What types of cooking oil refining method can be selected? Which one is better?

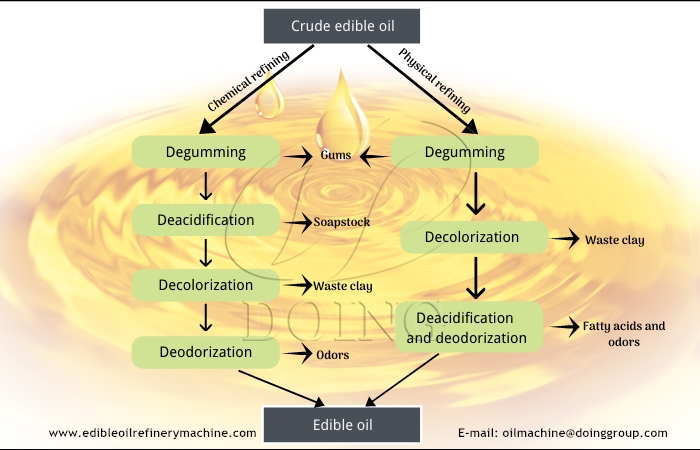

Edible oil refining is a relatively complex and flexible process. On the whole, there are two types of refining methods. The one is chemical refining, the other is physical refining. The main difference between the two types of refining method lies in how the FFA are removed. People maybe confused about how to choose the suitable refining method to produce edible oil. Because they don't know which refining method is better. Don't worry, in this article, I will make a introduction about this two types of cooking oil refining methods. And you can choose the best suitable method according to your requirements.

Recommended reading: What is the difference between physical refining and chemical refining of edible oil?

Chemical refining and physical refining of edible oil

Chemical refining and physical refining of edible oil

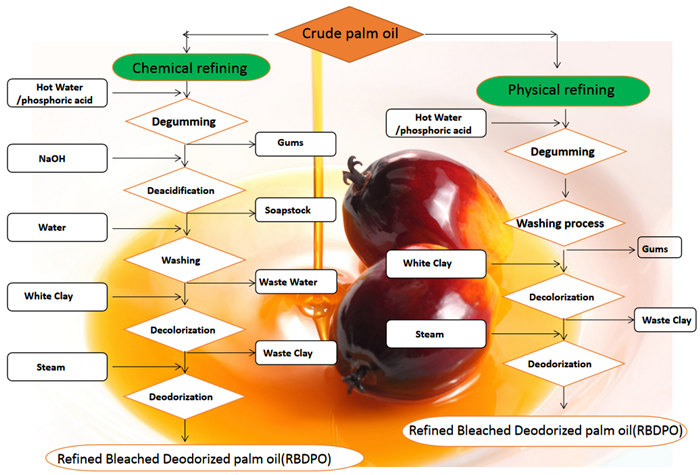

The first refining method is physical refining, the removal of FFA (free fatty acids) occurs during deodorizing process of refining process. Its refining process is degumming, decolorization, deacidification and deodorization.

In degumming process, it mainly uses the hydrophilicity of phospholipids to remove natural gums by adding hot water or food grade phosphoric acid to the crude edible oil. Then, in bleaching process, it mainly uses the activated clay to adsorb the colouring matters or other metal ions under vacuum. While the deacidification and deodorization process is under high temperature and low pressure. By using steam, the FFA can be removed. What's more, the off-flavors and odours can also be removed from the crude edible oil in the steam distillation process.

Chemical refining and physical refining of palm oil

Chemical refining and physical refining of palm oil

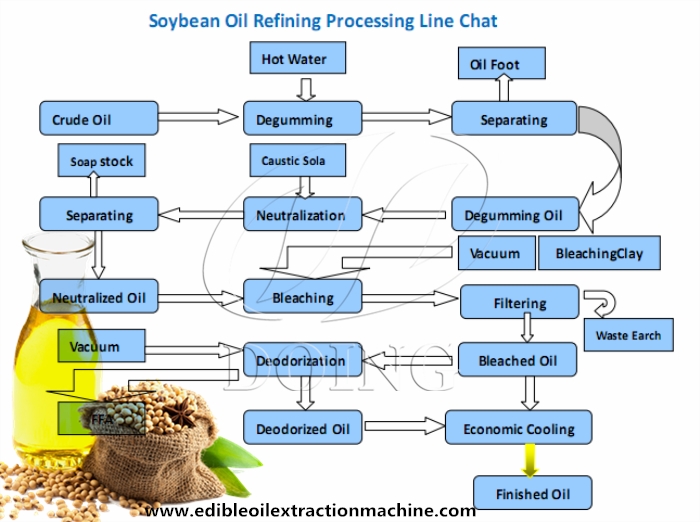

The second refining method is chemical refining, the removal of FFA (free fatty acids) occurs during deacidification process of refining process. The basic refining process is degumming , deacidification, decolorization and deordorization.

1) Degumming process:

We mainly use hydration degumming process to remove gums from crude edible oil with the help of phosphoric acid.

2) Deacidification process:

We mainly use acid-base neutralization method to remove FFA, during this step, we can get soapstock which is the raw material of soap production line.

3) Decolorization process:

Same with physical refining method, the decolorization process of chemical refining is also uses white clay to adsorb unwanted pigments and other metal ions to let the color of edible oil will become much lighter.

4) Deodorization process:

The purpose of deodorization process is to remove unacceptable odors by steam distillation. In the deodorization process, the odoriferous compound are stripped off by injecting steam into heated oil under high vacuum pressure.

Soybean oil chemmical refining process

Soybean oil chemmical refining process

Hoping this article can help you have a brief understanding of chemical refining and physical refining. As for which types of refining methods is more suitable for you, you need to decide based on the characteristics of your raw materials and the final product you want to get. You only need to tell us your specific requirements, that our engineers will provide you many useful information about your edible oil refinery plant projects.

PREV:What types of edible oil refinery plant are available?

NEXT:Why people tend to choose small scale edible oil refinery plant to produce cooking oil?

Leave a message

If you wanna to get more details about What types of cooking oil refining method can be selected? Which one is better?, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

Henan Glory to Supply 1TPD Edible Oil Refinery Machine to Guinea Client

-

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

Henan Glory Secures Central Africa Order for Small Edible Oil Refinery Plant (200kg/d)

-

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

Nigeria: 50TPD Palm Oil Refining & 30TPD Fractionation Equipment Deal Signed

-

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

Burundi Client Boosts Oil Quality with 5TPD Palm Oil Fractionation Machine from Henan Glory

-

The soybean oil refining machine has been successfully shipped to Nigeria

The soybean oil refining machine has been successfully shipped to Nigeria

-

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company

A Nigerian customer successfully placed an order for edible oil refining equipment manufactured by Henan Glory Company