A:

Vegetable oil refining plant can produce fatty acid, but it needs high-configuration vegetable oil physical refinery equipment. And if you want to get fatty acid with high use value, the fatty acid needs to be very pure.

A:

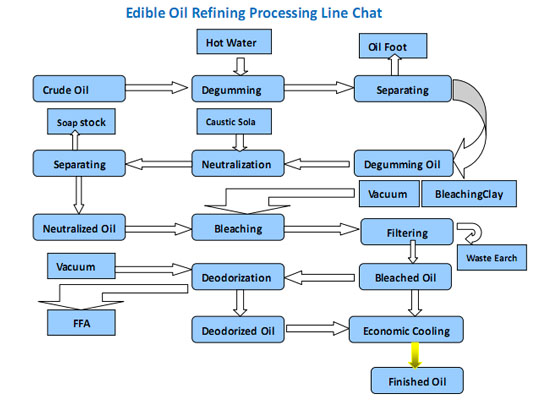

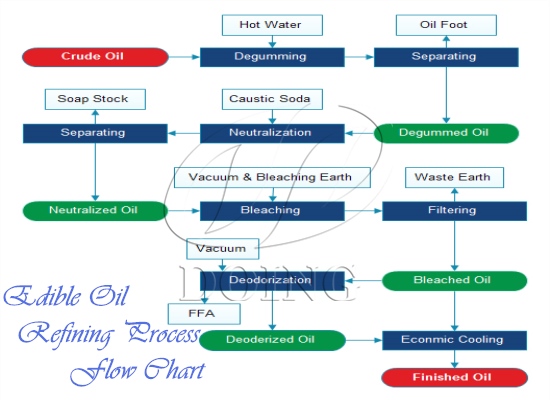

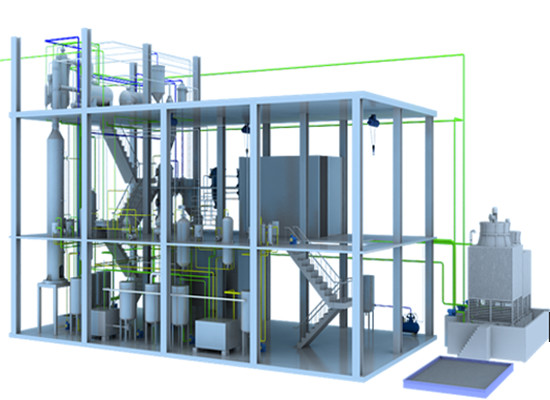

Refined edible oil is obtained through further processed by series of machines in edible oil refinery plant.Usually edible oil refining process includes degumming, deacidifaction, decolorization and deodorization four steps.

A:

Steam deodorization in edible oil refining process aims to remove undesirable smells in edible oil, so that it won’t influence product oil quality.

A:

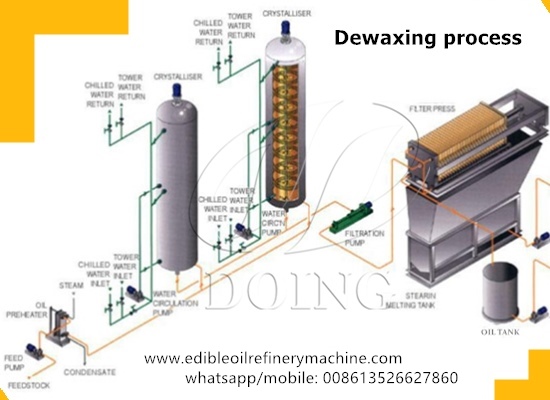

The wax content of crude sunflower oil is about 0.06-0.1%, whose exist will have bad effect on sunflower oil taste and transparency. Especially when cooking, high wax content sunflower oil produces smoke and strong smell.

A:

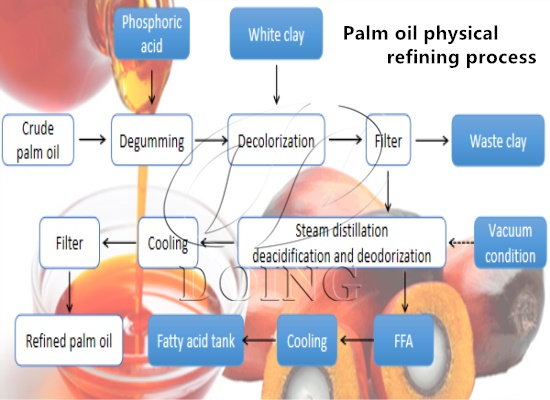

This continuous palm oil physical refining process flow chart is based on our engineers' designing palm oil physical refining technology, which is for 100tpd continuous palm oil refinery plant project in Kenya.

A:

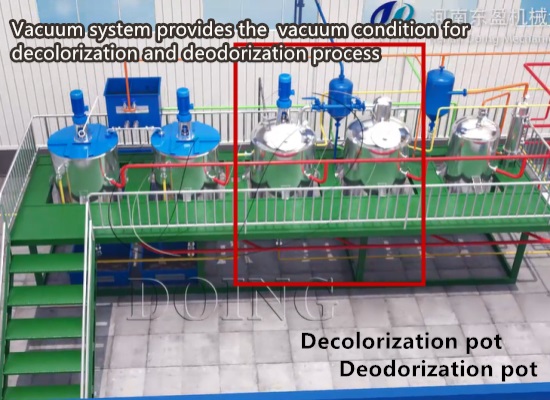

The function of vacuum system in edible oil refinery plant is to provide the vacuum condition for decolorization and deodorization process.The stability and reliability of vacuum system are the main factors to obtain high quality product oil.

A:

Edible oil refining process flow chart is usually designed by engineers according to customer's plant area and process requirements. Generally, edible oil refining process flow chart has three types based on the input capacity.

A:

Many people know that crude edible oil need to be refined, but why? The most important reason is that the cude edible oil can not fullfil the standard of nation. And crude edible oil can not sold in the supermarket.

A:

The quality of oil storage will directly affect the length of shelf life and production economic benefits of edible oil. The essence of oil storage technology is to solve the problem of oxidative stability of edible oils.

A:

In edible oil refinery plant, there are four kinds of cooking oil filter machine often used. They are plate and frame filter, leaf filter, vacuum diaphragm filter and safe filter. They have different functions.

A:

To be more specific, the palm kernel oil refinery includes degumming, deacidification, bleaching and deodorization four process. The following picture is DOING Company standard palm kernel oil refinery plant working principle with diagram.

A:

Generally speaking, impurities present in crude vegetable oil can be devided into four kinds: mechanical impurities, moisture impurities, colloidal impurity, fat-soluble impurities.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.