How do you reduce FFA in cooking oil?

Free fatty acids (FFA) are natural components present in all types of cooking oils. However, high levels of FFA can lead to undesirable flavors, decreased shelf life, and potential health hazards when oils are used for frying or cooking. Therefore, it's crucial to reduce FFA levels in cooking oils to maintain quality and safety. In this article, we will explore effective methods for reducing FFA in cooking oil.

Understanding Free Fatty Acids (FFA):

Free fatty acids are molecules consisting of a chain of carbon atoms with a carboxylic acid group at one end. They are naturally present in oils and fats and are released when oils undergo hydrolysis, a chemical reaction that occurs when oils are exposed to moisture, heat, or enzymes. High temperatures, prolonged storage, and exposure to air can accelerate hydrolysis, leading to increased FFA levels in cooking oils.

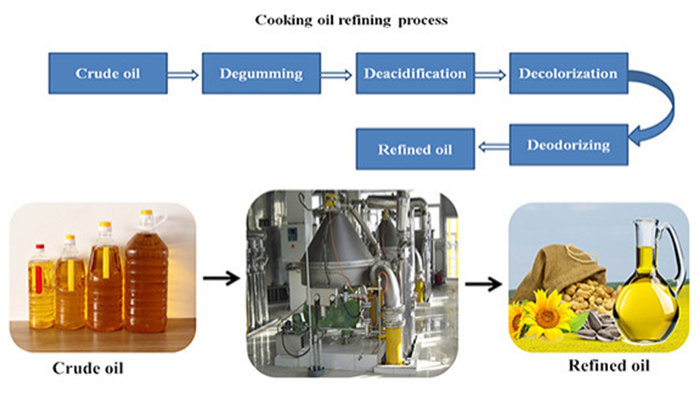

The process of cooking oil refinery

The process of cooking oil refinery

Methods to Reduce FFA in Cooking Oil:

1. Chemical Neutralization

Chemical neutralization is a method commonly used in oil refineries to reduce FFA levels. It involves treating the oil with an alkaline substance such as sodium hydroxide (caustic soda). The alkaline substance reacts with the free fatty acids to form soap, which can be separated from the oil. This process effectively reduces FFA levels.

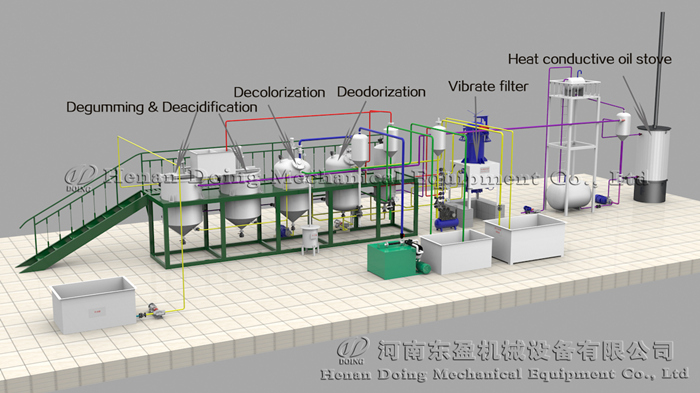

Cooking oil refinery plant

Cooking oil refinery plant

2. Physical Refining

Physical refining is another method used to reduce FFA levels in cooking oil. Unlike chemical refining, physical refining does not involve the use of chemicals such as caustic soda. Instead, it relies on processes such as steam distillation and vacuum distillation to remove free fatty acids and impurities from the oil.

The above is an introduction to the general methods of reducing FFA in cooking oil. In addition to neutralizing and removing F, the cooking oil refinery method generally includes degumming, decolorization and deodorization. Degumming removes impurities such as phospholipids, decolorizing helps remove pigments and other impurities, and deodorizing removes odor-causing compounds. That is, cooking oil refinery plants not only reduces FFA content but also improves the color, flavor, and stability of the cooking oil.

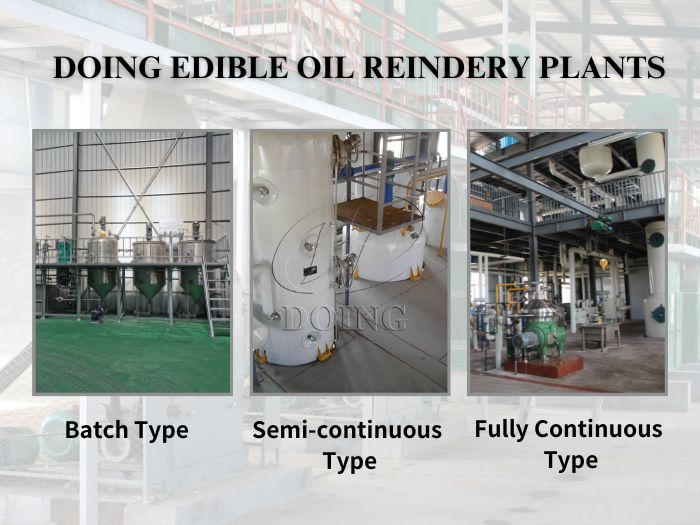

DOING cooking oil refinery plant

DOING cooking oil refinery plant

Henan DOING Company produces and designs different types of cooking oil refinery plants to meet the needs of different customers. If you are interested in our cooking oil refinery plants, please feel free to contact us.

PREV:What factors contribute to the shipping expenses of palm oil refinery machinery to Nigeria?

NEXT:How to import cooking oil refining machines from China? What are the steps?

Leave a message

If you wanna to get more details about How do you reduce FFA in cooking oil?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?