What is the requirement of temperature in edible oil refining process?

The requirement of temperature in every step of edible oil refining process is very strict. Because different steps have different functions, generally, the temperature of every step is decided by engineers when designing. In a whole, the requirement of temperature in edible oil refining process is not less than 60 degree.

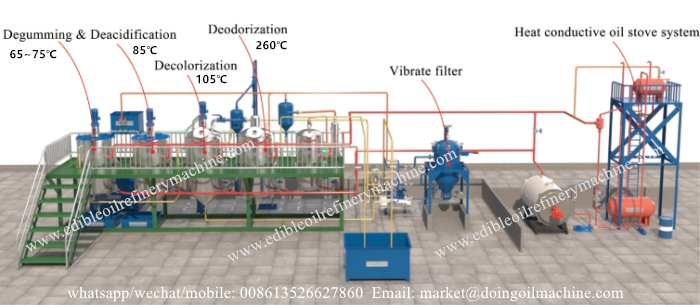

I guess you have known that all the edible oil refining process contains four steps: degumming, deacidification, decolorization and deodorization. Next, I will explain the requirement of temperature in every step.

The requirement of temperature in every step of edible oil refining process

The requirement of temperature in every step of edible oil refining process

At first, you should know that all the edible oil refining process is heated by heat conductive oil. Before refining process starting, the heat conductive oil need to be increased to 85℃ firstly, and then is used in degumming step.

In degumming step, before adding water, the temperature of the crude oil need to be increased into 65~75℃, and then by hydration reaction, remove gums.

In deacidification step, the temperature of the degummed oil need to be increased to 85℃, and the add NaOH solution to mix with FFA, so as to remove “acid impurites”.

In decolorization step, adopting different type decolorizer, the requirement of temperature is different. Usually, Doing Company engineers recommend to using white clay as decolorizer. So in this step, the deacidification oil needs to be increased to 105℃.

In deodorization step, usually use high temperature steam about 260℃ to remove odors. Of course, if you want to use shorter time, it can use higher temperature. As experiment shows, in the range of deodorization temperature, increasing of every 17℃, dedorization period will reduce half. But more remarkable, if the temperature is over high, it will produce harmful substances, so you should make sure with engineers.

Besides, some crude oil needs other refining steps. For example, sunflower oil need dewaxing process and palm oil need fractionation process. (Related reading: Why sunflower oil need dewaxing?and Palm oil dry fractionation process) The requirements of temperature are also different. All in all, the temperature is a very important factor to control refining effect. If you want to set up an edible oil refinery plant, please no hesitate contact us. Doing Company engineers will supply you professional technology support, and because we are manufacturer, can provide you factory price.

PREV:What kind of palm oil purification process is used in palm oil refinery plant?

NEXT:Why to choose water degumming method in soybean oil refining process?

Leave a message

If you wanna to get more details about What is the requirement of temperature in edible oil refining process?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company