According to different capacity and technology, the edible oil refinery can be divided into three ways which including batch oil refinery, semi-continuous oil refinery and continuous oil refinery. Batch oil refinery is the simplest technology, so the cost of it is also smallest.

1.The extra boiler is not needed, so it has wide scope of application.

2.The combination of short mixing and long mixing ensure the quality of washing.

3.The leaf filter is used in the decolorization section. The advantages of it is simple operation, less worker, oil residues is less in the white clay.

4.It can be used to refine various edible oil, after changing the temperature of water.

5.The quality of final oil is stabilize.

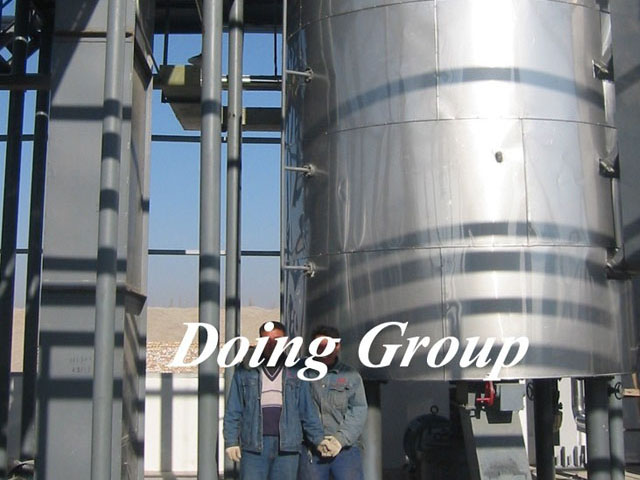

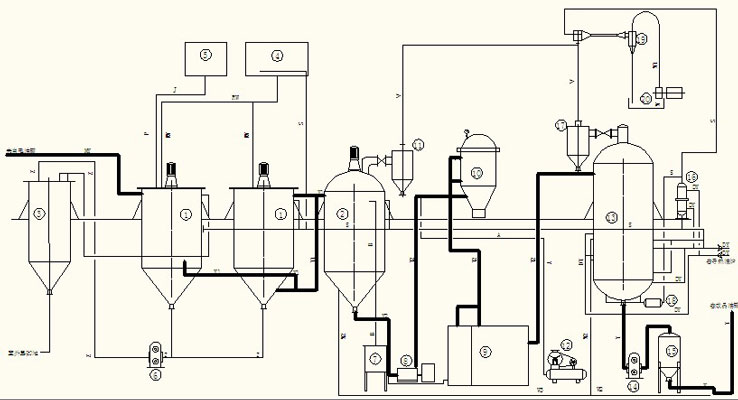

Neutralization pot: to move the acid in the edible oil and washing the oil.

Decolorization pot: to move the pigment in the oil.

Deodorization pot: to move the pungent taste in the cooking oil.

Conductive oil stove: It is used to provide the heat for the whole process.

Vacuum pump: The function of it is to provide vacuum for decolorization and deodorization.

Air compressor: It will dry the white clay after absorb the pigment in the oil.

Steam generator: To generate the steam for the deodorization pot.

Technical Parameters

|

Consumption Item |

Capacity |

|

Steam |

700Kg/T |

|

Electricity |

28Kwh/T |

|

Water |

150Kg/T |

|

Phosphoric acid |

2-3Kg/T |

|

Alkali |

Acid value X1-3Kg/T |

|

Water circulation and cooling water |

150m³/H |

|

White clay |

3-5Kg/T |

|

Oil in the waste white clay |

<25-35% |

|

Oil consumption in neutralization |

Acid value X1.2(chemical way) |

|

Acid value X0.6(physical way) |

|

Oil consumption in decolorization |

White clay X0.25% |

|

Oil consumption in deodorization |

≤0.5% |

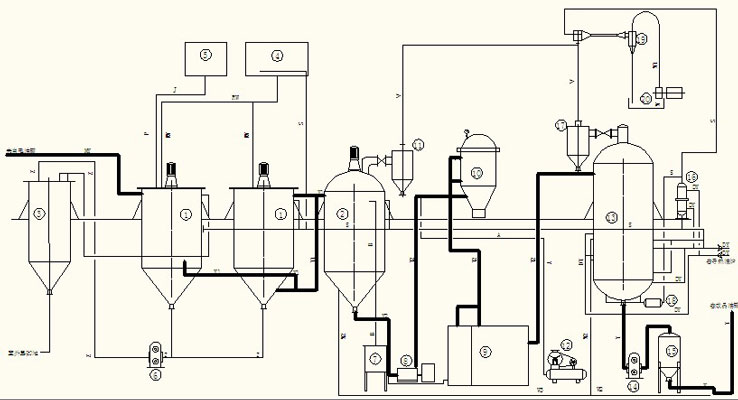

Flowchart of batch oil refinery

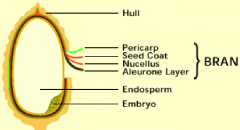

The batch oil refinery plant can be used to produce 1st and 2nd grade oil from crude vegetable oil. It also can process animal oil, such as fish oil, pig oil, duck oil and so on. The suitable capacity is 1-30T per day.

However, different oils have different processes. Our engineer can help you choose most suitable oil refinery plant according to your capacity and requirements. If you want to know more about oil refinery plant, please do not hesitate to contact us.