Continuous palm oil physical refining process flow chart introduction

Continuous palm oil physical refining process flow chart

Continuous palm oil physical refining process flow chart

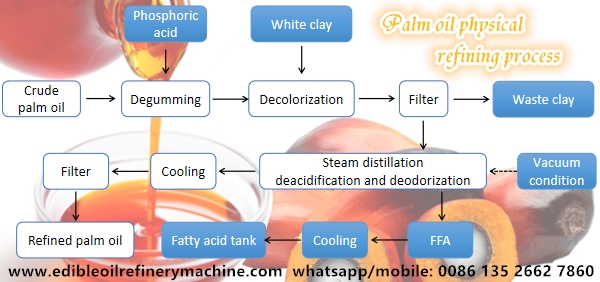

This continuous palm oil physical refining process flow chart is based on our engineers' designing palm oil physical refining technology, which is for 100tpd continuous palm oil refinery plant project in Kenya. It is different from other oil refining process, such as soybean oil refining process, sunflower oil refining process, etc. Because the refining process technology should be design according to the quality of crude oil and requirement of product oil.

Because of the main features of palm oil, less gum and high acid value, physical refining process technology is suitable for it. Usually more than 30 tons per day, palm oil refinery plant can be designed into continuous palm oil physical refinery plant.

As the above picture shows, there are four processing steps of the continuous palm oil physical refining process: degumming, decolorization(bleaching), deacidification and deodorization. These four steps will be processed in three devices of phosphoric acid reaction tank, decolorization tower, and deodorization tower.

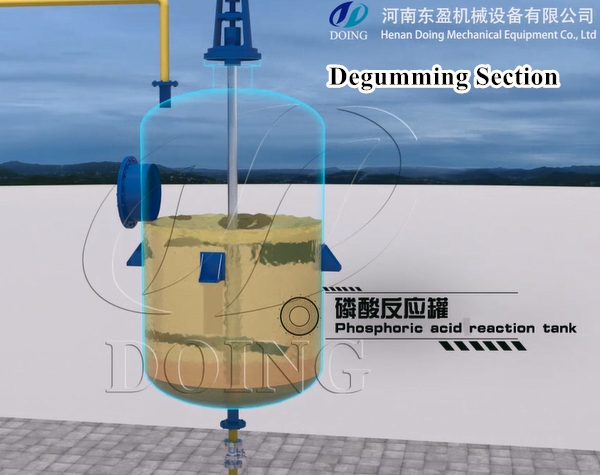

Degumming: The first step is heating the crude palm oil into 60-70 ℃, and then mixed the phosphoric acid with palm oil in the phosphoric acid reaction tank.

The phosphoric acid reaction tank in degumming section

The phosphoric acid reaction tank in degumming section

Because the gum percentage of palm oil is very less, it uses the dry degumming technology, not using hot water. The few gums will be absorbed by white clay in deacidification process.

Decolorization: During decolorization process, the required temperature of oil is 100-110℃. The oil after heating will be mixed with the white clay in white clay mixture tank, and then go into the decolorization tower.

The decolorization tower in decolorization section

The decolorization tower in decolorization section

There are plenty of small holes on the cover of white clay, which will adsorb the color of the palm oil. At last, separate the waste white clay by leaf filter.

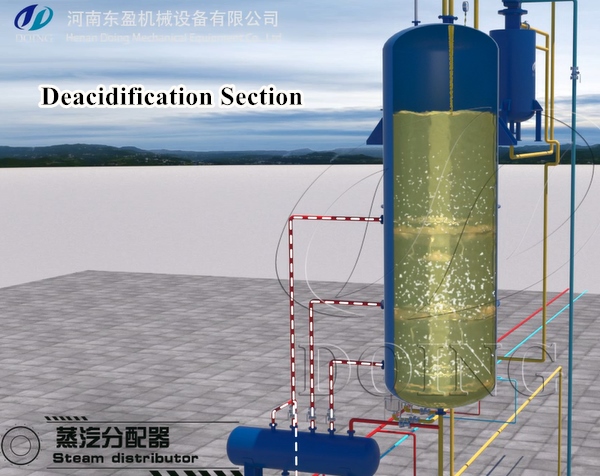

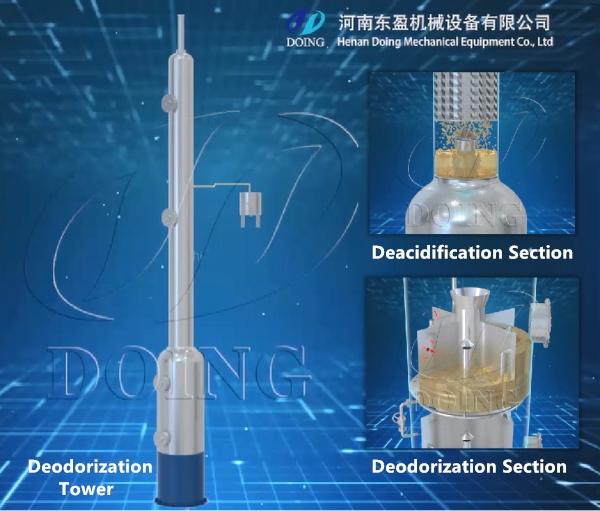

Deacidification and deodorization: Deacidification process and deodorization process are both in deodorization tower. On the top of tower is deacidification section, and on the bottom of tower is deodorization section. As the following picture shows.

The deodorization tower in decolorization and deodorization section

The deodorization tower in decolorization and deodorization section

Under the vacuum and high temperature the FFA(free fatty acid) and bad smell will be taken out. Because the required temperature of deodorization process is very high, about 260℃, the palm oil must be deoxidized to remove the oxygen in advance to avoid the palm oil oxidation and go bad. Besides, the required temperature of oil in deodorization section need use the special heating system of thermal oil furnace, because the steam heat transfer can not reach the required temperature.

Our engineers has designed many palm oil refinery plant for customers, from 2tpd to 100tpd input capacity. Henan Doing Company has rich experience in this filed. We will supply the latest palm oil refining technology for you.

PREV:The importance of steam deodorization in edible oil refining process

NEXT:The function of vacuum system in edible oil refinery plant

Leave a message

If you wanna to get more details about Continuous palm oil physical refining process flow chart introduction, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company

Rwanda customer ordered 5TPD palm oil fractionation machine from Henan Glory Company