Soybean oil extraction plant is used to derive oil from soybeans, including pressing and solvent extraction. We are the manufacturer of soybean oil extraction plant. Here we will introduce the mian parts of the soybean oil extraction plant (solvent extraction).

As manufacturer of soybean oil extraction plant, we can offer whole line or part of soybean oil extraction plant with general capcity from 10TPD to 6000TPD. For special capacity, our engineer can also help design and install workshop according to your capacity and requirements.

1.Pretreatment part of the soybean oil extraction plant:

Soybean → Cleaning → Crushing → Softening → Flaking → Puffing (Drying) → Solvent extraction

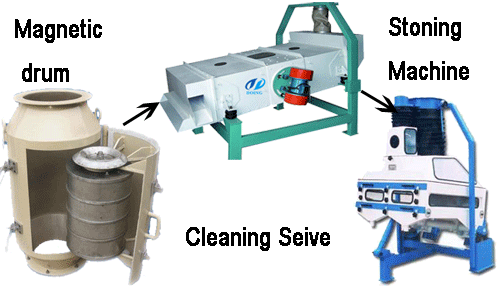

a. Cleaning :

Cleaning section removes impurities in soybeans through magnetic drum, cleaning seive, stoning machine, etc. Soybeans from different regions need different cleaning machines to remove impurities. And our engineer can help you choose most suitable sets of cleaning machines according to your material.

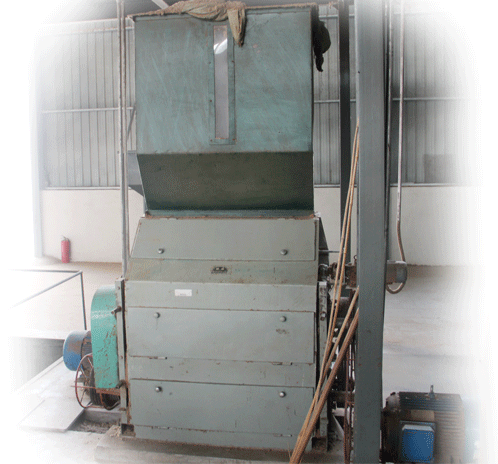

b. Crusher:

It is used for crushing soybean into small pieces, which can help to extract more oil from the seeds.

c. Softening Machine/pot:

This is a special step for soybean oil making. This step improves the ductility of soybean. Then the flakes will be thin and not fragmentary. It can reduce the fines content effectively.

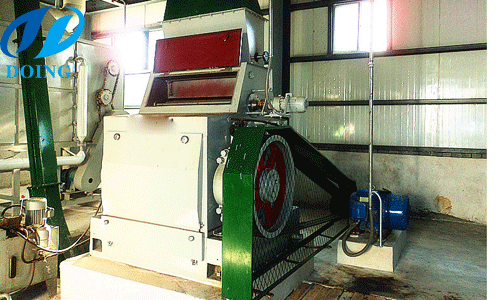

d.Flaking Machine/Flake roll:

This machine can be made the soybean to 3mm-5mm flakes , it will destroy the soybean oil cell which is easy extraction oil out.

|

Totocel Extractor

|

Loop type extractor

|

|

|

|