Why does the cooking oil refining process include degumming, deacidification, deodorization and decolorization?

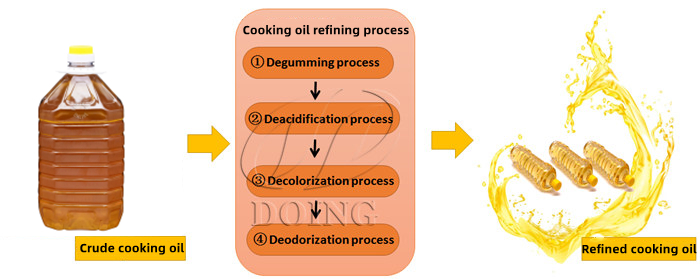

The main purposes of cooking oil refining process is to remove harmful impurities, undesirable odor, flavor, and color in crude cooking oil through degumming, deacidification, decolorization and deodorization process, so that we can obtain pure and relatively non-impurities of high-quality cooking oil. Next, I will briefly the reasons and specific practices of each cooking oil refining steps helping everyone to get familiar with the whole progress.

Four steps of cooking oil refining progress

Four steps of cooking oil refining progress

1. Degumming

Reason: Crude cooking oil contains various impurities,like, gum, which will affect the quality and stability of the oil, as well as the subsequent sections of cooking oil refining, which need to be removed by degumming.

Specific practice: Generally, crude cooking oil has less gum, and can be degummed by dry method, that is, adding phosphoric acid solution to crude cooking oil in order to make peptized impurities into agglomerates, and the peptized impurities can be removed after sedimentation.

2. Deacidification

Reason: Deacidification aims to remove free fatty acids in crude cooking oil to avoid oil rancidity and improve the stability of cooking oil.

Specific practice: Cooking oil batch refining equipment generally uses chemical deacidification to remove free fatty acids, which is to add lye to crude cooking oil to neutralize it with free fatty acids. The soap would be formed after neutralizing, which be removed after edimentation, thereby the free fatty acids is removed.

3. Decolorization

Reason: The purpose of decolorization is to remove the pigment in crude cooking oil, so that the color of cooking oil is clearer.

Specific practice: The specific operation process of decolorization is to add clay to crude cooking oil to absorb pigments and other impurities in the oil, and then use the leaf filter to filter out the waste clay in the oil.

Tips: The feeding amount of white clay can be controlled according to the needs of customers, so that the color of cooking oil can reach the standard.

4. Deodorization

Reason: Crude cooking oil has an odor, which affects the flavor and value of cooking oil and needs to be removed by deodorization.

Specific practice: Deodorization is to inject direct steam into crude cooking oil, and take advantage of the difference in volatility between oil and odorous substances to take away odors. After deodorization, the quality of cooking oil is improved, and the smoke point and stability are also improved.(Related reading:100TPD palm oil refinery and fractionation plant project report in Kenya)

Cooking oil refining plant

Cooking oil refining plant

As a professional manufacturer of cooking oil refining machine, we can provide a series of equipment to help people to make refined cooking oil. If you are interested in cooking oil refining machine and its prices, feel free to call us.

Leave a message

If you wanna to get more details about Why does the cooking oil refining process include degumming, deacidification, deodorization and decolorization?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company