Can one cooking oil refining plant process varieties of crude oil?

The answer is yes, a cooking oil refining plant can handle all kinds of crude oils, because the purpose and process of cooking oil refining are the same.

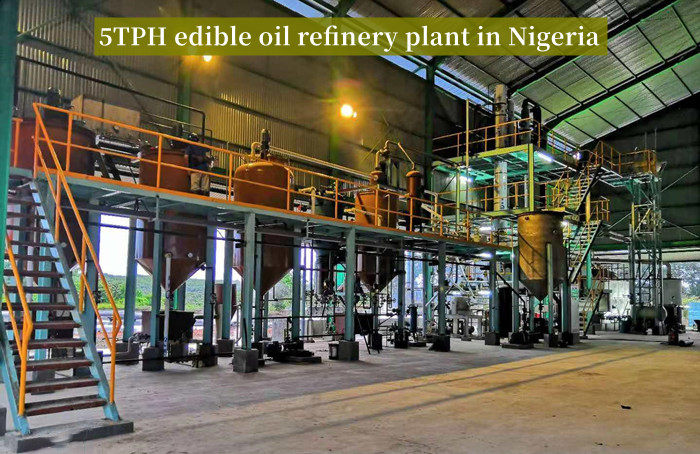

5TPH cooking oil refining plant in Nigeria

5TPH cooking oil refining plant in Nigeria

1. The purpose of cooking oil refining

Some impurities in crude oil will seriously affect the smooth processing of oil, affect the safe storage of oil, and reduce the quality and use value of oil. Harmful impurities in cooking oil must be removed in order to ensure the quality of cooking oil and to obtain oil suitable for industrial requirements. The purpose of cooking oil refining is to remove harmful components in oil and reduce the loss of neutral oil and beneficial components as much as possible according to different uses and requirements.

2. The process of cooking oil refining

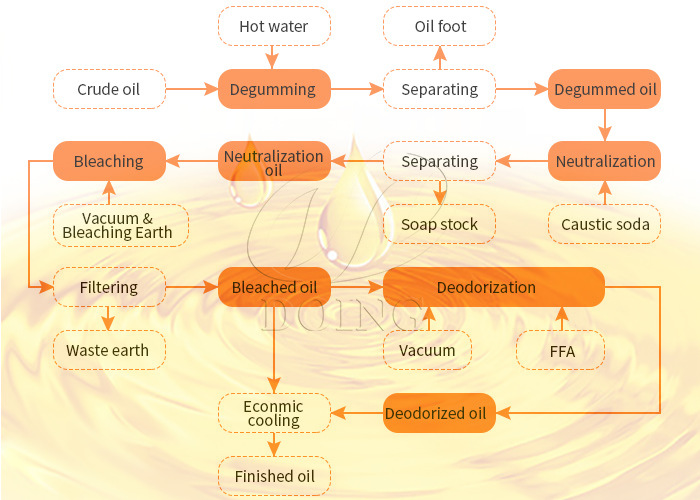

Cooking oil refining process

Cooking oil refining process

(1)Hydration degumming

Hydration degumming refers to the use of phospholipid and other colloidal impurities hydrophilicity, in crude oil stirring while adding a certain amount of water or electrolyte dilute solution, so that the colloidal impurities in crude oil water absorption, swelling, agglomeration, separation degumming method. In the process of hydration and degumming, phospholipid is the main substance that can coagulate and precipitate except protein, mucus and trace metal ions.

(2) Alkali deacidification

All unrefined crude oils contain a certain amount of free fatty acids. The process of removing free fatty acids from crude oils is called deacidification. Deacidification methods include alkali refining, distillation, solvent extraction and esterification. Alkaline refining and steam distillation (physical refining) are widely used in industrial production.

(3) Adsorption decolorization

Oil adsorption decolorization is the use of some substances (such as bleached soil, active clay, activated carbon, etc.). It has strong selective adsorption for pigment, adsorbing impurities such as pigment in oil under certain conditions, so as to achieve the purpose of decolorization. The oil treated by adsorbent can not only improve the color of the oil, remove the colloid, but also effectively remove some trace metal ions and some substances that can cause poisoning of hydrogenation catalyst, thus providing a good condition for further refining (hydrogenation and deodorization).

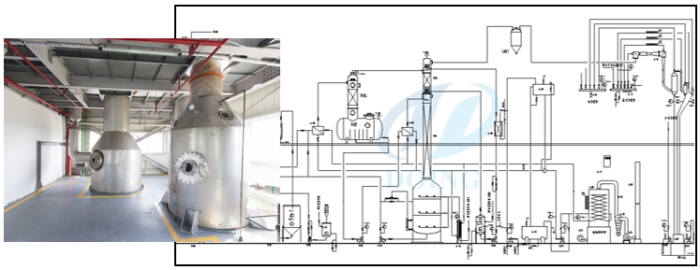

Cooking oil adsorption deodorization equipment

Cooking oil adsorption deodorization equipment

(4) High temperature deodorization

High temperature deodorization is a process of removing abnormal odor substances by steam distillation under high temperature and high vacuum by taking advantage of the difference in volatilization of odor substances in fats and triglycerides. The principle of steam distillation deodorization (also known as stripping) is that water vapor through oil containing odor components, vapor liquid surface contact, water vapor is saturated with volatile odor components, according to its partial pressure ratio escape, so as to achieve the purpose of eliminating odor components.

Through the above introduction, you have a certain understanding of cooking oil refining. As a professional cooking oil refining equipment manufacturer, if you want to refine a variety of cooking oil, but the budget is limited, welcome to contact Henan Glory Company, we will customize the appropriate production plan for you.

Leave a message

If you wanna to get more details about Can one cooking oil refining plant process varieties of crude oil?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company