The importance of steam deodorization in edible oil refining process

Steam deodorization is one of the main steps in edible oil refining process. Generally speaking, there is still a little odor substance after degumming and deacidification steps, and residual white clay and solvent(n-hexane) smell after decolorization step. Steam deodorization aims to remove these undesirable smells in edible oil, so that it won’t influence product oil quality.

Pure refined edible oil

Pure refined edible oil

In fact, pure edible oils are odorless, but most crude oils after pressing have different degrees "natural smell". Some are popular, such as sesame oil and peanut oil, but most are unpopular, especially the odor caused by rancidity and deterioration during edible oil refining process and storage. In addition, some oils have their special smell, such as sulfides in rapeseed oil, which must be removed. Thus, in order to get pure product oil, we need steam deodorization step to remove unpopular smells.

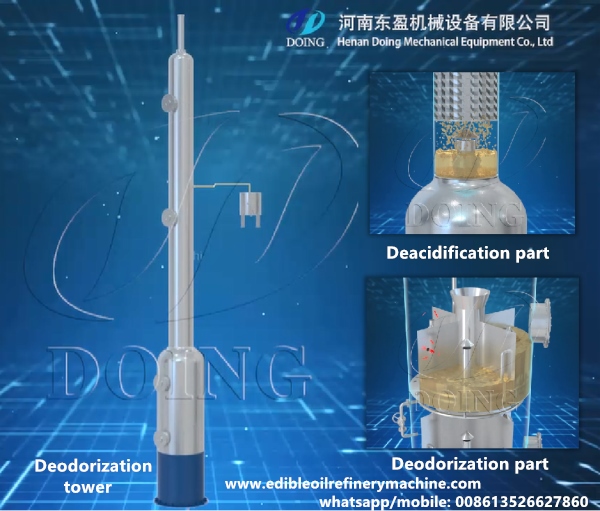

Steam deodorized tower in continuous edible oil refinery plant

Steam deodorized tower in continuous edible oil refinery plant

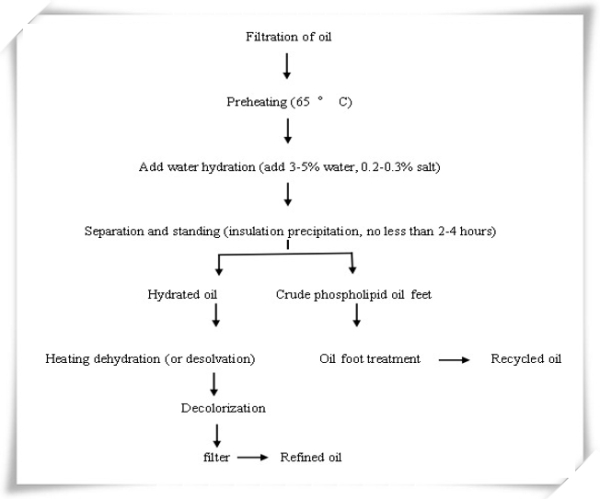

Some manufacturer’s edible oil refinery machine is very cheap. That is because they take rid of deodorization part so as to ensure more profit. See the following edible oil refining process flow chart they send to customers.

Other manufacturer’s edible oil refining process flow chart

Other manufacturer’s edible oil refining process flow chart

As you can see, this edible oil refining process flow chart doesn’t contain deodorization part, and the deacidification part and the time of separation and standing are not standard refining process.

Our one customer bought this kind of edible oil refinery machine, but the refined oil cannot meet the standard. He came to ask if we can retrofit his refining equipment or not. Our sales introduced the edible oil refining process flow chart of ours. Till that moment, this customer knew there isn’t deodorization part of his edible oil refinery plant.

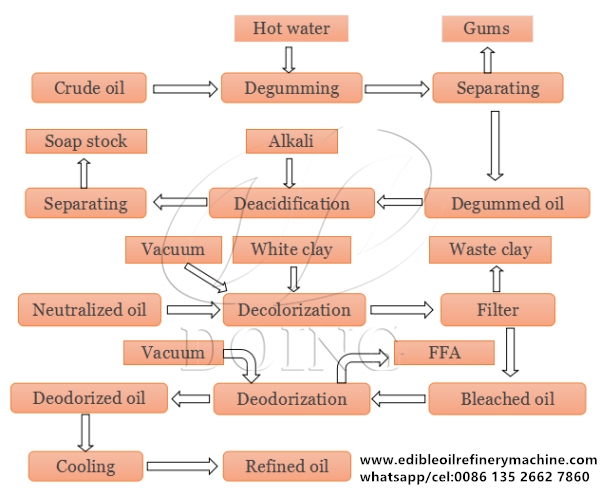

Henan Doing Company's edible oil refining process flow chart

Henan Doing Company's edible oil refining process flow chart

If only through neutralization and bleaching steps, actually we cannot see the difference of refined oil quality with eyes, but through testing, its quality is lower than the standard.

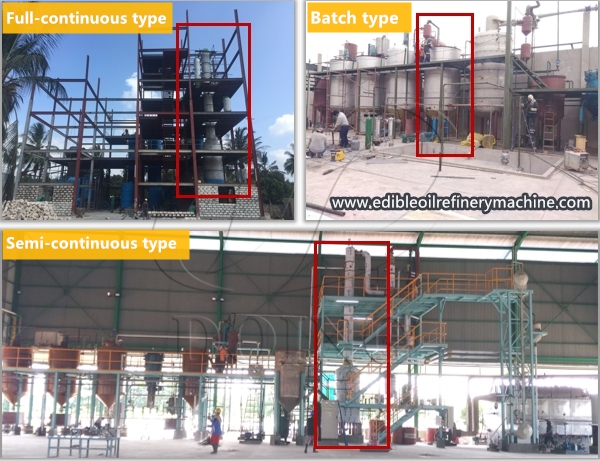

We Doing Mechanical Equipment Co.,ltd will supply to you complete edible oil refinery plant. Steam deodorized tank need 260 degree temperature, so its material must to be stainless steel. In this process, direct steam is mainly to promote the full mixing of oil, and expand the published area and facilitate the removal of odorous substances at a lower temperature. As the following pictures are the project cases of edible oil refinery plant we has installed.

The deodorization part in our edible oil refinery plant projects

The deodorization part in our edible oil refinery plant projects

So you can see, steam deodorization is indispensable in edible oil refining process. If you to set up an edible oil refinery plant or know more details of steam deodorization process, we welcome your asking!

PREV:Can vegetable oil refining plant produce fatty acid?

NEXT:Continuous palm oil physical refining process flow chart introduction

Leave a message

If you wanna to get more details about The importance of steam deodorization in edible oil refining process, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company