How many types of cooking oil refining machine does Henan Glory Company have for sale?

As a manufacturer of cooking oil refining machine with more than ten years of experience, Henan Glory Company has various types of cooking oil refining machine on sale according to different heating methods, refining processes and processing capabilities. If you are interested in cooking oil refining machine If you are interested, please read on!

1. According to different heating methods, it can be divided into electric heating type and conduction oil heating type.

Electric heating type and conduction oil heating type

Electric heating type and conduction oil heating type

Electric heating refining is suitable for a capacity of 0.5-2tpd. The characteristic is that resistance wire is used to heat crude oil, which requires less investment, but requires high voltage stability and consumes a lot of power. The conduction oil heating type is suitable for processing more than 1 ton. Using conduction oil to heat crude oil requires a thermal oil furnace, but is more economical in the long run.

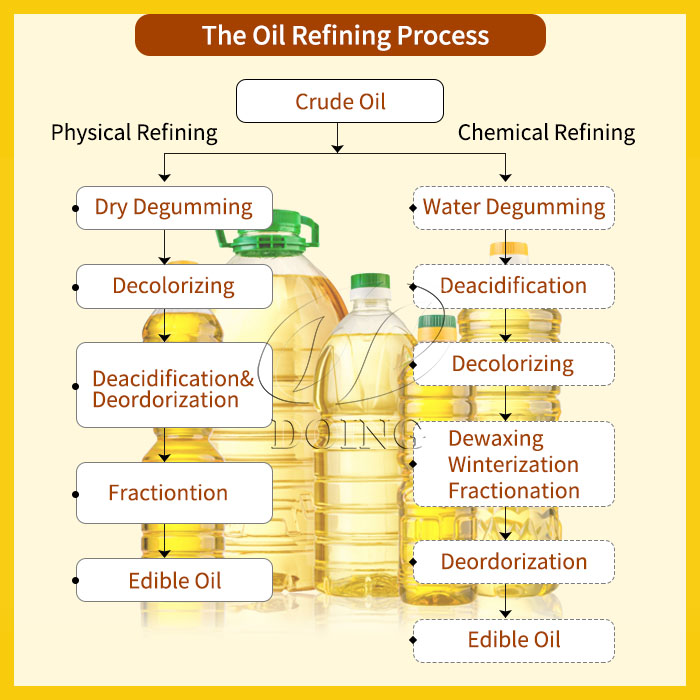

2. According to the classification of refining process, it can be divided into physical refining and chemical refining.

Physical refining and chemical refining

Physical refining and chemical refining

Chemical refining: basically applicable to all kinds of oil. The steps of chemical refining are: degumming, deacidification, decolorization and deodorization. Physical refining: suitable for oils with low gum content and high acid value, such as palm oil, palm kernel oil, coconut oil, etc.

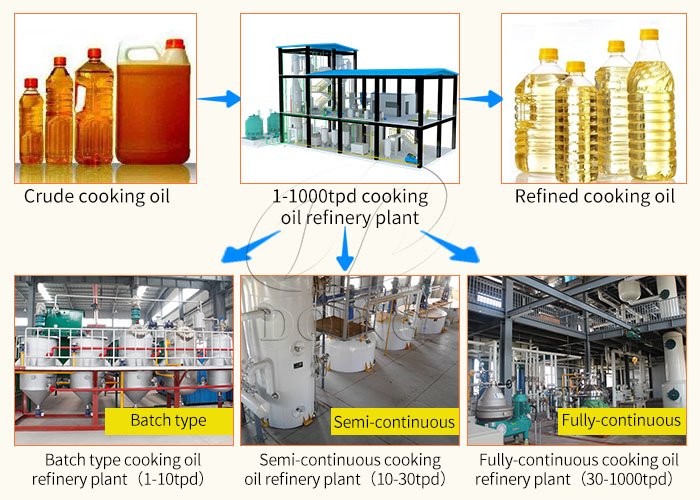

3. According to the size of the processing capacity, it can be divided into batch type cooking oil refining machine, semi-continuous cooking oil refining machine and full continuous cooking oil refining machine.

Cooking oil refining machine

Cooking oil refining machine

Batch cooking oil refining machine: generally used for oil refining of ≤20TPD. The advantages of batch refining are simple and flexible equipment operation, low investment, and suitable for frequent replacement of various oil products. The disadvantages are low oil yield, large loss, low work efficiency and unstable product quality.

Semi-continuous cooking oil refining machine: generally used for 5-30TPD refining Features: In general, the degumming and decolorization section is intermittent production; the deacidification and deodorization section adopts deodorization tower process for continuous production, realizing continuous refining, high efficiency, energy saving, economy, and additional output value high.

Fully continuous cooking oil refining machine: generally used for ≥30TPD refining. Advantages: The alkali refining section is equipped with a disc centrifuge (instead of the refining pot for natural sedimentation and separation of saponins, and the continuous production of each section of the full continuous refining is uninterrupted. The advantage of this design is that the production Small consumption, low oil loss, more stable refining quality.

Through the above introduction, do you know the types of cooking oil refining machine? Our engineers have more than ten years of project experience, the technology is very mature, and the quality of the refined oil obtained meets the national standard. If you are interested in our cooking oil refining business, please feel free to contact us!

Leave a message

If you wanna to get more details about How many types of cooking oil refining machine does Henan Glory Company have for sale?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company