How many types of refining method are there in edible oil refining process?

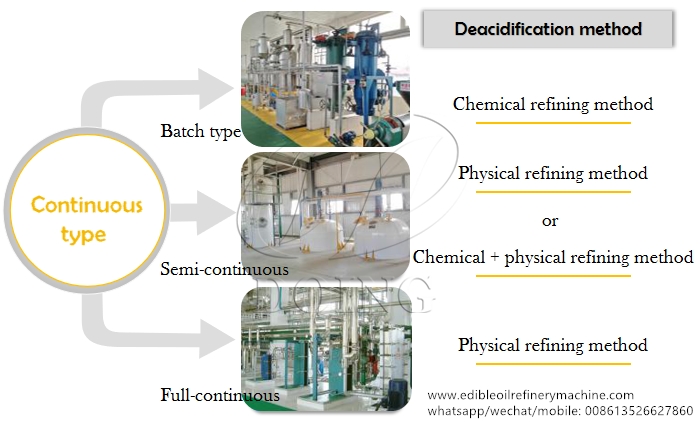

By continuous type, there are three types of refining method in edible oil refining process. They are respectively batch type, semi-continuous and full-continuous edible oil refining method. And according to the deacidification method type, there are two types of refining method in edible oil refining process: chemical refining method and physical refining method. So when the customers plan to set up an edible oil refinery plant, to choose suitable edible oil refining method is very important. Then, how to choose?

Different types of refining method in edible oil refining process

Different types of refining method in edible oil refining process

Let us firstly learn about the four steps in edible oil refining process: degumming, deacidification, decolorization and deodorization. The function of the four process is to remove and reduce gums, FFA, pigments and bad odors from crude oil, and finally improve oil storage stability, flavor and color, then get standard quality edible oil.

According to the first classification, whatever which type of edible oil refinery plant you choose, the four steps are necessary, so the similarities of the three oil refinery plant is to have the same function which is to make the final oil reach edible oil standard. Besides the similarities, you must know their difference, which decide which type oil refinery plant you should choose.

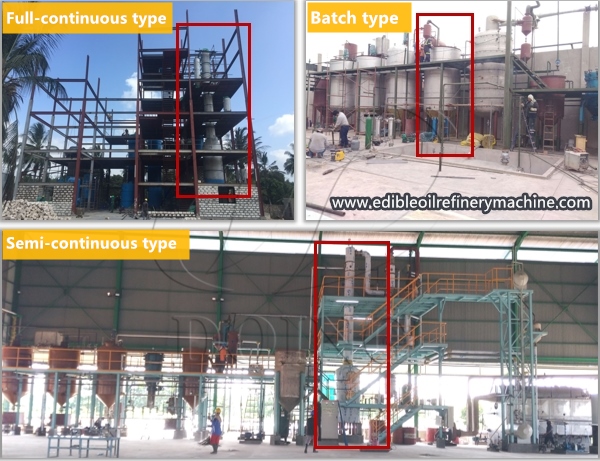

The machine’s configurations are different in different types of edible oil refinery plant

The machine’s configurations are different in different types of edible oil refinery plant

At first, the machine’s configurations are different. The batch type edible oil refinery plant uses four tank for each step: they are degumming tank, deacidification tank, deodorization and deodorization tank. While semi-continuous type edible oil refinery plant uses deodorization tower to replace deodorization tank, and full-continuous type edible oil refinery plant uses decolorization tower and deodorization tower to replace tanks, and other machines configurations are also different.

Secondly, the degree of automation is different. The process of batch type edible oil refinery plant is batch by batch. Compared with batch type, the deodorization process of semi-continuous edible oil refinery plant is continuous. And the whole process of full-continuous edible oil refinery plant is continuous.

Next, you also need to choose suitable edible oil refining method according to crude oil kind and finished oil requirement, capacity, and budget.

At first, capacity is a standard for choose the edible oil refinery plant type. The batch type is often suitable for 1-10T/D small scale capacity. Semi-continuous type is suitable for medium scale capacity with 20-50T/D, and above 50t/d capacity often uses full continuous type.

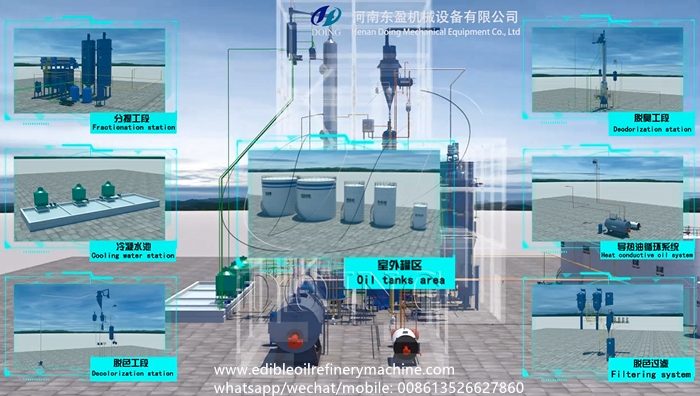

The full-continuous physical refining method edible oil refinery plant designed for crude palm oil

The full-continuous physical refining method edible oil refinery plant designed for crude palm oil

Secondly, your requirement for finished oil is also a factor. For high acid value crude oil, such as palm oil, palm kernel oil, rice bran oil and coconut oil, if you want to reduce FFA into small content, usually physical refining method is more suitable. So you need choose semi-continuous and full continuous edible oil refinery plant, which use direct steam to reduce FFA, belonging to physical refining method. While the deacidification process of batch type uses NaOH to neutralize FFA in the oil, which is chemical refining method. And during the process, the oil loss is larger than physical edible oil refinery plant.

Thirdly, your budget also can be a factor that affects your choice. Batch type edible oil refinery plant cost is the lowest, and the full continuous is highest, but the full continuous' the running cost and labor cost are both the lowest.

Our Henan Doing Mechanical Equipment Co.,ltd is a professional edible oil refinery plant manufacturer in China. We have exported lots of edible oil refinery plant to different counties. If you are interested in setting up an edible oil refinery plant, please contact us any time, and we will help you choose the best suitable edible oil refining method.

Leave a message

If you wanna to get more details about How many types of refining method are there in edible oil refining process?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

-

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company

A Kenyan client successfully ordered an integrated edible oil pressing machine and 2tpd edible oil refinery machine from Henan Glory Company

-

What is a comprehensive guide to setting up the best cpo refinery plant?

What is a comprehensive guide to setting up the best cpo refinery plant?

-

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

-

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria