Rice bran oil refinery plant

Rice bran oil refinery plant is an indispensable part in the process of making rice bran oil. The rice bran oil obtained after the rice bran is pressed or leached is called crude rice bran oil, which contains more substances harmful to human, and influence the time of storage and the quality of the product.

The impurities contains in crude rice bran oil: moisture, free fatty acids, complex lipids (such as glycolipids, phospholipids, proteoglycans), waxy, olfactory substances, pigments, and so on. All of these can be removed by rice bran oil refinery plant.

Different capacity of batch type rice bran oil refinery plant

Different capacity of batch type rice bran oil refinery plant

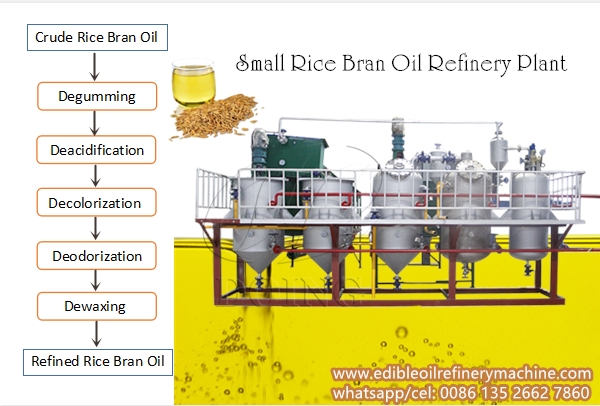

Same with sunflower oil refinery plant, rice bran oil refinery plant also need dewaxing process. Without dewaxing process, the rice bran oil is not healthy, unqualified to food standards. Before dewaxing process, there is degumming, de-acidification, decolorization, and deodorization processes in rice bran oil refinery plant.

Rice bran oil refining process flow chart:

Rice bran oil refining process flow chart

Rice bran oil refining process flow chart

Functions of each step of rice bran oil refining process:

1. Crude rice bran oil degumming:

In this step gums in crude rice bran oil are removed by hydration with the help of phosphoric acid.

2. Deacidification (neutralization):

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Decolorization:

During decolorization, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization:

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure.

5. Dewaxing (necessary for rice bran oil):

Rice bran oil dewaxing plant reduce wax content in rice bran oil, which help increase edibility of rice bran oil.

Advantages of rice bran oil refinery plant:

1. The impurity of oil must be less than 0.2% after refining;

2. Recycling system save power and money;

3. Lower oil waste.

Henan Doing Company has been specialized in manufacturing rice bran oil refinery plant since 1967. We can offer turnkey service of rice bran oil refinery plant and our professional engineers can help you design and install your rice bran oil refinery plant according to your real conditions. Waiting for your enquiry!

Leave a message

If you wanna to get more details about Rice bran oil refinery plant , you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?