What factors will affect the productivity of cooking oil refining machine?

The four stages of edible oil refining are degumming, deacidification, decolorization and deodorization. When using cooking oil refining machine, there are some factors that affect refining efficiency. Henan Glory will explain what factors affect refining efficiency.

1. Processing capacity

The processing capacity of cooking oil refining machine is one of the most important factors affecting its productivity. Cooking oil refining machine with higher throughput can process more oil in less time, increasing productivity.

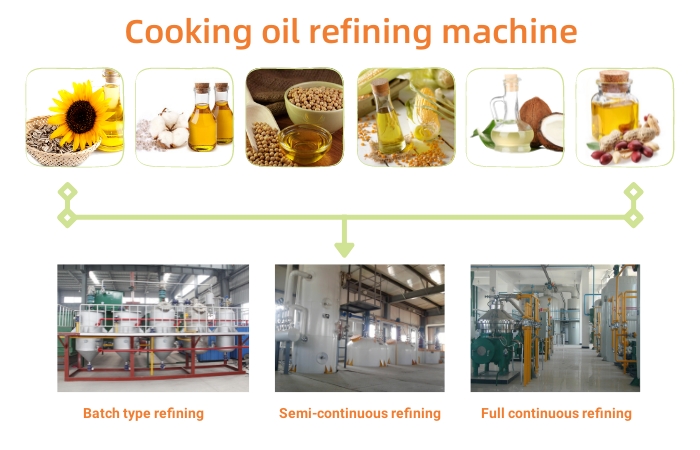

According to the size of the processing capacity, the cooking oil refining machine of Henan Glory Company can be divided into three types: batch type cooking oil refining machine, with a processing capacity of 1-20tpd; semi-continuous cooking oil refining machine, with a processing capacity of 10-50tpd; Continuous cooking oil refining machine with a processing capacity of 30-1000tpd.

Three types cooking oil refining machine

Three types cooking oil refining machine

2. Additive dosage

The amount of additives is another important factor affecting the productivity of cooking oil refining machine. During the deacidification process of cooking oil, the acid-base neutralization reaction is carried out by adding food-grade alkali. The amount and concentration of alkali affect the effect of deacidification, which further affects the productivity of cooking oil refining machine.

3. Operating conditions

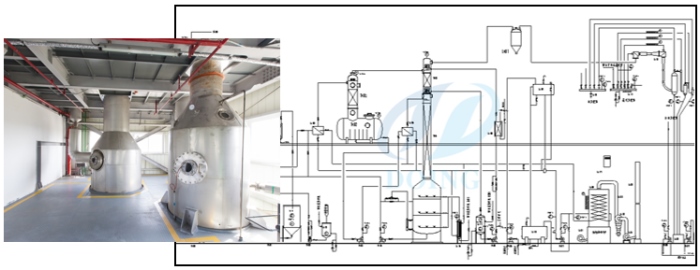

Temperature and humidity also have an impact on the productivity of cooking oil refining machine. Optimal operating conditions help maximize productivity. The decolorized oil is heated to high temperature (250-260℃), and then enters the deodorization tank. Under negative pressure, a small amount of superheated steam is passed into the cooking oil for a period of stripping, so as to achieve the purpose of deodorization. Reasonable control of deodorization temperature can improve the productivity of cooking oil refining machine.

Cooking oil deodorization process

Cooking oil deodorization process

4. Maintenance and repair

Regular maintenance and repairs of cooking oil refining machine are essential to ensure optimum performance and prevent downtime due to breakdowns or failures.

The above is an introduction to the factors that affect the productivity of cooking oil refining machine. To ensure maximum productivity and profitability, it is very important to consider these factors when selecting and operating cooking oil refining machine. If you want to know more about cooking oil production equipment, you can contact us at any time, we will provide you with the best service and professional advice.

Leave a message

If you wanna to get more details about What factors will affect the productivity of cooking oil refining machine?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company