Cooking oil refining process and cooking oil refining machine

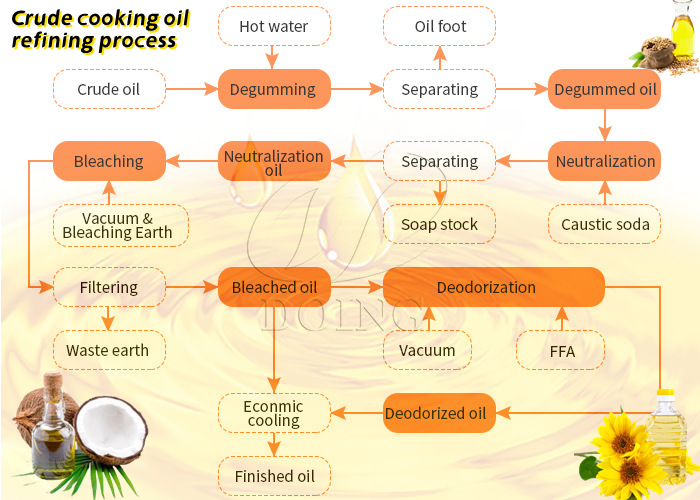

What are the basic steps of cooking oil refining? It mainly includes four steps of degumming, deacidification, decolorization and deodorization. In the whole refining process, due to different process requirements, the materials of the machines used are different. In order to let everyone better understand the process of cooking oil refining and cooking oil refining machine,I will analyze and explain from the following points:

Cooking oil refining process

Cooking oil refining process

The first is the degumming and deacidification process, because these two processes are carried out in one machine (alkali boiler), so they are introduced together. After the crude cooking oil enters the alkali smelting pot, add hot water at about 80°C, react with the phospholipid molecules in the oil to form micelles, precipitate and discharge to achieve the purpose of degumming, and then add the mixture of water and cooking alkali and the free in the oil. The fatty acid reacts to form soapstock after precipitation, which is discharged to achieve the purpose of deacidification. The precipitation time of each section is 6-8h.

Degumming and deacidification machine

Degumming and deacidification machine

Then there is our decolorization process. The deacidified oil enters the decolorization pot, and the adsorbable clay is added to the pot. After about 30 minutes of adsorption, the deacidified oil will flow into the leaf filter, and the clay inside will be filtered out. Decolorized oil is obtained.

Cooking oil decolorization machine

Cooking oil decolorization machine

Finally, the decolorized oil flows into the deodorization pot, and the temperature in the pot is raised to about 260 ° C, and the high temperature makes the odor and water in the oil evaporate, so as to achieve the purpose of deodorization.

Cooking oil deodorization machine

Cooking oil deodorization machine

In order to prevent the refined cooking oil from being oxidized at high temperature in the air, it is necessary to reduce the oil temperature to about 60°C in the deodorization pot, and then transport the refined oil to the tanker.

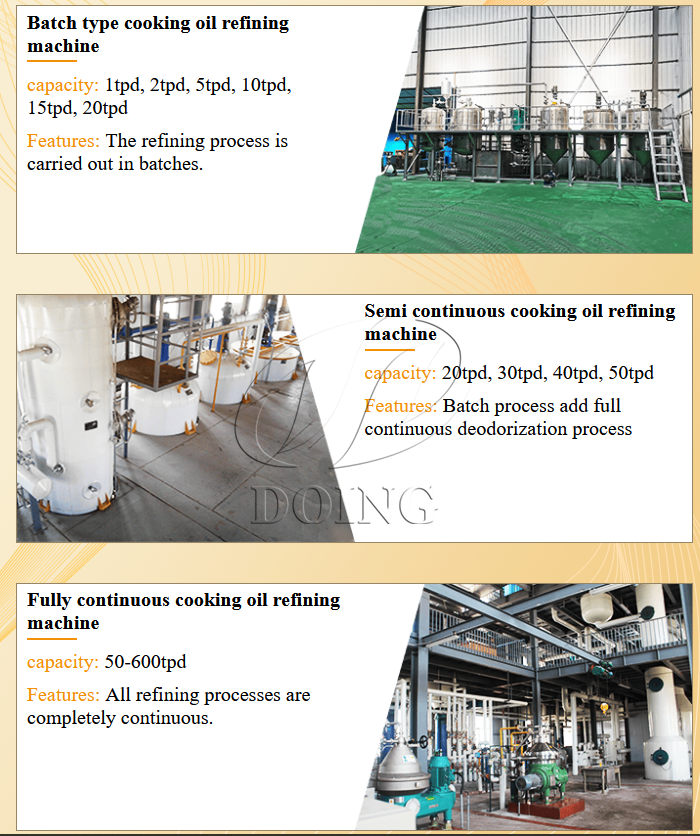

In order to obtain high-quality refined cooking oil, in addition to conventional operating processes and normal-quality crude cooking oil, high-quality cooking oil refining machine is also essential. Therefore, with the joint efforts of the engineers and skilled workers of Henan Glory Company, the quality and efficiency of our cooking oil refining machine are remarkable.

Our cooking oil refining machine adopts the most advanced CE and ISO9001 certified cooking oil refining lines to obtain refined oil with high purity and high oil yield. We provide physical and chemical refining technologies and are able to provide customers with the most affordable cooking oil refining solutions, including design, manufacture, installation as well as quality assurance and reliable service.

Cooking oil refining machine of Henan Glory Company

Cooking oil refining machine of Henan Glory Company

Heating equipment: As far as our heating coils are concerned, since the heat transfer oil needs to be transported inside, the heating coils of all our boilers are seamless pipes, which avoids the heat transfer oil from penetrating into the crude oil and causing the pollution of the crude oil. And our heat transfer oil furnace can use various fuels, such as natural gas, firewood, gas, etc., to meet the different needs of customers.

Vacuum environment: Both the decolorization and deodorization sections need to be carried out in a vacuum environment, so we specially configure a water jet vacuum pump to provide a vacuum environment for these two boilers to achieve high-efficiency and high-quality production.

Filtration equipment: Our leaf filter can be cleaned automatically, which saves the time and cost of manual cleaning to a certain extent.

Filtration equipment-leaf filter

Filtration equipment-leaf filter

Deodorizing pot: The last is our deodorizing pot, which is made of stainless steel as a whole to avoid the use of carbon steel to generate harmful substances-manganese when exposed to high temperature.

It is worth mentioning that our cooking oil refining machine can process various crude cooking oils such as peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, etc., and can also customize the corresponding cooking oil refining production line for you according to your processing capaciy.If you are interested in cooking oil refining business, please contact Henan Glory Company!

Related products:

PREV:How much does batch type edible oil refining machine cost?

NEXT:How many budget is needed to start a palm oil refining business in Nigeria?

Leave a message

If you wanna to get more details about Cooking oil refining process and cooking oil refining machine, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company