How to refine sunflower oil in South Africa?

There are generally two processes to refinery sunflower oil: physical and chemical refinery process. In South Africa, most people choose the chemical refinery process, and through the sunflower oil refinery machine to carry out degumming, deacidification, decolorization, deodorization process. The following will introduce the difference between the physical the chemical refinery process of sunflower oil and why more people in South Africa choose chemical refinery process to refine sunflower seed oil.

1. The difference between physical and chemical refinery processes

The main difference between physical refinery and chemical refinery is the method used in the deacidification process, that is, whether alkaline chemicals are used for deacidification. Chemical refinery process achieves the purpose of deacidification by adding sodium hydroxide to neutralize acid. Physical refinery process removes free fatty acids through high-temperature steam.

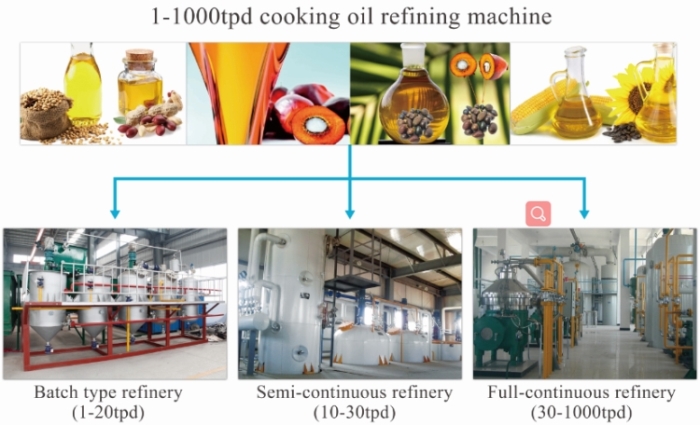

Different types of Glory sunflower oil refinery machines

Different types of Glory sunflower oil refinery machines

According to the needs of sunflower oil refinery in South Africa, Henan Glory has produced a variety of models (batch, semi-continuous and fully continuous) of sunflower oil refinery machines to choose from. The batch sunflower oil refinery machine only uses chemical refinery process, while the fully continuous type uses chemical and physical refinery process.

2. Why do most people choose to refine sunflower oil through the chemical refinery process in South Africa?

2.1 Background and resources:

South Africa is one of the major countries in sunflower production and has abundant sunflower seed resources. Chemical refinery process can efficiently process large quantities of sunflower seeds through more complex processes to achieve higher yields and lower costs. This is important for South Africa's production environment and economic viability.

Sunflower oil refinery machine

Sunflower oil refinery machine

2.2 Quality requirements:

Chemical refinery process is better able to meet the quality requirements. Sunflower edible oil exported from South Africa often must meet strict quality standards, such as food safety and regulatory requirements of the exporting country. Sunflower oil chemical refinery process can more thoroughly remove impurities, impure substances and harmful ingredients, thereby improving the quality and stability of the oil.

3. The 3D video of Henan Glory batch sunflower oil refinery machine process

The following is take Glory batch sunflower oil refinery machine as an example to show you the sunflower oil refining process, including degumming, deacidification, decolorization, deodorization:

The above is an introduction of the sunflower oil refinery process in South Africa. If you are interested in our sunflower oil refinery machines, you can contact us at any time. Our Henan Glory company has been developing for many years and has rich experience. Our project manager can introduce you to the machine details and make a free quotation. In addition to selling sunflower oil refinery machines in South Africa, we also sell various vegetable oil production lines, such as sunflower seed, soybean, peanut, cottonseed, rapeseed, sesame, etc. Welcome to consult us!

Leave a message

If you wanna to get more details about How to refine sunflower oil in South Africa?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

-

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?