How to choose suitable edible oil refinery machine? How much is its price?

Edible oil refining is a complex but flexible task that requires the selection of suitable refinery machine according to the daily processing capacity, investment budget and economical benefits. Depending on the degree of automation, there are three different types of edible oil refinery machine, namely batch edible oil refinery machine, semi-continuous refinery machine and full continuous refinery machine. Henan Glory Company engineers recommend that you can choose suitable refinery machine depending on the daily processing capacity of your plant, the degree of oil refining and investment budget.

Different types of edible oil refining machines

Different types of edible oil refining machines

The following are three types of refinery machine are suitable for different situations and can meet your diverse needs.

If the daily processing capacity of your plant is below 20 tons, Heanan Glory Company recommends you to choose batch edible oil refinery machine. All sections in the batch edible oil refinery machine are carried out in batches, with a daily processing capacity of 1-20 tons per day, which is suitable for small scale edible oil refinery plant. For manufacturers with a limited initial investment budget or a small daily processing capacity, this machine is sufficient to meet daily production needs.

Batch type edible oil refinery machine

Batch type edible oil refinery machine

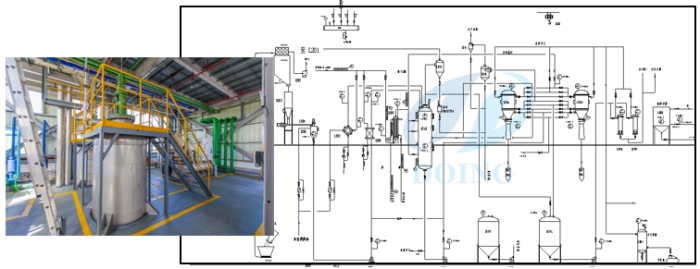

If your production is stable and keeps above 50 tons per day, Henan Glory Company recommends you to choose the full continuous refinery machine. The process of full continuous refinery machine is fully automated and continuous, saving a lot of manpower and material resources, with high production efficiency, good refining effect and high economic benefits, suitable for large scale edible oil refinery plant.

Full continuous refinery machine

Full continuous refinery machine

Semi-continuous refinery machine perfectly combines the characteristics of batch refinery machine and full continuous refinery machine. In the semi-continuous refining process, degumming, deacidification and decolorization are carried out in batches, while deodorization is carried out continuously. This machine not only ensures the effectiveness and efficiency of the edible oil refining, but also reduces the investment budget, making it more suitable for large and medium scale edible oil refinery plant with high requirements for edible oil and limited investment budgets.

As for the price of refinery machine, it is determined by the degree of refining treatment required by the customer, daily processing capacity, the material of machine etc., I can only provide you with a general range for reference only. The processing capacity determines the specification and configuration of the refinery machine. The larger the processing capacity, the higher the price. The degree of oil refining determines the specification and configuration of the refinery machine. In addition, the material and quality of the machine are also factors that affect the price of refinery machine.

The three different types of edible oil refinery machine have different characteristics and advantages, as the saying goes, fitness is the best, so choose the suitable refinery machine according to your situation and needs. As a manufacturer of edible oil processing machine, Henan Glory Company can customize the edible oil refinery process and refinery machine to fit your needs. If you have any questions, please contact us!

Leave a message

If you wanna to get more details about How to choose suitable edible oil refinery machine? How much is its price?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company