A:

Crude palm oil refinery plant is to further process the cpo to better quality RBD palm oil by removing the impurities. The most concern of many customer is how to improve the production yield in crude oil refinery plant.

A:

To refine crude oil into refined vegetable oil, you need buy the vegetable oil refining machine. As for the cheapest way, it is to buy a mini vegetable oil refining machine with capacity 1-2tpd.

A:

The biggest advantage of palm oil physical refinery technology is that in deacidification process, free fatty acid are taken away by high temperature steams in the vacuum deodourization tank instead of neutralization reaction.

A:

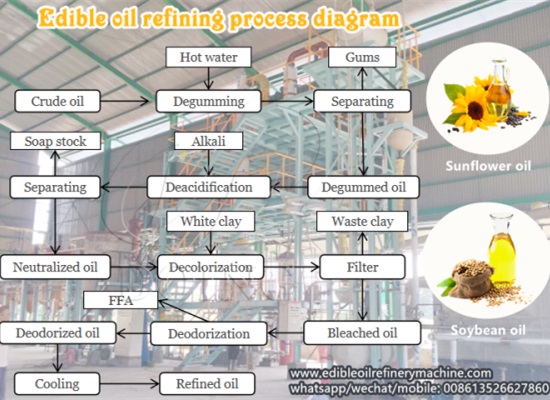

To refine red palm oil, there are four steps to do: degumming, deacidification, decolorization and deodorization. These four steps of palm oil refining processes are to remove the gum, deep color, odor and FFA.

A:

Palm oil purification process used in palm oil refinery plant refers to palm oil refining process. Usually, there are two kinds: palm oil physical refining process and palm oil chemical refining process.

A:

The requirement of temperature in every step of edible oil refining process is very strict. Because different steps have different functions, generally, the temperature of every step is decided by engineers when designing. Next, I will explain.

A:

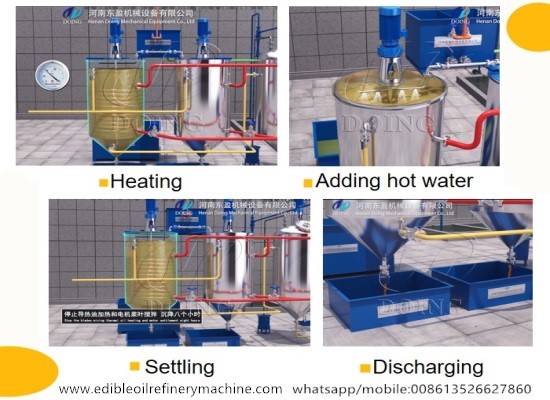

Because water degumming method is suitable for crude oil which contains much gums, in soybean oil refining process, engineers generally recommend to choose water degumming method to remove gums in soybean oil, so as to reach best degumming effect.

A:

Bleaching earth is used to absorb pigment and color in the crude oil. But how much bleaching earth to charge in edible oil refining process? In fact, the amount of bleaching earth to use is influenced by some factors.

A:

There are two ways to remove the gum in crude vegetable oil in vegetable oil refining process. One is hydration degumming way, the other is dry degumming way. These two ways are suitable for different crude vegetable oil.

A:

Our edible oil refining process diagram can show you clear of each steps in the edible oil refining plant, and what kind of final oil you can get after refining. But different kinds of crude oil may need different refining process diagrams.

A:

Edible oil refinery plant is mainly to process crude vegetable oil into refined edible oil. But do you know how a crude edible oil refinery plant works? A crude edible oil refinery plant has five steps to refine the crude vegetable oil.

A:

RBD palm oil and RBD palm olein belong to different products of palm oil.RBD palm oil is the products of palm oil refinery plant. And RBD palm olein is obtained after further processing RBD palm oil in palm oil fractionation plant.

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.