What equipment is needed for a 5-10 ton cooking oil refining plant?

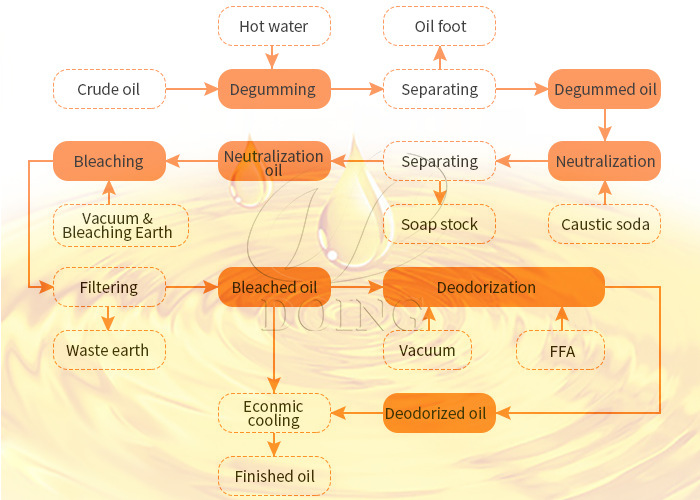

The refining of cooking oil is mainly to remove the colloidal impurities, free fatty acids, pigments and odors in the crude oil, so as to make the quality of cooking oil higher and safer. Therefore, in order to remove these impurities, the refining of crude oil will be divided into four sections: degumming, deacidification, decolorization and deodorization.

Cooking oil refining process

Cooking oil refining process

Factories refining 5-10 tons of cooking oil every day generally need batch type cooking refining machine with heat transfer oil as the heat source.

Degumming and deacidification section: because the degumming and deacidification processes are similar, only the chemicals added are different. In general, only one refining pot is needed to meet the processing of crude oil in these two sections. However, in order to improve the working efficiency, we designed two refining pots and included stirring blades in this link. During the refining process, we accelerated the reaction rate and improved the refining efficiency through continuous stirring. Otherwise, in this section, we will be equipped with an alkali tank, a hot water tank, and an alkali pump to assist in the degumming and deacidification process.

Degumming and deacidification machine

Degumming and deacidification machine

Decolorization section: the decolorization section mainly uses clay to adsorb the pigment in the oil. Therefore, we will first equip a decolorizing pot as the main reaction vessel, and then place a clay tank to store the clay.

After the decolorization section, because the clay will affect the deodorization section, we will add a blade filter between the decolorization tank and the deodorization tank to filter the clay in the decolorized oil. After that, the oil will enter the deodorization section.

Decolorization machine

Decolorization machine

Deodorization section: this section requires a high temperature and negative pressure environment, so we need a vacuum system to provide a vacuum environment for the deodorization tank. In order to provide a high-temperature environment, the deodorizing tank also contains a heat-conducting oil pan. At the same time, in order to ensure the quality of refined oil, the deodorizing tank is made of 304 stainless steel, which is safer. After the end of the deodorization section, we will add a bag filter to filter the oil finally.

Deodorization machine

Deodorization machine

In addition, a refinery also needs to be equipped with heat-conducting oil furnace, steam generator and other devices to provide the necessary environment for the refining of cooking oil.

Henan Company Glory have a professional team of engineers who can provide customized services according to your budget and needs. If you want more details, please feel free to contact us at :+86 13526627860

PREV:Cooking oil refining and fractionation machine display video

NEXT:How to build a batch type palm oil refinery with a fractionation plant?

Leave a message

If you wanna to get more details about What equipment is needed for a 5-10 ton cooking oil refining plant?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company