What are the by-products of the cooking oil refining process? and how to use by-products?

All crude oil must be refined in order to meet cooking oil standards before it can be approved for sale in supermarkets. Refining is a complex production process, and different auxiliary materials need to be added to complete the entire production process. In order to remove different impurities in crude oil, how is refining carried out, what auxiliary materials need to be added during the refining process, and what by-products will be produced?

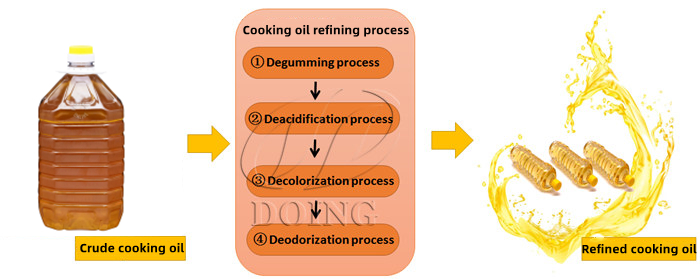

Cooking oil refining process

Cooking oil refining process

Refining includes degumming, deacidification, decolorization and deodorization. By-products formed during refining are mainly in the degumming and deacidification stages. First, raise the temperature in the refining tank to 70-80 degrees, and add an appropriate amount of hot water to the crude oil under high temperature conditions. The paddle in the tank is stirred and precipitated for 4-8 hours, and then the valve at the bottom of the refining tank is opened to release the precipitate (micelle).

Cooking oil degumming and deacidification process

Cooking oil degumming and deacidification process

In the process of degumming, we get the by-product - micelles. The micelles can be further processed to obtain different products, but they are also related to the raw materials. The most obvious is soybeans. The micelles made of refined soybean oil can be further processed to obtain different products. For example, soy isoflavones can be further processed. The estrogenic effect of soybean isoflavones affects hormone secretion, metabolic biological activity, protein synthesis, growth factor activity, and is a natural cancer chemopreventive agent. At the same time, the micelles can be further processed for animal feed.

Next, heat up again, add hot water and edible alkali (NaOH), precipitate again for 4-8 hours, open the valve, release the precipitate (saponin, available for sale), and complete degumming and deacidification. The saponins formed in this process are the raw materials for making soap.

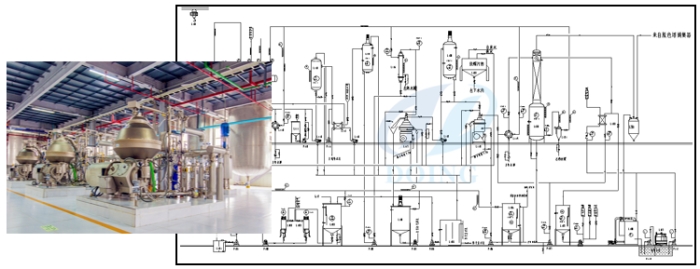

The specific by-products we get from the cooking oil refining process have a lot to do with our raw materials. But refining will definitely bring us different by-products and increase our income, so if you need cooking oil refining machine, it is recommended that you cooperate with Henan Glory Company, we will provide you with professional advice and high-quality cooking oil refining machine.

PREV:How to solve the problem of low quality cooking oil?

NEXT:What is the market price of sunflower oil refining machine?

Leave a message

If you wanna to get more details about What are the by-products of the cooking oil refining process? and how to use by-products?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company