How does small scale vegetable oil refinery plant work?

Small scale vegetable oil refinery plant is a batch type crude oil refining production line which remains all the functions of medium and large scale vegetable oil refinery plant. In addition, it needs small investment cost and less land occupation. That means your investment can get quick return, which makes the small scale vegetable oil refinery plant is especially ideal for who want to start vegetable oil refinery plant with small budget.

How does small scale vegetable oil refinery plant work? The following video shows the detailed refining process of small scale vegetable oil refinery plant.

The main four working processes of small scale vegetable oil refining plant:

1. Degumming:

The degumming process used in small scale vegetable oil refinery plant is to remove gelatinous impurities within crude oils by chemical methods. Based on the principle that phospholipid and some proteins within the crude oils are soluble to oils, but insoluble in oil and water after the formation of hydrate, the degumming process is to heat crude oils firstly, and then to add hot water or steam into crude oils, to agitation mix and settle. Then separate out the phospholipids and part of the proteins from the crude oils.

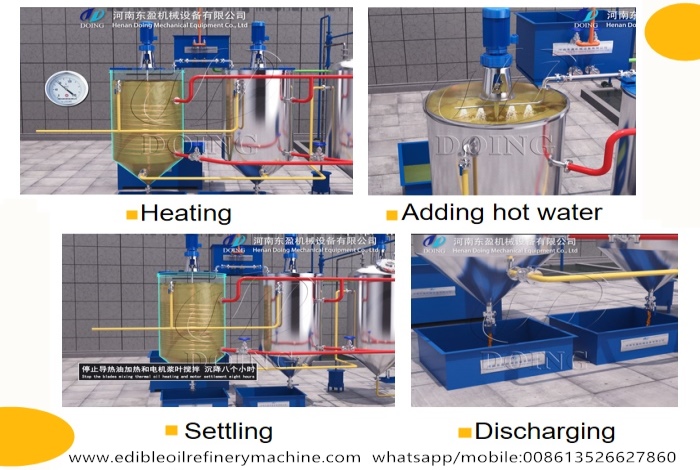

Degumming process operation steps

Degumming process operation steps

Why need degumming? If the content of phosphatide in vegetable oil is high, it is easy to blister, smoke and smell when heated. And the phospholipid is oxidized at high temperature and then make the crude oils in dark brown, which affects the flavor of fried food.

2. Deacidification:

The deacidification process used in small scale vegetable oil refinery plant is to remove Free Fatty Acid (FFA) is by alkali refining. Based on the principle of acid-base neutralization, heat crude oils firstly, and then add alkali liquor, to agitation mix and settle. Then separate out the soap stock from crude oils.

Why need deacidification? The FFA contained in the crude oils will affect its stability and flavors. And too much FFA content will make the vegetable oil unqualified.

3. Decolorization:

The decolorization process used in small scale vegetable oil refinery plant is same as that used in large scale vegetable oil refinery plant. It is use the adsorption effect of white clay to remove the pigments from the crude oils.

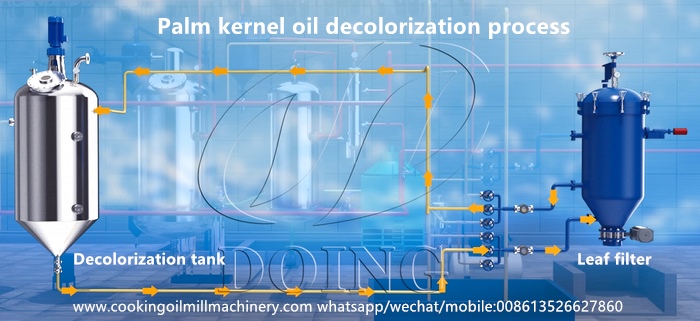

The equipment used in decolorization process

The equipment used in decolorization process

Why need decolorization? The crude oils may contain chlorophyll, carotenoid and other pigments. Chlorophyll is photosensitizer, which affects the stability of oil, while other pigments can affect the appearance of oil.

4. Deodorization:

The deodorization process used in small scale vegetable oil refinery plant is also same as that used in large scale vegetable oil refinery plant. It adopts vacuum distillation method to remove odors out from crude oils.

Why need deodorization? There are some undesirable odor substances in crude oils, mainly from oil oxidation products, which will affect the quality of vegetable oil. So before deodorization, the deodorizing tank needs to be vacuumized, to prevent the oil from oxidizing again at high temperatures.

The features of DOING small scale vegetable oil refinery plant:

DOING small scale vegetable oil refinery plant

DOING small scale vegetable oil refinery plant

1. Small investment and quick returns.

2. Low energy consumption and small footprint.

3. Compact structure and beautiful layout.

4. Simple structure and easy operation.

5. Obtain high quality refined oil that can be used for edible or industrial use.

The small scale vegetable oil refinery plant can process many different kinds of crude vegetable oils, including sunflower oil, groundnut oil, soybean oil, olive oil, palm oil, palm kernel oil, mustard oil, canola oil, etc. If you plan to buy small scale vegetable oil refinery plant, please contact us for detailed specifications and latest prices!

PREV:What is alkali refining of palm oil?

NEXT:How is the refined coconut oil made in vegetable oil refinery?

Leave a message

If you wanna to get more details about How does small scale vegetable oil refinery plant work?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company