What are the processes in edible oil refinery plant?

Edible oil refining processes in edible oil refinery plant are to refine the crude cooking oil, get rid of impurities. And then get the high quality edible oil. The common refining processes are degumming, deacidification, decolorization and deodorization. Some oilseeds need dewaxing or fractionation. Now, let’s discuss it together.

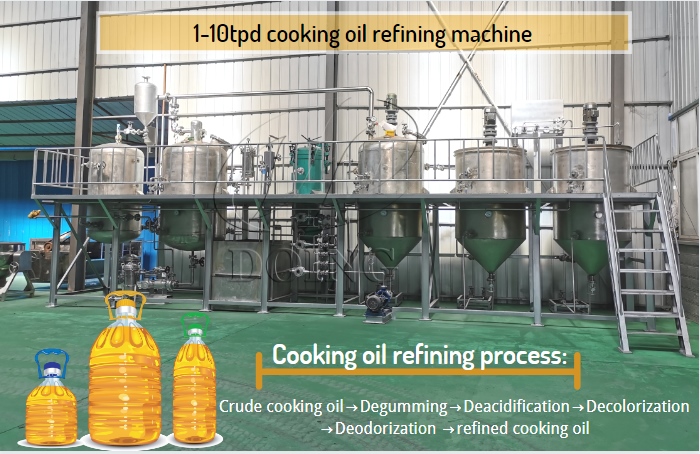

Small scale edible oil refinery plant

Small scale edible oil refinery plant

Degumming and deacidification processes:

Degumming is the first and basic step in the crude oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods. Water-degumming is suitable for most oilseeds. While acid-degumming is often used for palm oil. At the same time, deacidification is carried out. Chemical deacidification is often used, that is, adding alkali liquor into crude oil to neutralize with free fatty acids, so as to achieve the effect of deacidification. At the end, the soaps got from reactions are separated from the oil.

Decolorization process:

Decolorization, also called bleaching, is to remove color pigments contained in Neutralized Oil. At present, the most widely used method is adsorption, that is, the clay with strong adsorption capacity is added into the oil, and the pigment and other impurities in the oil are removed by adsorption under heating. After lowering the bleached oil temperature, pump the oil and clay mixture into vibrating filter to remove the waste clay, and the decolorization process is finished.

Deodorization process:

Generally speaking, deodorization process is the final stage in edible oil refining process. The decolorized oil is subjected to steam distillation under condition of high temperature and vacuum to remove bad smell, free fatty acids and other undesired minor components.

Generally, many kinds of oils in edible oil refinery plant have been refined after the above four processes. But some oils need dewaxing and separation because of their own particularity. Now, let’s move on to dewaxing and fractionation.

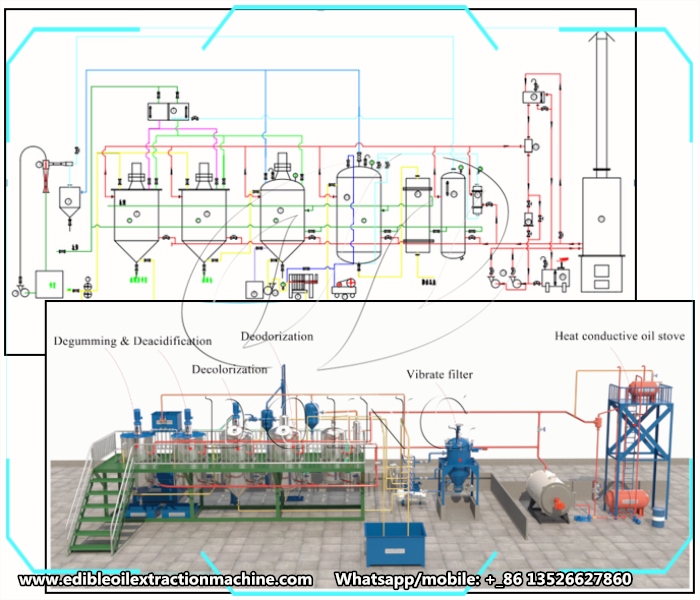

Edible oil refinery process flow chart

Edible oil refinery process flow chart

Dewaxing process:

Sunflower seed oil, corn germ oil, rice bran oil, cottonseed oil need dewaxing to change quality and improve flavor. The existence of wax not only affects the transparency and taste of oil, but also affects the health of human body. Dewaxing is a process of separating high melting point wax and high melting point solid grease from oil by cooling and crystallization, and then removing them by filtration or centrifugal separation.

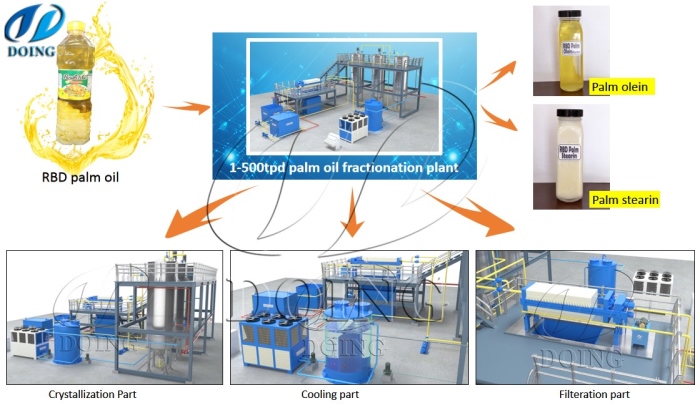

Fractionation process:

In order to make rational use of palm oil and palm kernel oil, it is necessary to fractionate it and make a variety of products. Palm oil fractionation is to control the cooling process of palm oil and separate it into low melting point liquid phase (palm olein) and high melting point solid phase (palm stearin). Palm oil can be divided into three parts: palm stearin, palm olein and palm midfraction. Dry fractionation is one of the most economical methods. It refers to the method of cooling the dissolved oil slowly to a certain extent without adding any solvent, then filtering, separating and crystallizing to precipitate solid fat. Dry fractionation is usually divided into three steps: heating treatment, crystallization and crystal growing and filtration.

Palm oil fractionation plant

Palm oil fractionation plant

The above is a brief analysis of processes in edible oil refinery plant. There will be a little difference in refining steps of different oil products. Henan Glory Oils & Fats can design specific refining process and equip with corresponding equipment according to your oilseed and daily production.

PREV:Why people tend to choose small scale edible oil refinery plant to produce cooking oil?

NEXT:What is the purpose of cooking oil refining? What's the refining steps of cooking oil?

Leave a message

If you wanna to get more details about What are the processes in edible oil refinery plant?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company