How to build a batch type palm oil refinery with a fractionation plant?

After the palm fruit is pressed, the crude red palm oil is obtained, but to obtain edible palm oil, it needs to be refined to meet the edible standard.

There are three types of common edible oil refining equipment, namely batch type edible oil refining equipment, semi-continuous edible oil refining equipment and fully continuous edible oil refining equipment. So under what circumstances is it suitable for batch type edible oil refining equipment?

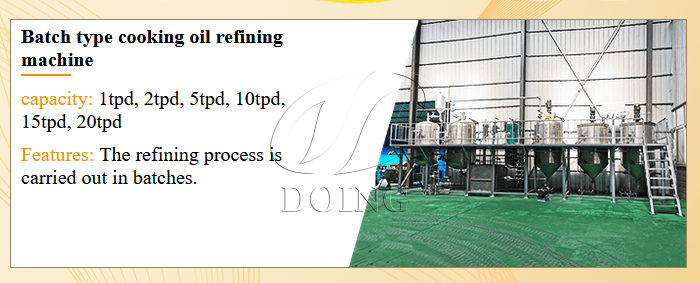

Batch type edible oil refining equipment

Batch type edible oil refining equipment

When the daily processing capacity is less than 20 tons, we recommend you to use batch type edible oil refining equipment because it is more cost-effective. So how to build a batch type palm oil refinery with a fractionation plant? One is to have raw material sources and factories, and the other is to know the technological process of palm oil refining and what equipment is included.

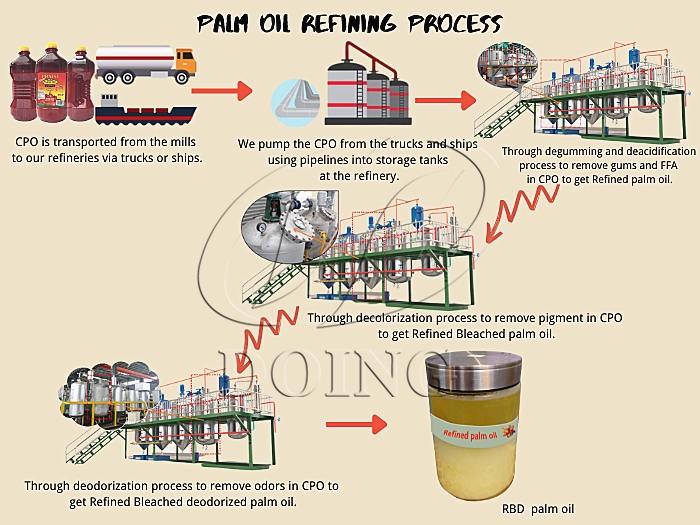

Palm oil refining technological process

Palm oil refining technological process

Palm oil refining includes degumming, deacidification, decolorization, and deodorization. Degumming and deacidification will be done in the first two refinery tanks. First, raise the temperature in the oil refining tank to 70-80 degrees, and add an appropriate amount of hot water to the crude palm oil under high temperature conditions. After stirring with the paddle in the tank, it will precipitate for 4-8 hours, then open the valve at the bottom of the refining tank to release the precipitate (micelle), then heat up again, add hot water and edible alkali (NaOH), and precipitate for another 4-8 hours , open the valve, release the precipitate (saponin, available for sale), and complete the degumming and deacidification.

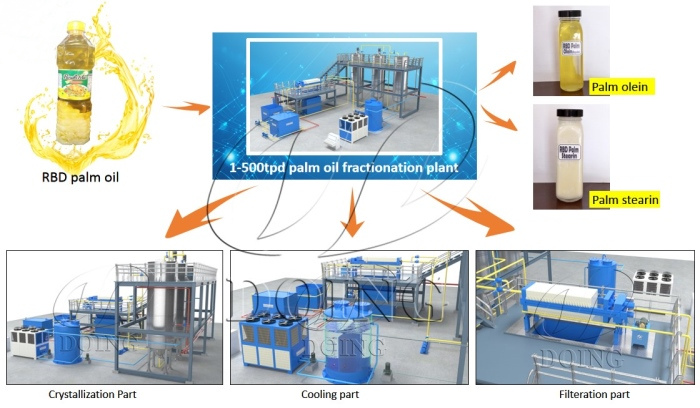

The next step is decolorization. The principle of decolorization is to use adsorbents to absorb impurities such as pigments in hot oil, and then filter them together. Therefore, this process requires high temperature, high vacuum and hot steam. The final step is deodorization. The principle of deodorization is that under high temperature conditions, the malodorous gas is more likely to volatilize, so the deodorization temperature needs to be around 260 degrees. Finally you need to be equipped with palm oil fractionation equipment. The fractionation process includes crushing of crystals, crystallization and filtration.

Palm oil fractionation equipment

Palm oil fractionation equipment

Generally speaking, carbon steel costs less than stainless steel. But some parts of the machine must use stainless steel to ensure the quality and longevity of the equipment. For example, the deodorizing tank in the refining process must be made of stainless steel because it is carried out at high temperatures. If carbon steel is used, oil will leak after a short period of use. Therefore, in order not to affect the production schedule, you'd better choose high-quality small-scale palm oil refining and fractionation machinery.

In addition to building a batch type palm oil refining plant with a fractionation plant, energy consumption needs to be considered. Batch type palm oil refining plant is suitable for limited cost or upfront investment. If you have needs, please contact Henan Glory Company, we will provide you with high-quality edible oil refining equipment and services.

PREV:What is the easy way to start cooking oil refining plant?

NEXT:What equipment is needed for a 5-10 ton cooking oil refining plant?

Leave a message

If you wanna to get more details about How to build a batch type palm oil refinery with a fractionation plant?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

The 0.5TPD edible oil refinery machine have been successfully shipped from Henan Doing company to Uganda

-

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria

Henan Glory Company shipped 1tph edible oil refining equipment to Nigeria

-

What's the timeline for the crude vegetable oil refining project?

What's the timeline for the crude vegetable oil refining project?

-

What factors contribute to the shipping expenses of palm oil refinery machinery to Nigeria?

What factors contribute to the shipping expenses of palm oil refinery machinery to Nigeria?

-

How do you reduce FFA in cooking oil?

How do you reduce FFA in cooking oil?

-

How to import cooking oil refining machines from China? What are the steps?

How to import cooking oil refining machines from China? What are the steps?