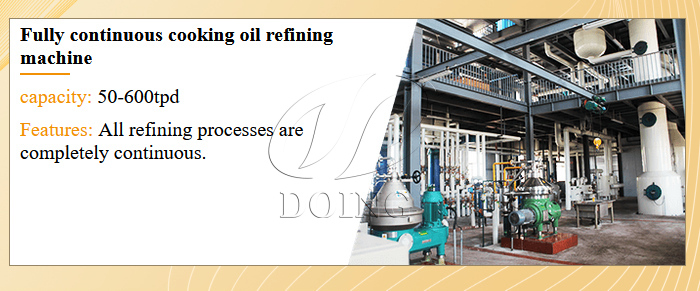

General speaking, for 30tpd and above, the full-continuous cooking oil refining machine is much better for large scale edible oil refinery plant. The fully continuous refining and deacidification section is equipped with a disc centrifuge to replace the natural sedimentation of soapstock, and each section is continuous production without interruption, however the cost of full-continuous cooking oil refining machine is high, the quality is much more steady and average. The whole cooking oil refining process is totally automatic. There are more equipment in full-continuous cooking oil refining machine, and the refining process is more complicated.

Full-continuous cooking oil refining machine

Full-continuous cooking oil refining machine

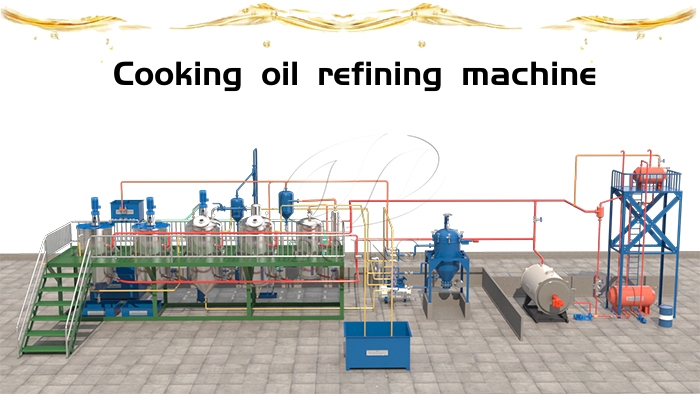

Crude cooking oil includes moisture, solids, gums, free-fatty acids (FFA), waxes, and compounds of sodium, potassium, magnesium, calcium, and other metals. All these impurities are removed in a series of steps: degumming (to remove gums), deacidification (to remove FFA), decolorization (to remove color), deodorization (to remove odor and taste), and dewaxing or winterization (to remove waxes),Both semi-continuous cooking oil refining machine and full continuous cooking oil refining machine can complete the above-mentioned refining process. Which type of cooking oil refining machine to choose specifically depends on the quality and production capacity of your crude cooking oil to design a suitable cooking oil refining machine for you.

Cooking oil refining machine produced by Henan Glory Company

Cooking oil refining machine produced by Henan Glory Company

In order to ensure human health, whether it is pressed cooking oil or solvent extraction cooking oil, it is best to be refined before eating. If you want to start cooking oil processing business, please contact us. Henan Glory Company provides you with cooking oil pressing machine and cooking oil solvent extraction machine, cooking oil refining machine and other cooking processing machine for your choice.

PREV:What factors need to be considered when building an edible oil refinery plant?

NEXT:What factors will affect the productivity of cooking oil refining machine?

Leave a message

If you wanna to get more details about What's the difference between sem-continuous cooking oil refining machine and fully continuous cooking oil refining machine?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company