A:

The main product obtained from crude palm oil refining is refined palm oil, also called RBD palm oil.And there will be some by-products which can be sold or be further process,such as soap stock or pure free fatty acid.

A:

Generally, the temperature of different process while refining vegetable oil are different, and the requirement is very strict. They are decided by engineers when designing the vegetable oil refining process.

A:

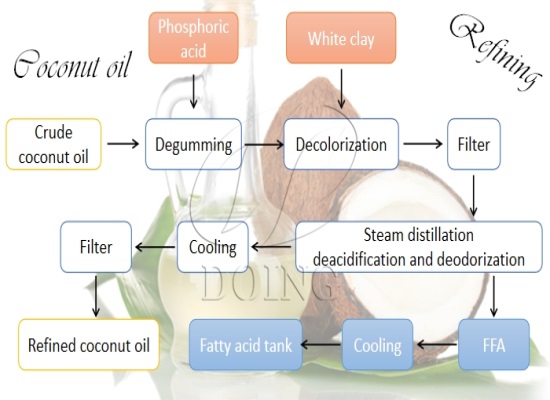

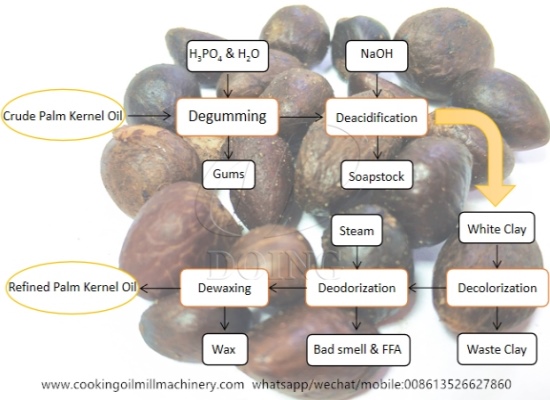

In vegetable oil refining industry, adding phosphoric acid or hot water is to remove the gums from crude oil, which is called degumming process.Adding phosphoric acid has better degumming effect than using hot water.

A:

The alkali refining of palm oil is one kind of palm oil deacidification method. It is called chemical refining method, usually used in batch type and semi-continous palm oil refinery plant.

A:

Small scale vegetable oil refinery plant is a batch type crude oil refining production line which remains all the functions of medium and large scale vegetable oil refinery plant. In addition, it needs small investment cost and less land occupation.

A:

How is coconut oil refined in vegetable oil refinery? It is usually used to get raw materials to make soap through chemical refining method. However, if you want to get high quality RBD coconut oil, physical refining technology is better.

A:

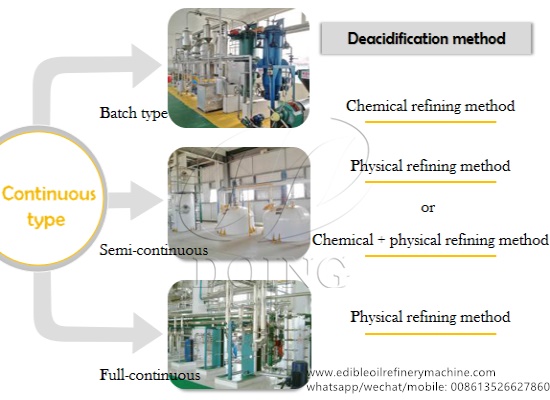

By continuous type, there are three types of refining method in edible oil refining process: batch type, semi-continuous and full-continuous edible oil refining method. And by the deacidification method, there are chemical refining method and physical

A:

Usually, in palm kernel oil refining plant, there are four steps to refine palm kernel oil: degumming, deacidification, decolorization and deodorization. Only all the steps are qualified, you can get high quality refined palm kernel oil.

A:

In cooking oil refining process, there is a special process that is used to get rid of odors in crude oil, which is deodorization process. The deodorization is using high temperature steam to take the odors off.

A:

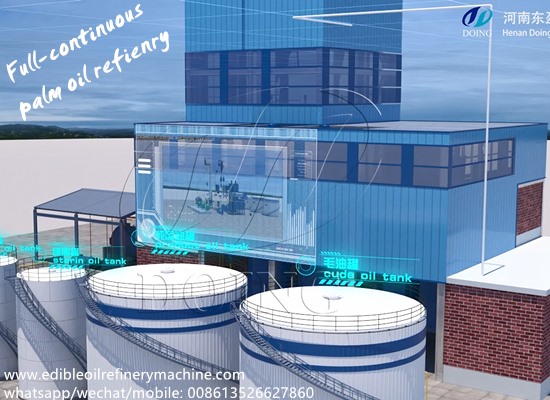

Full-continuous palm oil refinery plant generally uses dry degumming technology and physical refining technology. And it is divided into seven sections.Then, how dose the full-continuous palm oil refinery plant work?

A:

The neutralization process of edible oil is a part of whole edible oil refinery process, which is also called the deacidification process of edible oil. But it belongs to chemical deacidification method, using alkali to react with FFA, and then get so

A:

In the refining process of edible oil, three kinds of chemicals will be usually used. They are phosphoric acid, alkali, white clay. Do you know what functions they have?

contact us

edible oil refinery products

edible oil refinery plant projects

edible oil refinery plant solutions

News

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

Leave a message

If you wanna to get more details about edible oil refining method and technology information in vegetable oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.