Palm oil dry fractionation, solvent fractionation, surfactant fractionation technology process analysis and flow chart

The current palm oil fractionation technology can be divided into: dry fractionation of palm oil, solvent fractionation of palm oil and surfactant fractionation of palm oil. This paper comprehensively analyzes the principles and processing conditions of these three technologies. Focus on the palm oil fractionation process commonly used in Henan Doing Company - palm oil dry fractionation technology and equipment.

Palm oil is one of the most successful oils developed in recent decades. It has excellent properties and has more advantages than other oils in technology and economy. Saturated fatty acids and unsaturated fatty acids account for about 50% of palm oil, giving palm oil better oxidation stability than other vegetable oils. The effective way to make rational use of palm oil is palm oil fractionation process, which can make all kinds of palm oil products.

What is palm oil fractionation?

Palm oil fractionation process can get palm olein and stearin

Palm oil fractionation process can get palm olein and stearin

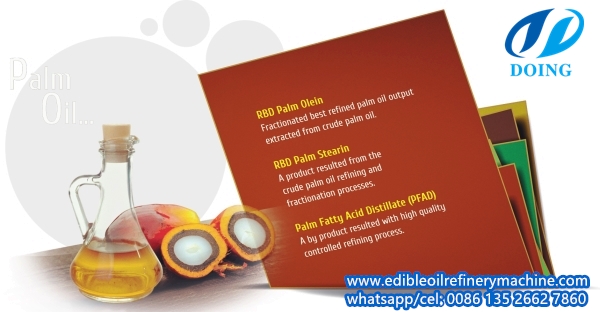

Palm oil fractionation technology refers to the separation of palm oil into low melting point liquid phase (olein) and high melting point solid phase (stearin) by controlling the cooling crystallization process of palm oil. Through palm oil fractionation process, palm oil can be separated into three components: palm stearin, palm olein and palm midfraction. The palm stearin melting point is generally 50℃, and the palm olein is generally about 24℃. The palm stearin is suitable for making margarine and shortening without causing slow crystallization, greasy feeling and post-hardening, and greatly improving the plastic range of fats. The palm olein is an excellent frying oil.

Palm oil fractionation method:

Palm oil fractionation technology commonly has three methods: dry fractionation, solvent mention and surfactant fractionation. The application of these three methods mainly depends on the physical and chemical properties of the desired palm olein and palm stearin. By changing the methods and conditions of fractionation, palm stearin with different physical properties and chemical properties can be obtained. At the same time, you can also get the palm olein with a very small change in physical and chemical properties.

Dry fractionation of palm oil fractionation technology:

Dry fractionation of palm oil fractionation technology is the main palm oil fractionation process used in Henan Doing palm oil fractionation plant, and is also one of the most economical methods, which means that the oil in a dissolved state is slowly cooled to a certain extent without adding any solvent, and then filtered to separate palm olein and stearin.

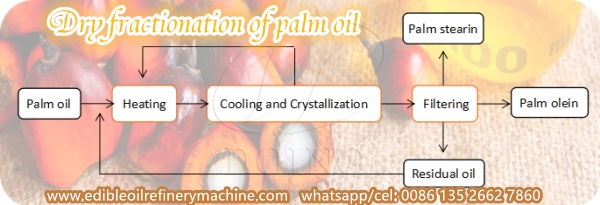

The dry fractionation process mainly consists of three steps. The first step is heating to break the crystal in palm oil. The second step is the crystallization in which solid crystals are produced in a liquid matrix by a cooling process. The third step is a filtration process where the liquid phase is separated from the crystals. In the crystallization stage, the oil is melted in order to destroy the memory effect before it is cooled in crystallizer chamber. The presence of crystal memory can negatively affect the yield and process repeatability.

Dry fractionation process of palm oil fractionation flow chart

Dry fractionation process of palm oil fractionation flow chart

1. Heating

Palm oil is semi-solid at normal atmospheric temperature. Its saturated acid and unsaturated acid account for about 50%. The unique composition of palm oil determines that palm oil need special crystallization process. Palm oil is dissolved into a liquid state by heating before processing, and is generally heated to about 70 degrees Celsius before crystallization to break all existing crystals.

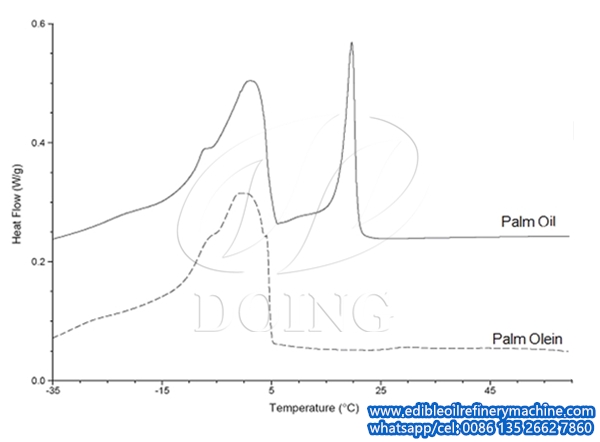

2. Cooling and Crystallization

The key to dry fractionation technology of palm oil is cooling and crystallization. If crystallization is successful, to separe palm olein and stearin is easy.

Palm oil crystallization process changing trend

Palm oil crystallization process changing trend

The specific operation is to control the cooling process by setting the temperature difference between the oil and the cooling water and the cooling time under stirring and circulating water cooling, then form a crystal nucleus and grow up slowly. When the desired temperature is reached (depending on the quality of the desired palm olein, usually 20℃), stop cooling.

3. Filtration

Controlling cooling and crystallization conditions is important, but the selection of filtration equipment has a great influence on the yield of liquid oil. In recent decades, membrane filters have been widely applied. Compared with continuous belt vacuum filter and drum filter, membrane filter has higher yield of palm olein (70%-75%) and higher hardness of palm stearin, while the yield of palm olein separated by other two filters is only 65%. The palm oil fractionation plant manufactured by Doing Company is exactly using membrane filter.

Solvent fractionation of palm oil fractionation technology:

Solvent fractionation process refers to the oil in proportion to add a certain solvent to form a mixed oil system, and then cooling crystallization, extraction of a separation method. Palm oil solvent fractionation process can form stable crystals which are easy to filter, improve separation efficiency, increase separation yield, shorten separation time and improve the purity of separation products. It is especially suitable for the fractionation of fatty acids with long carbon chain and high viscosity in a certain range.

The specific method is to let the palm oil dissolve in the solvent, and then cool to the appropriate temperature, then get a more ideal crystal. If the required temperature is very low, the brine is cooled. Mixed oils containing palm oil crystals and solvents are absorbed into a drum filter and separated by vacuum filtration from the palm olein and palm stearin. The solvent is then distilled to achieve separation. The yield of palm olein is generally up to 80%.

The efficiency of solvent fractionation process is high, and the quality of solid lipid components is good. However, due to the low crystallization temperature and solvent wastage involved in the fractionation process, its investment is large and the production cost is high. So solvent fractionation is only used to produce high value-added products. A typical example is the fractionation of palm tung oil to obtain intermediate components used as cocoa butter-like raw materials.

The products got from palm oil fractionation plant

The products got from palm oil fractionation plant

Surfactant fractionation of palm oil fractionation technology:

Surfactant fractionation process refers to the method of adding surfactant to improve the interfacial tension between oil and fat after cooling and crystallizing, and forming the suspension of fat in the aqueous solution of surfactant by the affinity between fat and surfactant to promote the segregation of lipid crystals. The process of surfactant fractionation includes cooling crystallization, surfactant wetting, centrifugal separation and surfactant recovery.

The surfactant fractionation technology has high separation efficiency, good product quality and wide application, and is suitable for mass production. However, the cost of surfactant process is high and the product is unsatisfactory because of surfactant contamination. In some countries, surfactant process is prohibited for vegetable oil production.

To sum up, in the three palm oil fractionation process, the application of dry method is more promising. It has the advantages of simple process, high degree of automation control, low steam consumption, good product quality, no need for centrifugal separator, no solvent, no waste water. So Henan Doing Company palm oil dry fractionation plant is your best choice. We can provide 5-10tpd small scale palm oil fractionation plant and 50-600tpd large scale palm oil fractionation plant. Welcome to contact us!

PREV:What is refined vegetable oil? How to make refined vegetable oil?

NEXT:How much does it cost to build an edible oil refinery plant?

Leave a message

If you wanna to get more details about Palm oil dry fractionation, solvent fractionation, surfactant fractionation technology process analysis and flow chart, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

-

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company