Why is degumming the first step in edible oil refining?

Edible oil is an indispensable part of our daily diet. The process of edible oil refining mainly includes four steps: degumming, deacidification, decolorization and deodorization. Among them, the degumming process, as the first step in edible oil refining, plays a vital role. So, why is degumming the first step in edible oil refining? How does it ensure the quality and safety of the edible oil on our table? This article will answer your questions one by one.

1. Remove Phospholipids and Impurities from Edible Oil

After the initial extraction, edible oil usually contains some impurities, especially phospholipids. It is a natural substance in edible oil, with strong hydration and viscosity. During the edible oil extraction and storage process, it will bring enzymes, microorganisms and moisture into the edible oil, promoting oil hydrolysis and rancidity. If these impurities are not removed, the quality of the edible oil will not only be affected, but also may cause adverse phenomena such as precipitation and turbidity.

Edible oil degumming equipment and process combination diagram

Edible oil degumming equipment and process combination diagram

There are two common edible oil degumming processes: hydration degumming and acid refining degumming. Among them, hydration degumming refers to adding a certain amount of water to the edible oil, and using the affinity of water with colloidal substances such as phospholipids to separate them from the edible oil. Acid refining degumming refers to adding 85% or 75% food-grade phosphoric acid to the edible oil to remove the colloid-soluble impurities in the crude edible oil. In conclusion, these edible oil degumming processes can effectively remove insoluble impurities in edible oil, laying a good foundation for the subsequent edible oil refining process.

2. Improve the Antioxidant Properties of Edible Oil and Extend Its Shelf Life

In addition to removing impurities, edible oil degumming process significantly improves the edible oil's resistance to oxidation. If phospholipids and other substances in the oil are not removed, they will accelerate the oxidation of the edible oil, leading to a decline in edible oil quality and even the production of odors and harmful substances. By degumming process, we effectively remove these sources of oxidation, thereby greatly extending the shelf life of edible oils. This means consumers can enjoy fresh, healthy oil for longer, reducing waste and increasing the value of the edible oil.

3. Provide a Good Foundation for Subsequent Edible Oil Refining Processes

Edible oil degumming process is not only to remove impurities in the edible oil, but also lays a solid foundation for the subsequent edible oil refining processes. After removing the colloid impurities, the acid, pigment, and odorous substances in the edible oil can be removed more easily, which makes the subsequent deacidification, decolorization, deodorization and other processes more efficient. For example, the edible oil after degumming will be smoother in the deacidification process, and the acidic substances will be easier to remove, thereby improving the quality of edible oil and reducing its potential health risks.

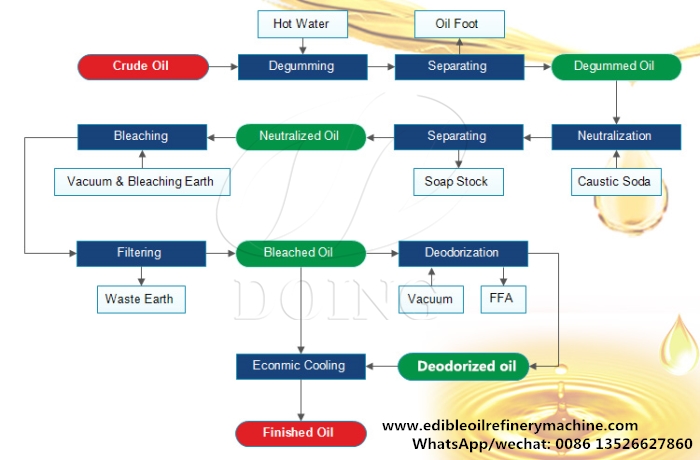

Complete edible oil refining process

Complete edible oil refining process

4. Improve the Color and Taste of Edible Oil

After degumming, the edible oil looks clearer and brighter, without precipitation and impurities, and looks more attractive. Moreover, after removing impurities, the taste of the edible oil is more delicate and pure. Especially in the production of high-end edible oil, the edible oil degumming process is even more important. It not only improves the color and taste of the edible oil, but also improves the overall quality, making the edible oil more competitive in the market.

5. Comply with Food Safety Standards and Protect Consumer Health

As people pay more and more attention to food safety, the quality requirements of edible oil are getting higher and higher. The edible oil degumming process is not only to improve the appearance and taste of edible oil, but also directly related to the safety of edible oil. By removing potentially harmful substances such as phospholipids, degumming can effectively reduce the risk factors in edible oil, ensure that the final product meets national food safety standards, and provide consumers with healthier and safer edible oil.

Henan Glory Company edible oil refining equipment

Henan Glory Company edible oil refining equipment

To sum up, as the first step in edible oil refining, degumming is a key process to ensure edible oil quality, improve edible oil stability and extend shelf life. By removing phospholipids and other impurities, the edible oil degumming process provides purer raw materials for subsequent edible oil refining steps, ensuring that the final edible oil can meet consumer demand in terms of taste, appearance, nutrition and safety. If you want to know more about edible oil degumming process or other edible oil refining process, please feel free to contact Henan Glory Company, we will serve you wholeheartedly!

PREV:Which oils need dewaxing treatment and what is the process?

NEXT:How much does it cost to build an oil refinery and how long does it take to build one?

Leave a message

If you wanna to get more details about Why is degumming the first step in edible oil refining?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company