1: Fully Continuous Edible Oil Refinery products

Introduction of automatic cooking oil refinery machine

2: Fully Continuous Edible Oil Refinery products

Introduction of automatic cooking oil refinery machine

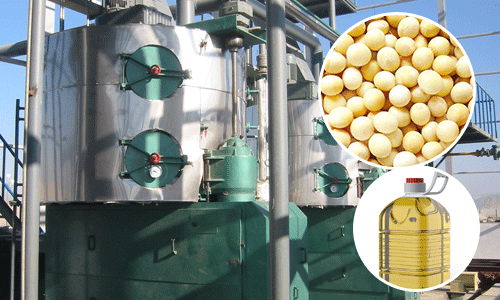

3: Fully Continuous Edible Oil Refinery products

Introduction of automatic cooking oil refinery machine

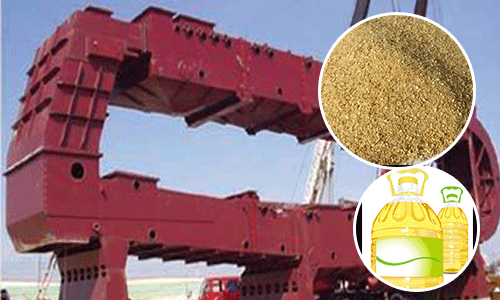

4: Fully Continuous Edible Oil Refinery products

Introduction of automatic cooking oil refinery machine