Edible Oil Physical Refining vs Edible Oil Chemical Refining

Physical refining and chemical refining are two main refining methods in edible oil processing. Their purpose are both to remove the gum, free fatty acid, pigment and odor in edible oil, so as to make the edible oil achieve better quality. However, there are also great differences between the two refining methods. Next, we mainly introduce the differences between the two refining methods from two aspects: the applicable types of crude oil and the processing technology.

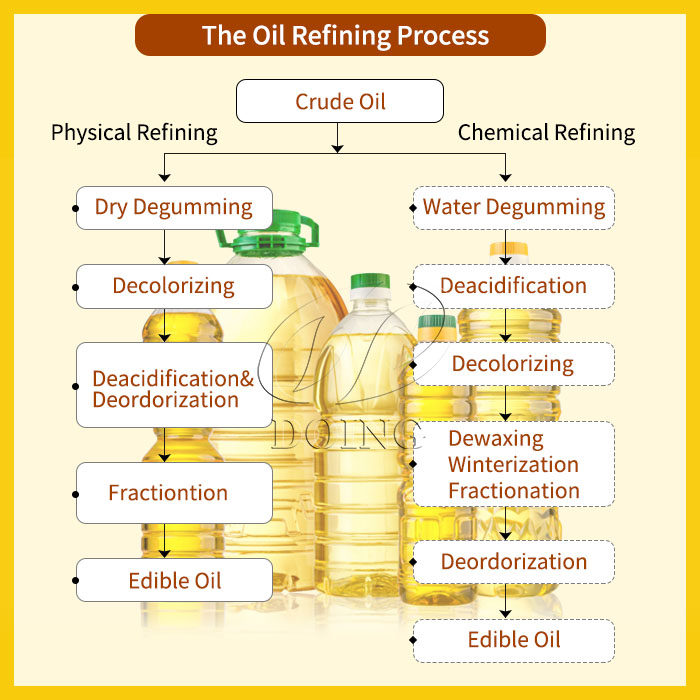

Edible oil physical refining process and edible oil chemical refining process

Edible oil physical refining process and edible oil chemical refining process

Types of crude oils suitable for processing:

Crude oils with low gum content and high free fatty acid content, such as palm oil, palm kernel oil and coconut oil, are processed through physical refining. Sunflower seed oil, peanut oil, soybean oil, cottonseed oil, rapeseed oil and other common edible oils can be chemically refined.

About processing technology:

Physical refining: As the crude oil processed by physical refining has less gum content and higher free fatty acid content, degumming and decolorization will be carried out together during physical refining, and the deacidification and deodorization will be treated in the same way. That is, phosphoric acid will be added into the crude oil to remove a small amount of gum in the crude oil. Then clay is added to adsorb the pigment in the oil. After degumming and decoloriaction, the crude oil is filtered through the blade filter to remove impurities such as clay and gum in the crude oil. It enters the deacidification and deodorization tower, where free fatty acids and odor in the crude oil are removed through the action of high-temperature and high vacuum steam without adding other chemical reagents. Generally, the temperature of deacidification and deodorization tower will reach about 240 ℃.

Chemical refining: The chemical refining process can be divided into four parts: degumming, deacidification, decolorization and deodorization. In the degumming section, phosphoric acid or hot water will be added to separate the colloidal impurities in the oil from the crude oil. In the deacidification section, alkali liquor is added to make the alkali liquor react with free fatty acid to produce soap stone and remove free fatty acid from the crude oil. This link is also the biggest difference from physical refining. The next step is decolorization. The clay or activated carbon and other adsorbents are added to the crude oil to remove the pigment in the crude oil. Finally, the deodorization section, in which the peculiar smell in the crude oil will be removed under the high temperature and high vacuum environment.

About handling capacity:

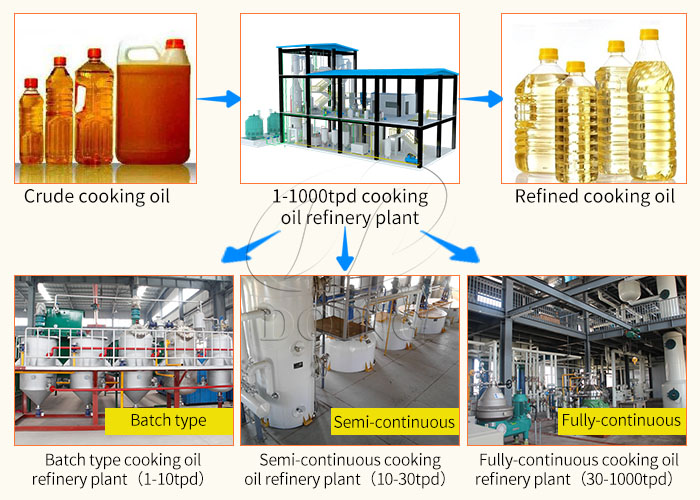

Chemical refining: The minimum processing capacity is 0.5TPD, which means you can process 0.5t of crude oil in 24 hours. The maximum processing capacity is 500 TPD.

Physical refining: In general, our minimum equipment capacity is 30TPD.

Edible oil refining equipment with different processing capacity

Edible oil refining equipment with different processing capacity

If you want to know more about refining equipment, you can contact us at any time. We have a professional team of engineers, who can provide a pair of customized services according to your specific needs, and a professional sales team to provide you with purchasing advice. Our contact information is:+86 13526627860

PREV:How to refine peanut oil processed in small workshops?

NEXT:What advice can you give in order to produce well refined sunflower oil?

Leave a message

If you wanna to get more details about Edible Oil Physical Refining vs Edible Oil Chemical Refining, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company