How poor edible oil deodorization design can affect your profits?

In the modern oil processing industry, edible oil, as an important oil, is widely used in food, cosmetics and many other industries. The edible oil deodorization process is a crucial part of it. Deodorization is not only related to the quality and flavor of the product, but also directly affects the production cost and final profit. In this article, we'll explore how poor deodorization design design can affect your profit.

1. Affecting the quality of oil products and damaging the brand image

The purpose of edible oil deodorization is to remove odors, impurities and harmful substances in the oil to ensure the cleanliness and flavor of the product. Poor edible oil deodorization design may cause the oil to have odor or impurity, reducing the quality of the product. This will not only affect the consumer's experience, but also damage the brand image, thereby affecting sales. If consumers cannot trust your product, your market share will be greatly reduced, indirectly affecting your profits.

2. Increasing production costs

The edible oil deodorization design directly affects production efficiency. If the edible oil deodorization equipment is not properly configured, it may lead to incomplete edible oil deodorization, slow production process, and even repeated processing, which not only wastes time, but also increases energy consumption, leading to higher production costs. High production costs will weaken your profit margins, especially in a highly competitive market environment, where price advantages will not be fully reflected.

Edible oil deodorization equipment

Edible oil deodorization equipment

3. Impacting on product stability and storage period

Poor edible oil deodorization design may result in some unstable components remaining in the oil, which will affect the preservation and stability of edible oil. The quality and storage period of edible oil are important factors affecting consumers' purchasing decisions. If the oil is easily oxidized and deteriorated, consumers may choose a more reliable brand. In addition, the short shelf life of oil also means that the product needs to be sold and circulated more frequently, increasing management costs and losses.

4. Reducing production efficiency and affect output

Poor edible oil deodorization design often leads to inefficiency in the production process. It takes longer to complete edible oil deodorization, or the repair cycle is longer when the edible oil deodorization equipment fails. Since the output cannot meet the market demand, it may cause a situation of supply exceeding demand and miss sales opportunities. In addition, low production efficiency may also affect other links of the edible oil production line, resulting in a decline in overall benefits.

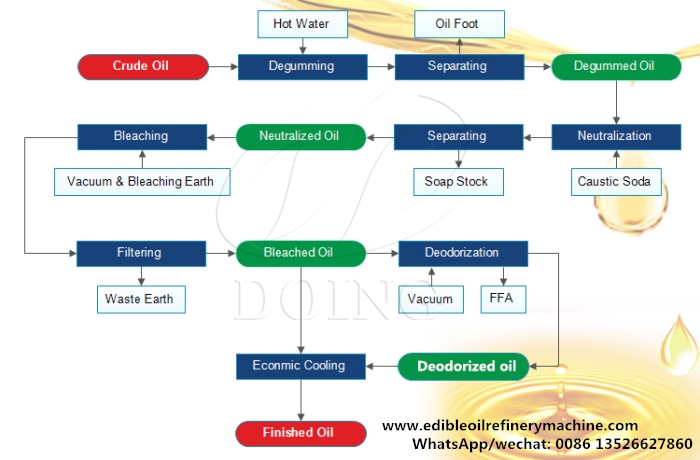

The edible oil refining line

The edible oil refining line

5. Limiting market expansion and product diversity

The quality of edible oil deodorization design directly affects the adaptability of the product. If the edible oil deodorization design cannot ensure the diversified production of oil products, it may limit the expansion of products in different markets. For example, different industries and consumers have different demands for oils and fats, and a good edible oil deodorization design can help meet these different demands. On the contrary, poor edible oil deodorization design may result in products that can only meet part of the market demand, limiting the company's market expansion and profit opportunities.

In general, the role of edible oil deodorization design in oil processing cannot be ignored. Therefore, enterprises should focus on optimizing and improving edible oil deodorization technology to ensure the stability of oil quality, reduce production costs and increase profit margins, so as to remain invincible in the fiercely competitive market. If you have any further questions about the affect of poor edible oil deodorization design on profits, please consult Henan Glory Company and we will answer you in detail!

Leave a message

If you wanna to get more details about How poor edible oil deodorization design can affect your profits?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

10tpd cooking oil refining plant is under installation in Kenya

10tpd cooking oil refining plant is under installation in Kenya

-

Henan Glory to supply 1tpd edible oil refinery machine to Guinea client

Henan Glory to supply 1tpd edible oil refinery machine to Guinea client

-

Henan Glory secures central Africa order for small edible oil refinery plant (200kg/d)

Henan Glory secures central Africa order for small edible oil refinery plant (200kg/d)

-

Nigeria: 50tpd palm oil refining & 30tpd fractionation equipment deal signed

Nigeria: 50tpd palm oil refining & 30tpd fractionation equipment deal signed

-

Burundi client boosts oil quality with 5tpd palm oil fractionation machine from Henan Glory

Burundi client boosts oil quality with 5tpd palm oil fractionation machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria