Canola/ rapeseed oil refinery plant

Same with other vegetable oil refinery plant, canola/ rapeseed oil refinery plant includes degumming, deacidification, decolorization, and deodorization. Through these four steps, the crude canola/ rapeseed oil will become refined canola/ rapeseed oil.

The introduction of canola/ rapeseed oil:

Rapeseed oil, also known as canola oil, is a transparent or translucent liquid obtained from the seeds of rapeseed. Rapeseed oil is golden or brown in color and has a certain stimulating odor. This gas is caused by a certain amount of mustard glycoside, but rapeseed of superior varieties does not contain this substance.

The introduction of batch type canola/ rapeseed oil refinery plant:

Batch type rapeseed oil refinery plant with different capacities

Batch type rapeseed oil refinery plant with different capacities

Batch type canola/ rapeseed oil refinery plant is mainly made up with four tanks: two refining tanks, decolorization tanks and deodorization tanks. Low cost, easy operation and it is the best choice for small rapeseed oil refinery plant.

Cotinuous rapeseed oil refienry plant:

Continuous rapeseed oil refinery plant model picture

Continuous rapeseed oil refinery plant model picture

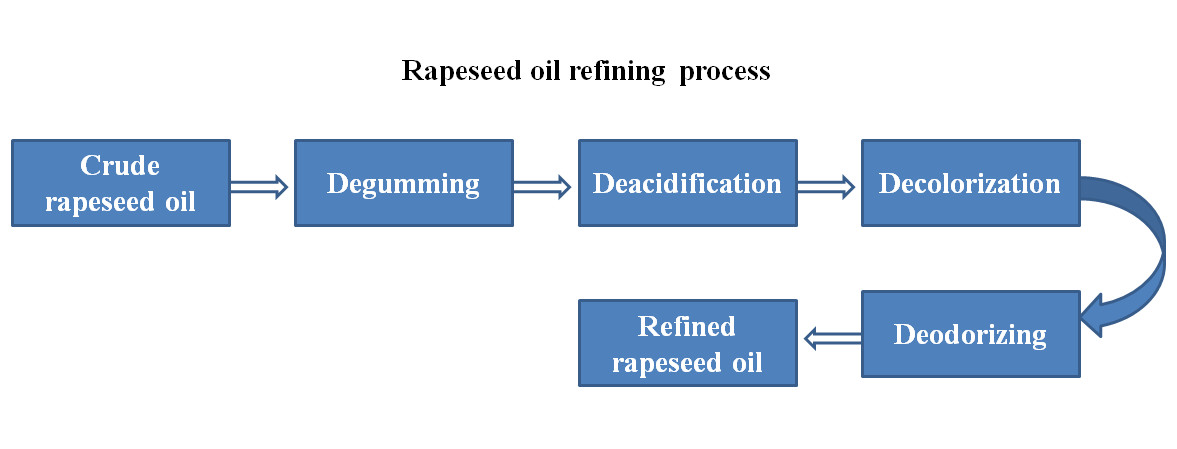

Craft flow for canola/ rapeseed oil refinery plant:

Rapeseed oil refining process flow chart

Rapeseed oil refining process flow chart

Main functions of different steps in rapeseed oil refining process:

1.Degumming: Degumming removes gums as preparation for subsequent refining processes.

2.Deacidification: Deacidification removes FFA (free fatty acid) in crude oil.

3.Decolorization: Decolorization removes pigments in crude oil by adding white clay, which can improve the oil quality.

4.Deodorization: Deodorization removes odor in crude oil, which can improve the flavor, stability, color and quality of the oil.

Machines used in rapeseed oil refinery plant

Machines used in rapeseed oil refinery plant

The purpose of canola/ rapeseed oil refinery plant:

Rapeseed oil refinery plant is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude rapeseed oil, to get some standard rapeseed oil.

This is a brief introduction of rapeseed oil refinery plant. Doing Company is a professional edible oil refinery plant manufacturer. Our engineers can help you design and install rapeseed oil refinery plant according to your capacity and requirements. To know more information about rapeseed oil refinery plant, please contact us.

Leave a message

If you wanna to get more details about Canola/ rapeseed oil refinery plant, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.

-

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

What Impurities Can Edible Oil Refinery Machine Remove during Processing?

-

Full Analysis of Batch Type Sunflower Oil Refining Equipment

Full Analysis of Batch Type Sunflower Oil Refining Equipment

-

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

Why is Using a Groundnut Oil Refining Machine Essential for Oil Quality?

-

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

Food-Grade Palm Oil Production: Critical Machines for Refining Palm Oil

-

What are the components of sunflower oil refinery plant?

What are the components of sunflower oil refinery plant?

-

What machines does a 10tpd crude cooking oil refining line include and how much is the price?

What machines does a 10tpd crude cooking oil refining line include and how much is the price?